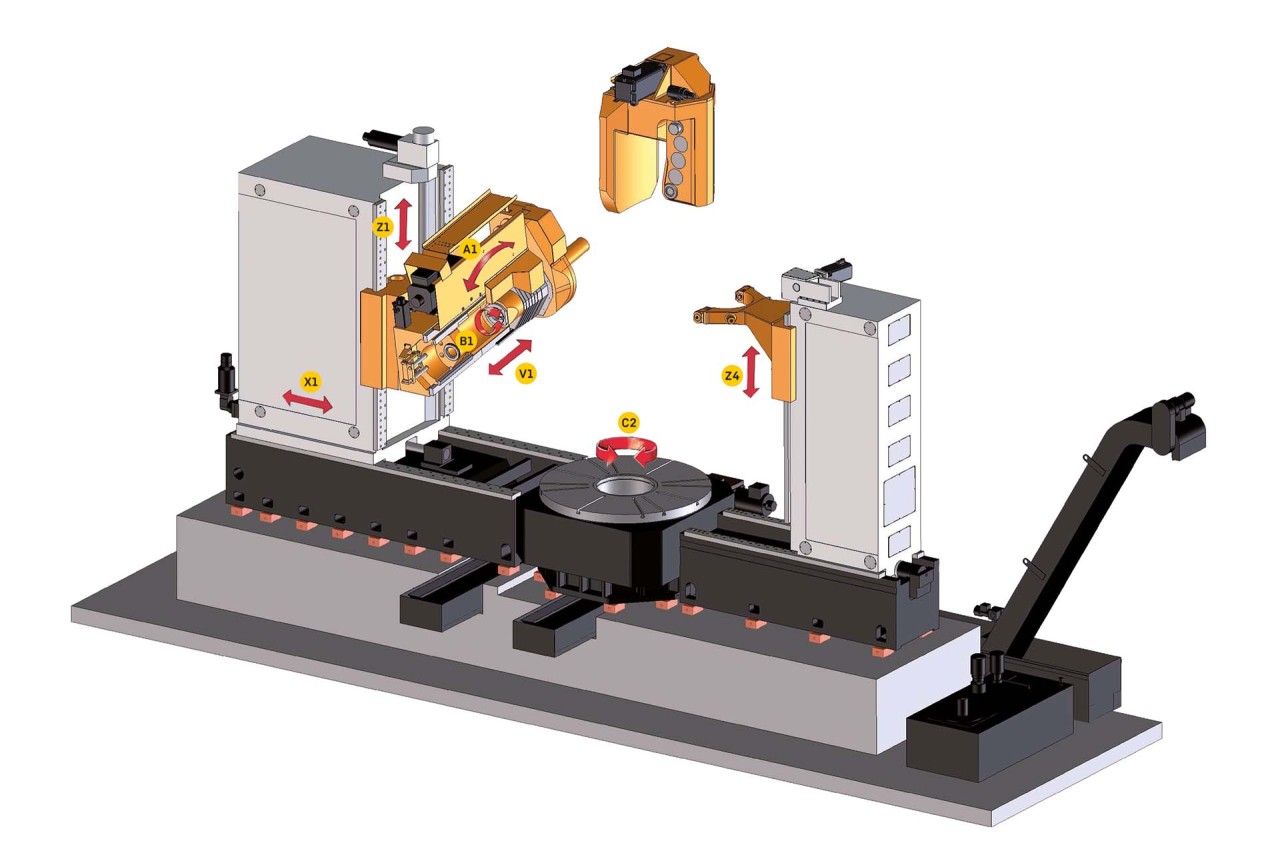

Machine concept

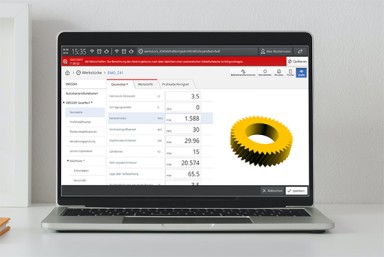

Is performance-related gear cutting possible on your machine? As nowadays the need to be economical is more important than ever, modern machines are required.

The Liebherr LC series ensures reliable machining with the required torques and cutting forces. This allows us to reinforce the capability of modern CNC gear hobbing machines.

The machine concept fulfills quality requirements such as accuracy, stability and temperature resistance. Stable processes are realized during pre- and finish cutting.

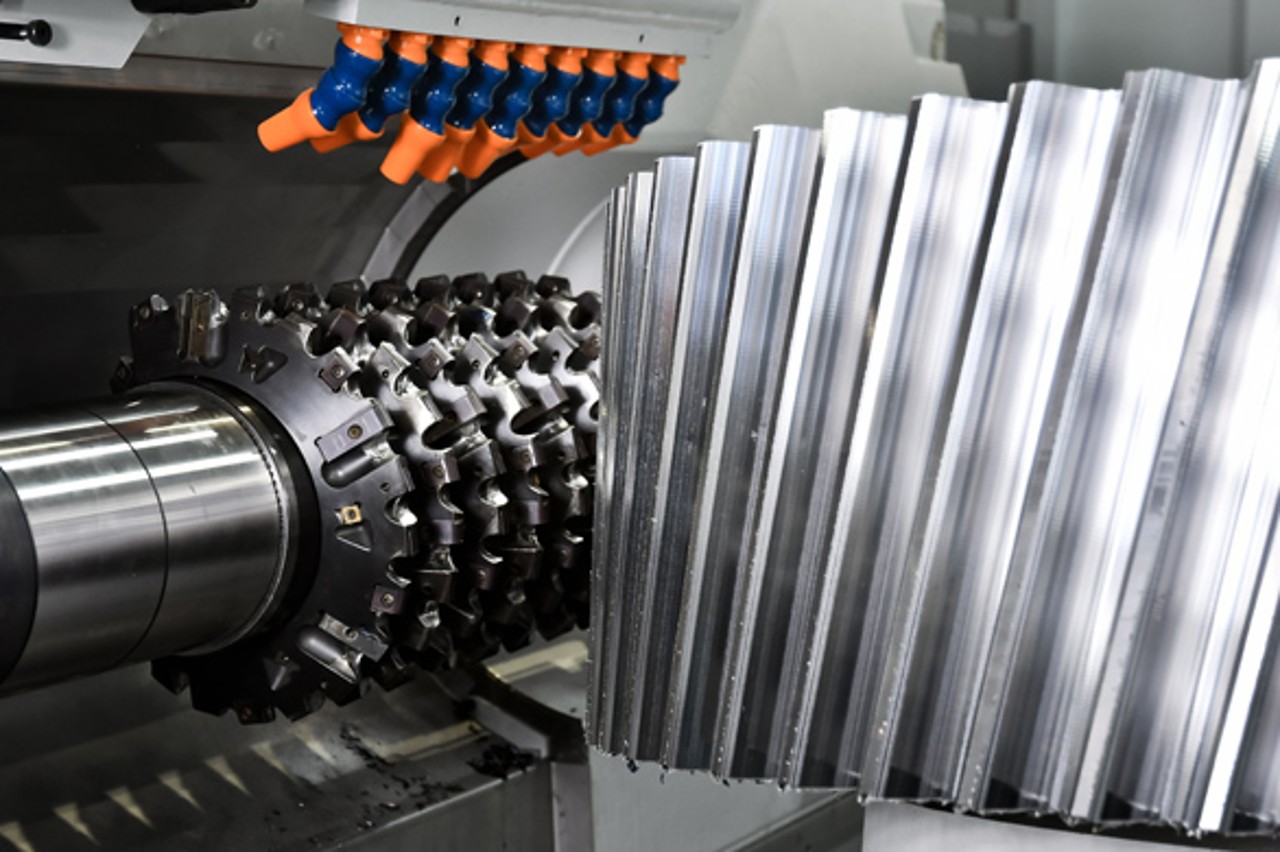

Is dry gear hobbing for large modules (m>10) possible? Yes, as you can see in the picture on the left.

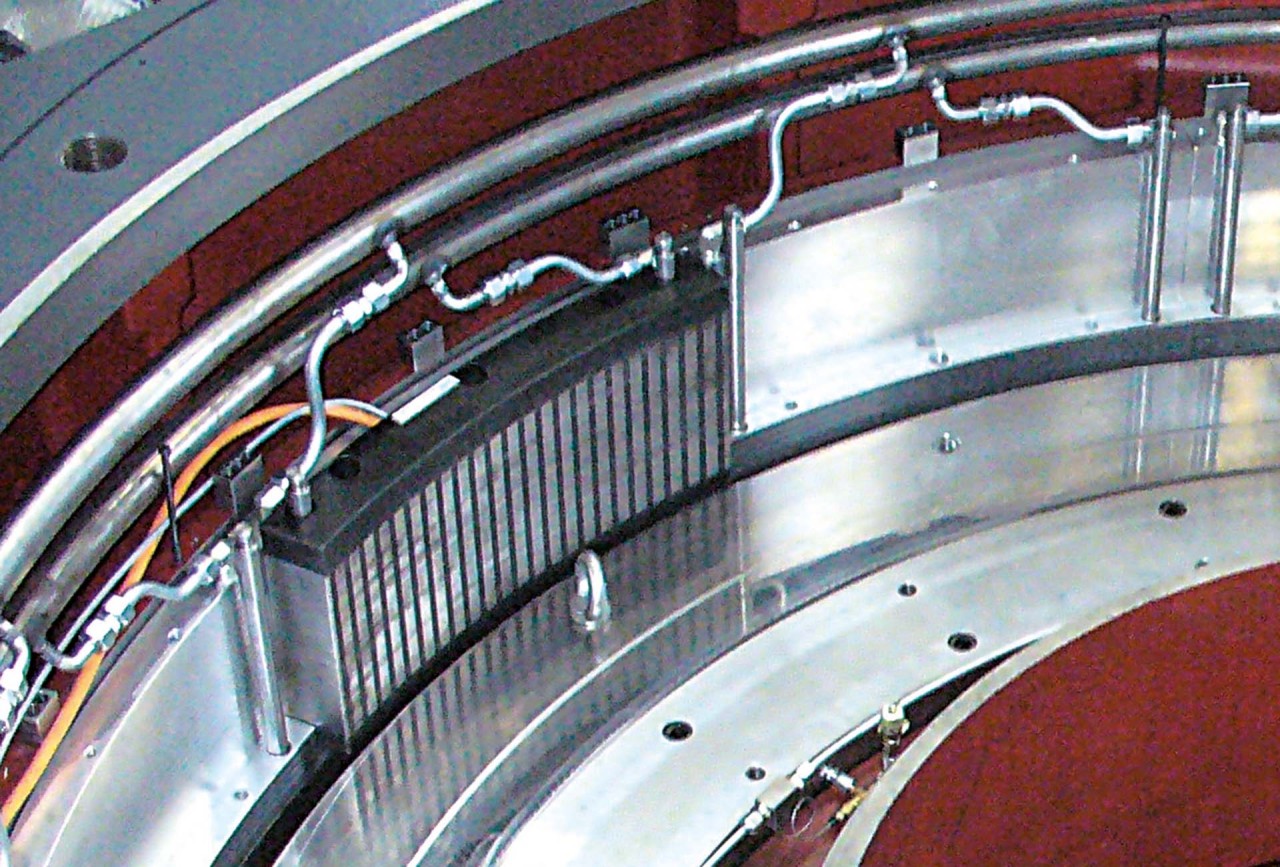

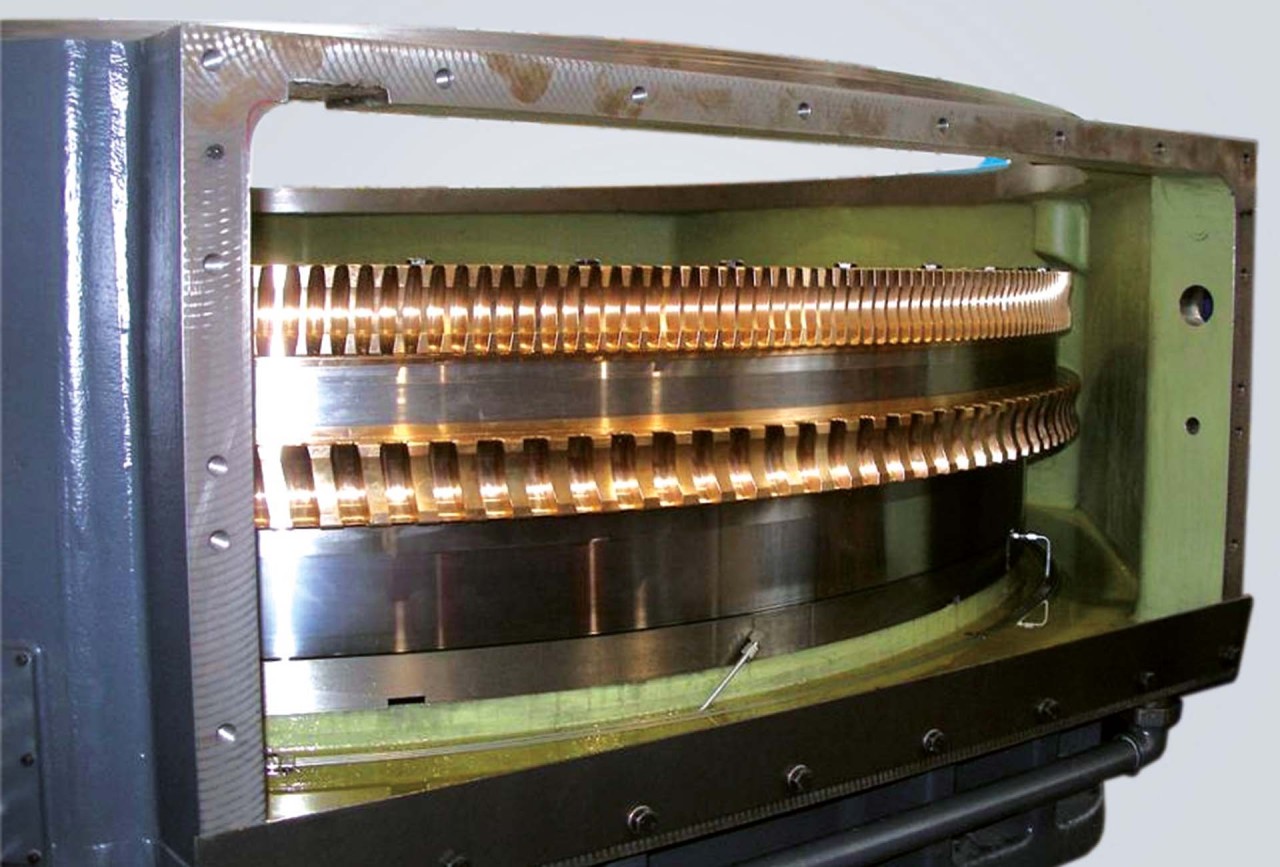

Hob heads

Impressions

Technical data

| Variants | LC 1500 | LC 2000 | LC 2500 | LC 3000 | LC 4500 | LC 6000 | LC 8000 | LC 10000 | LC 12000 |

|---|