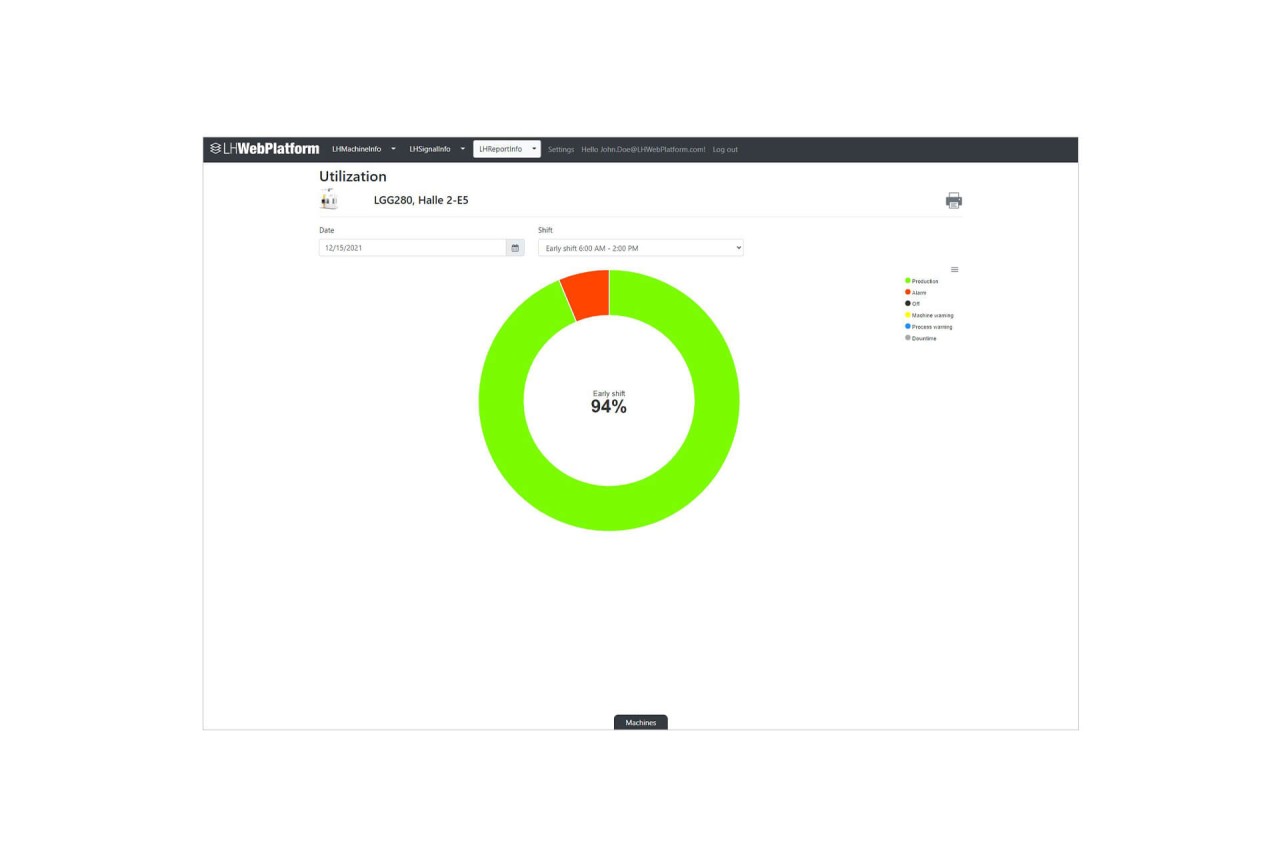

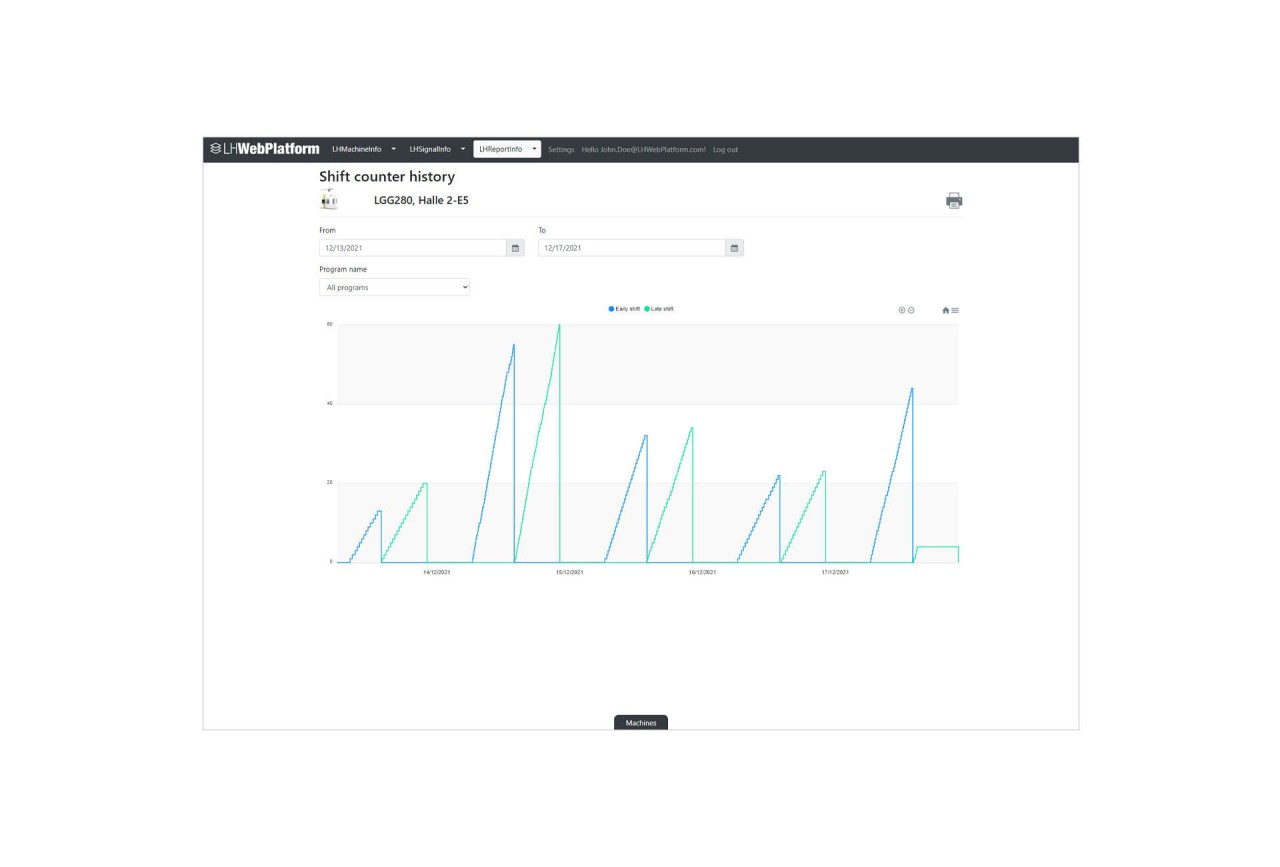

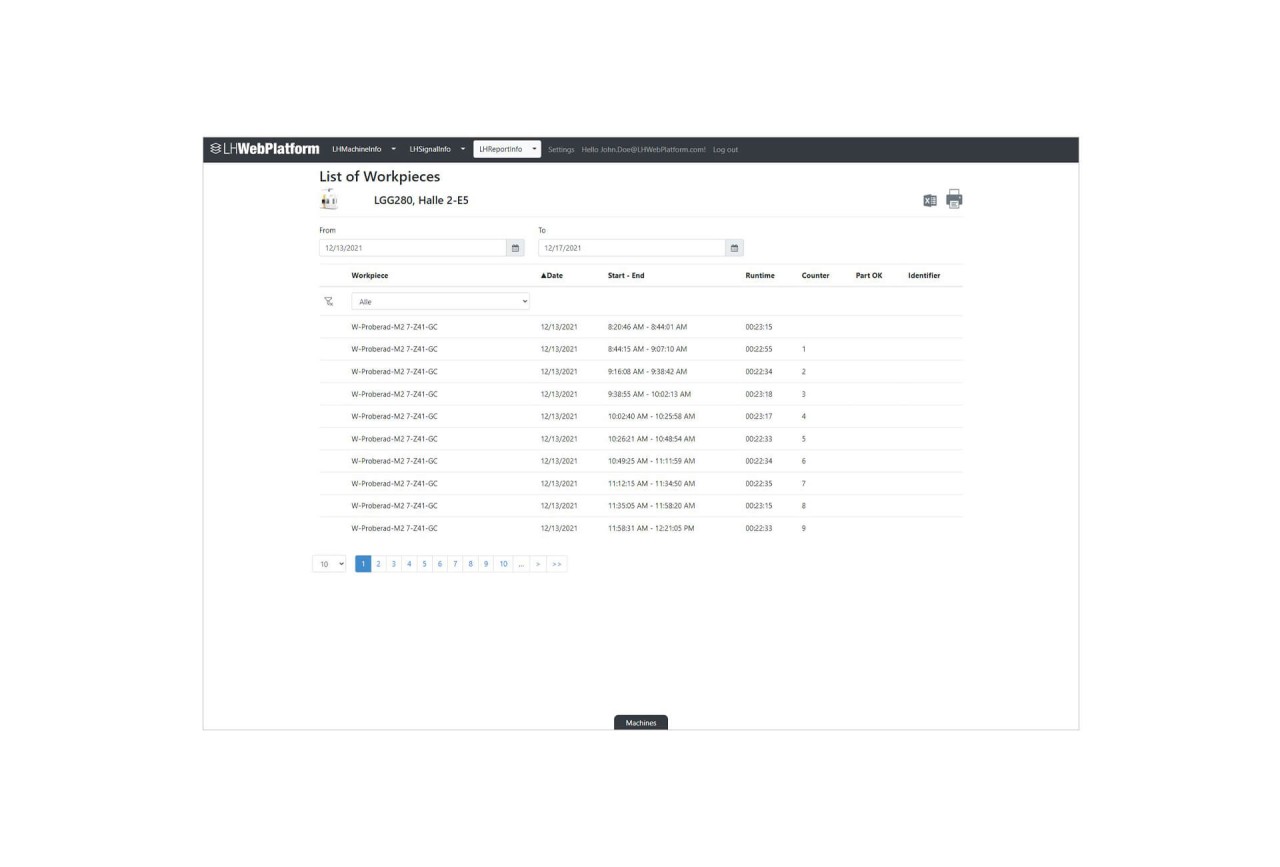

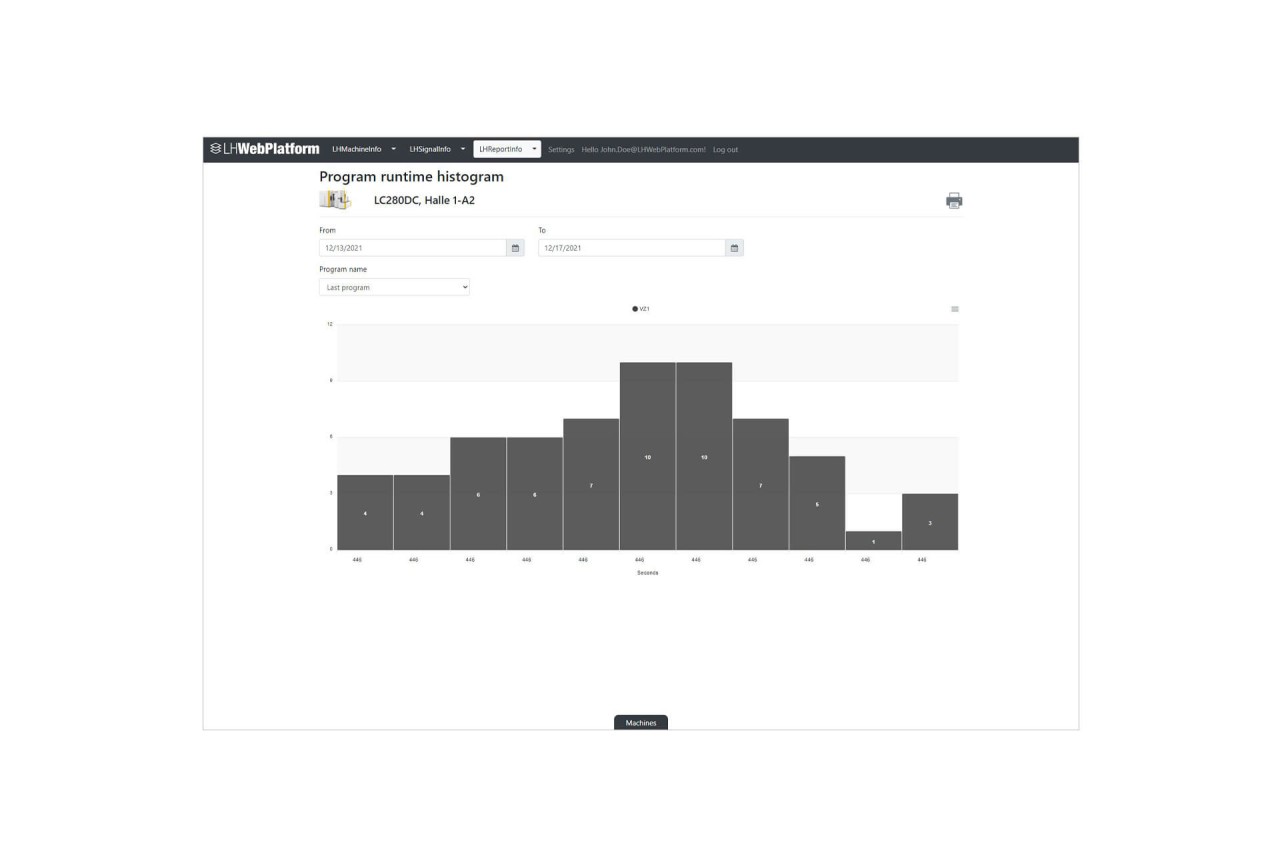

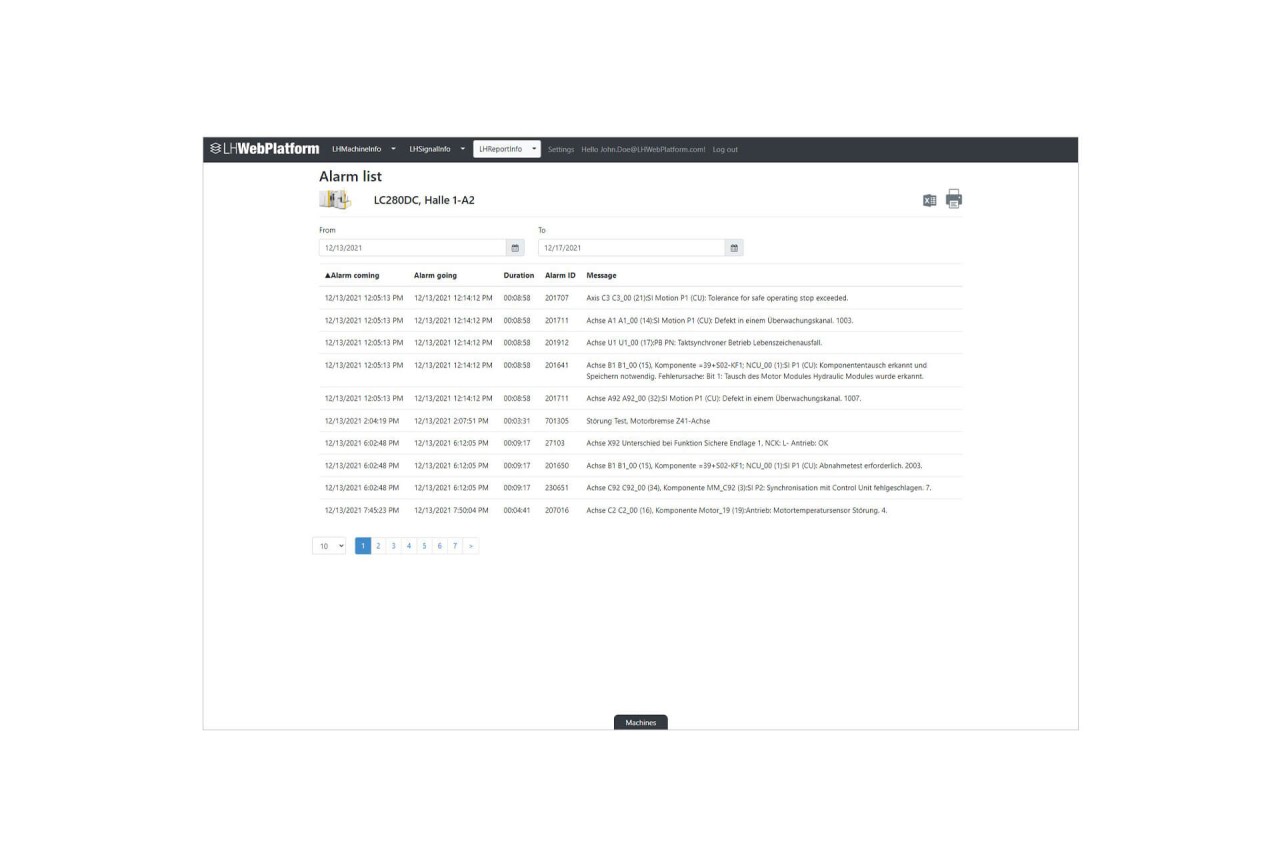

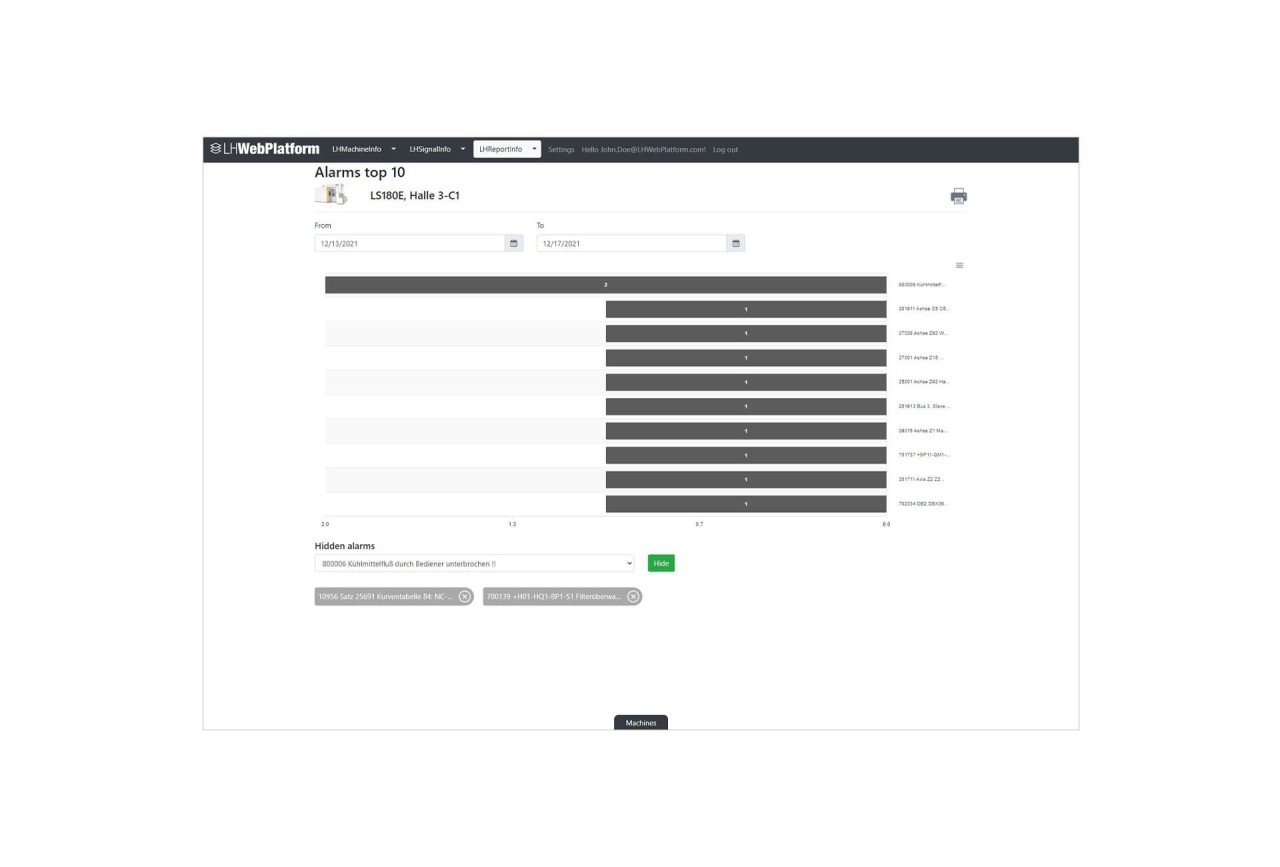

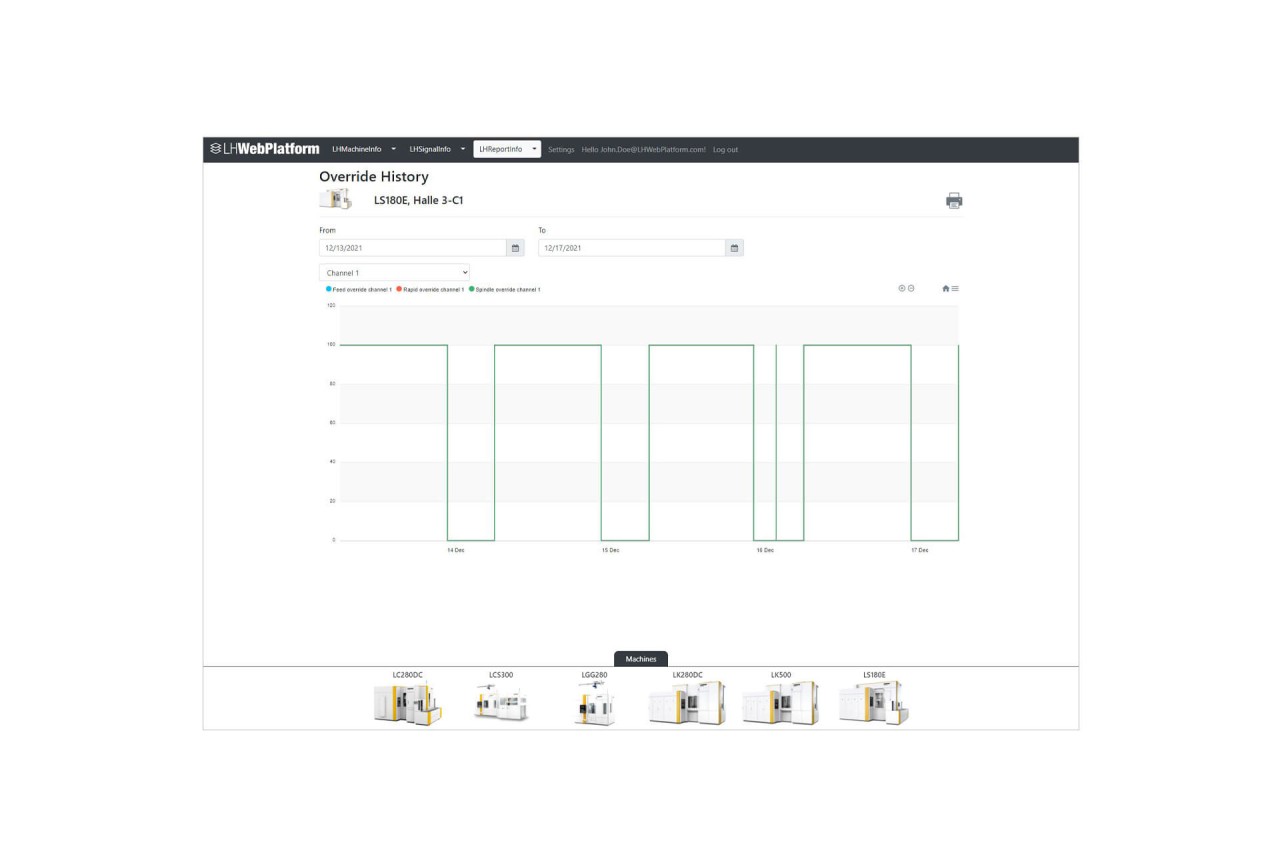

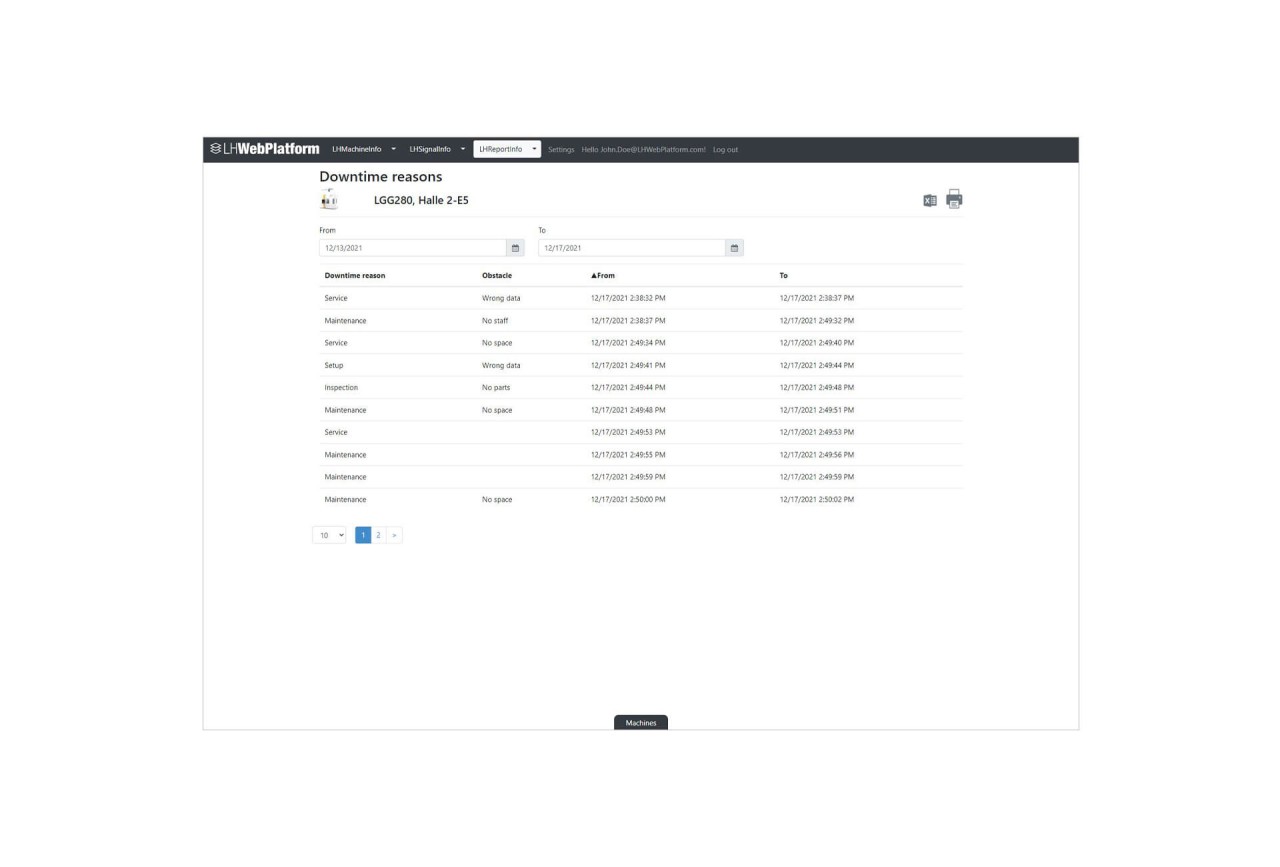

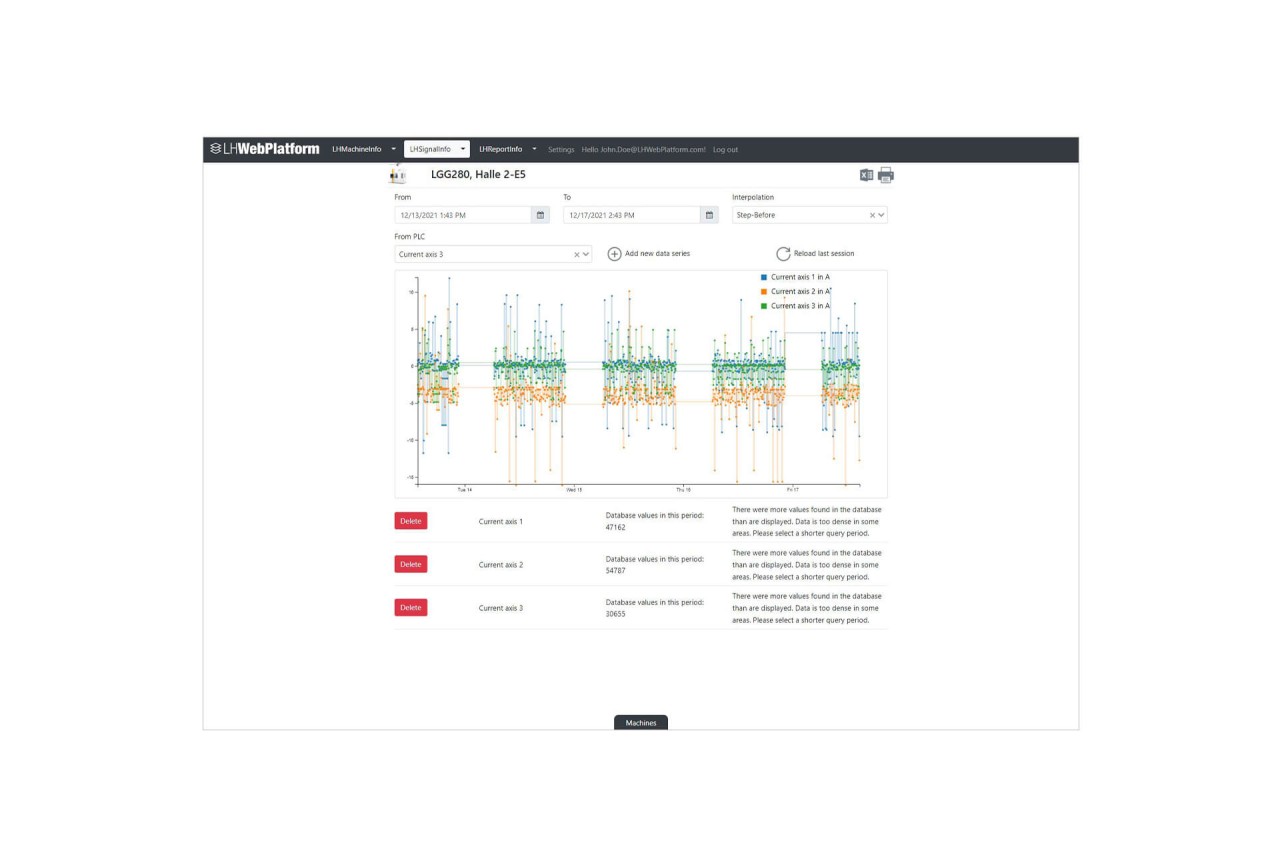

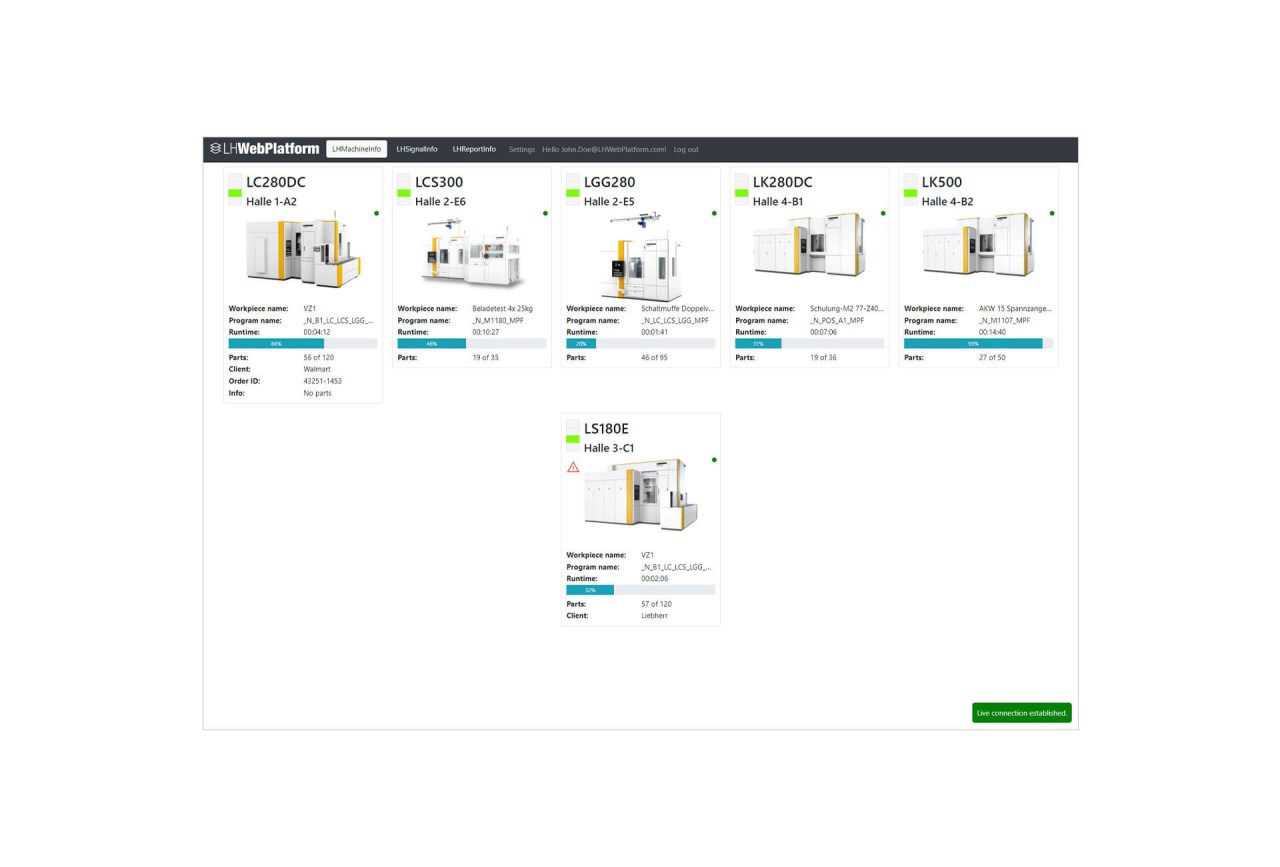

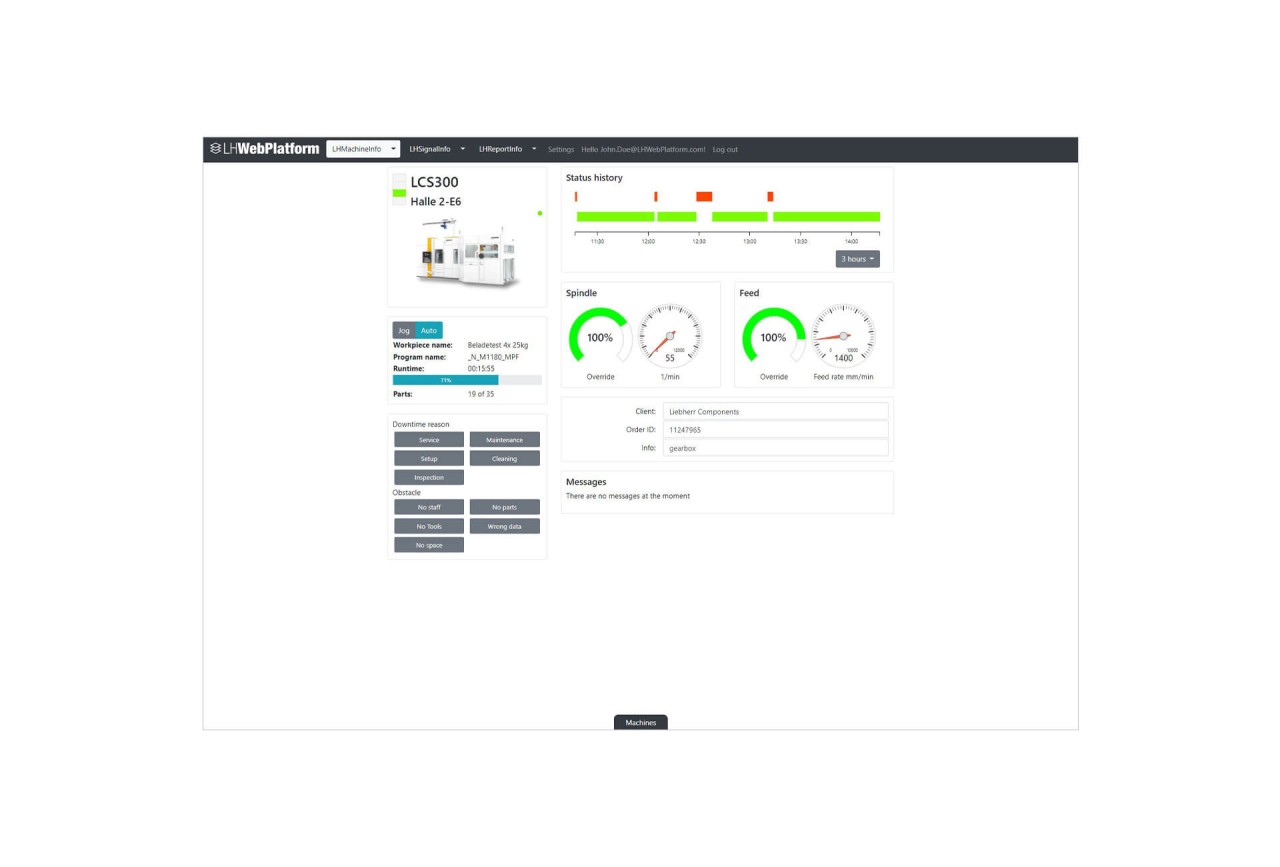

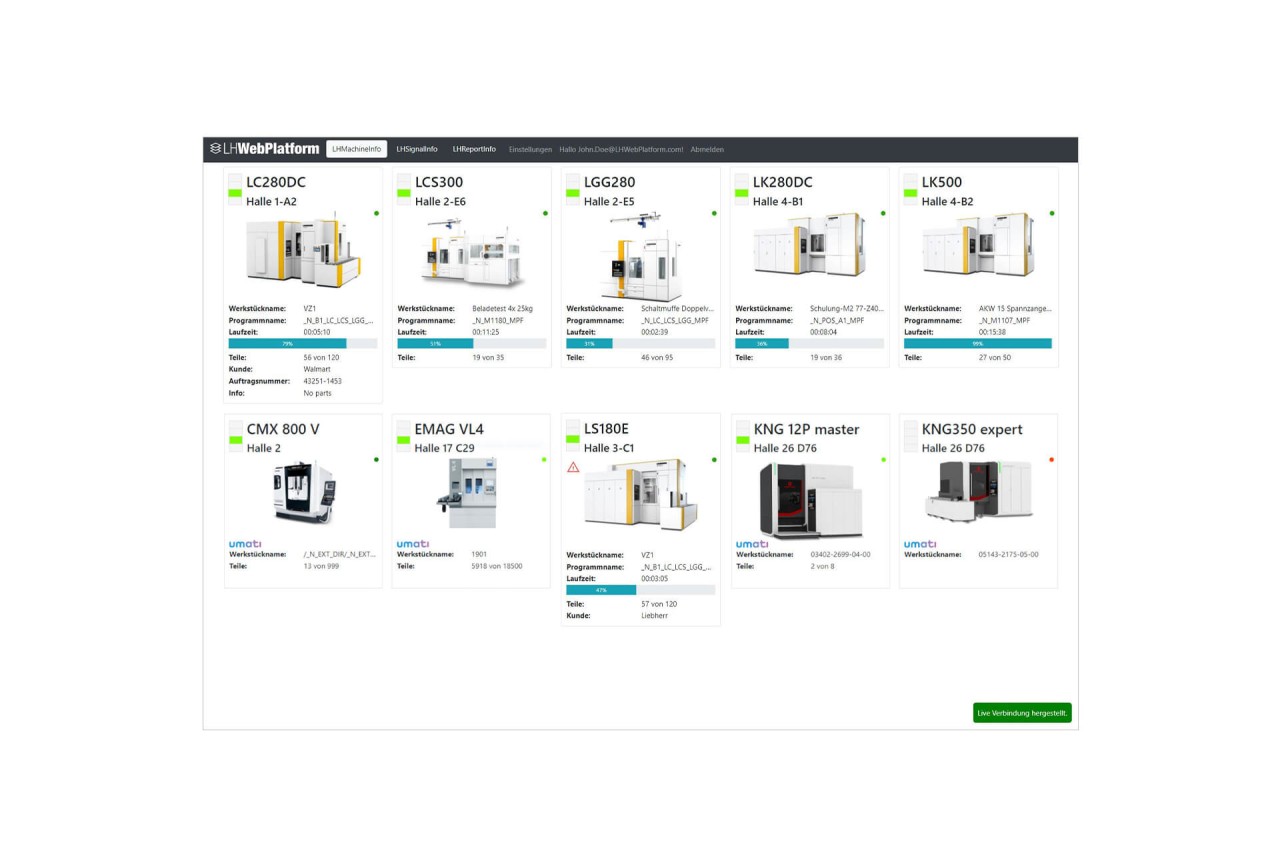

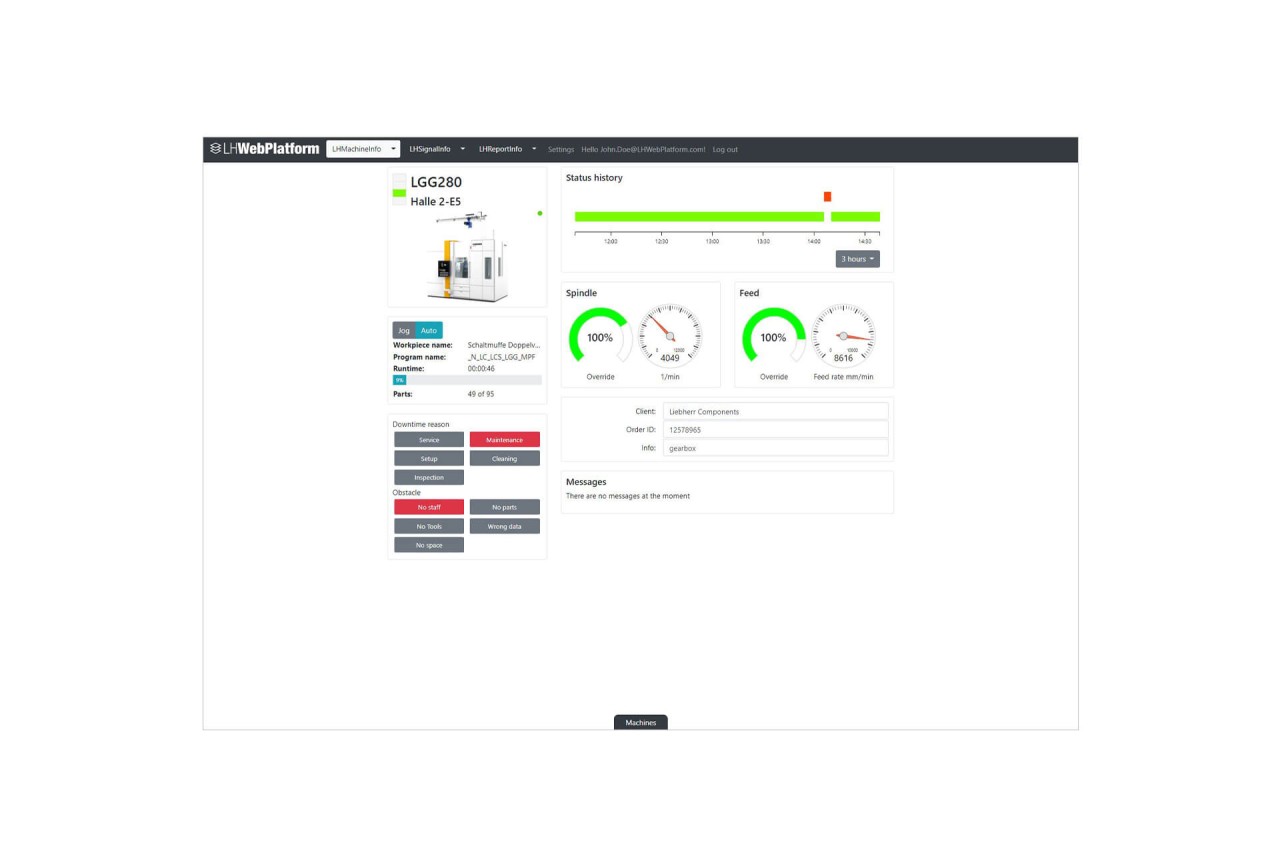

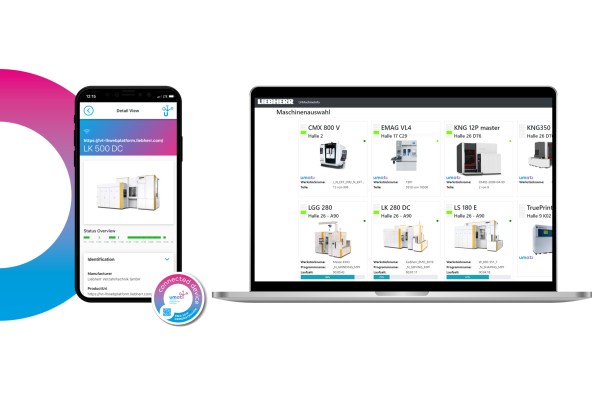

LHWebPlatform – the basis for your digitization projects

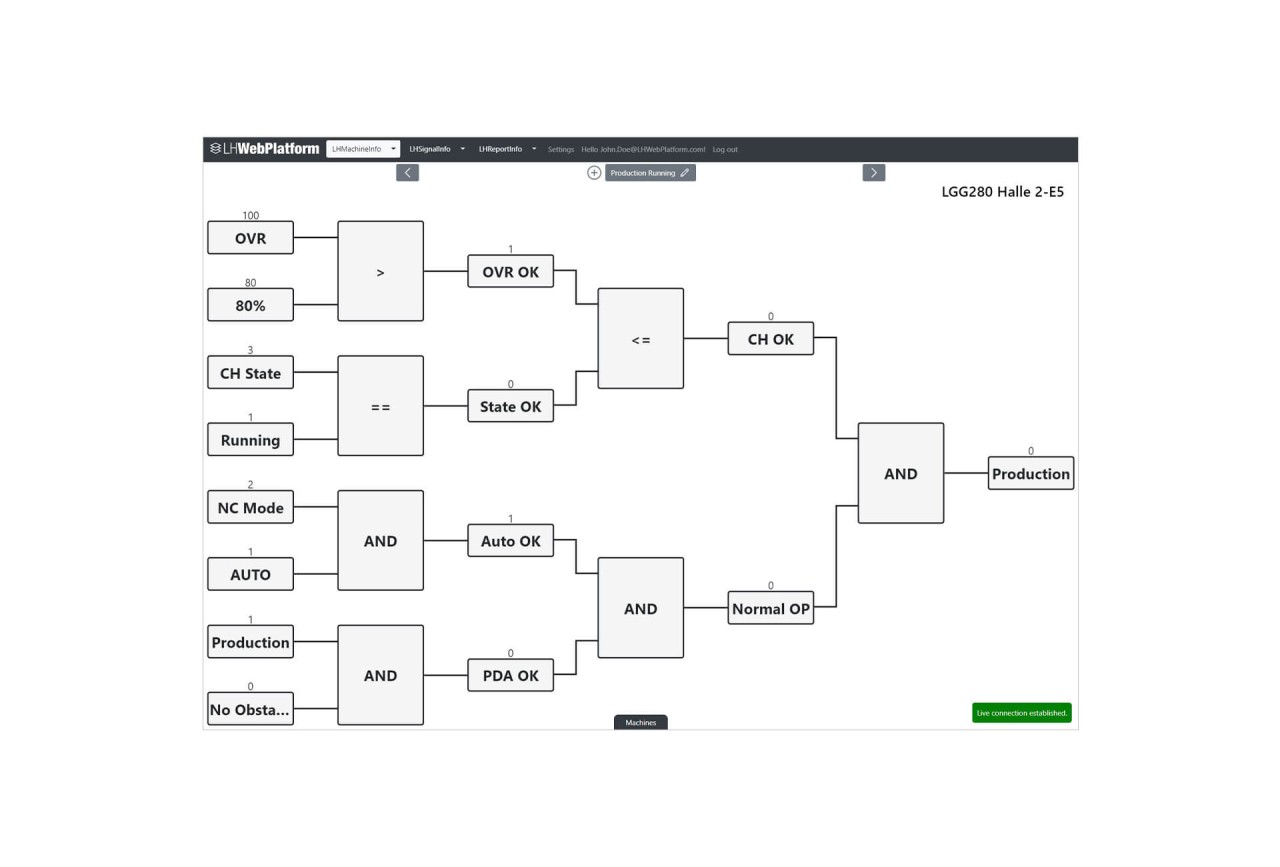

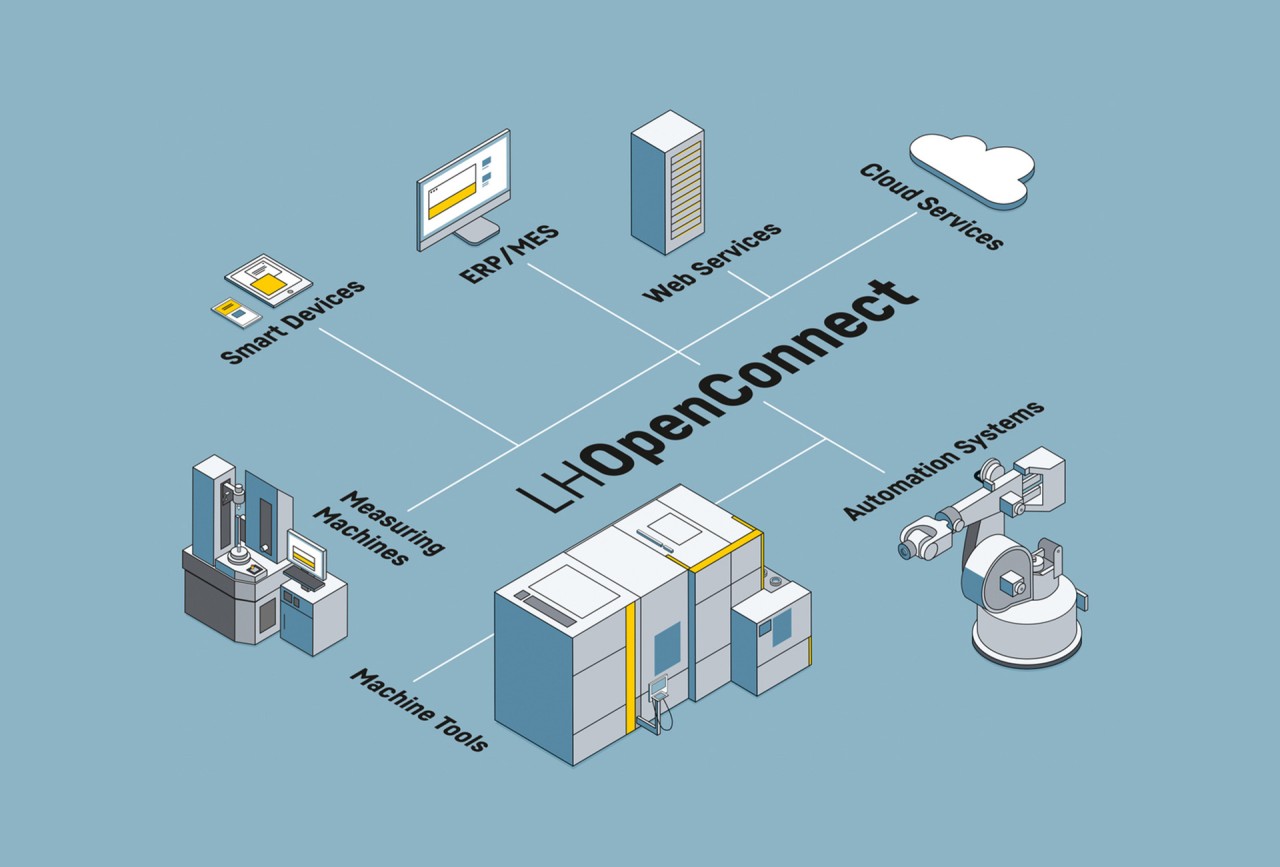

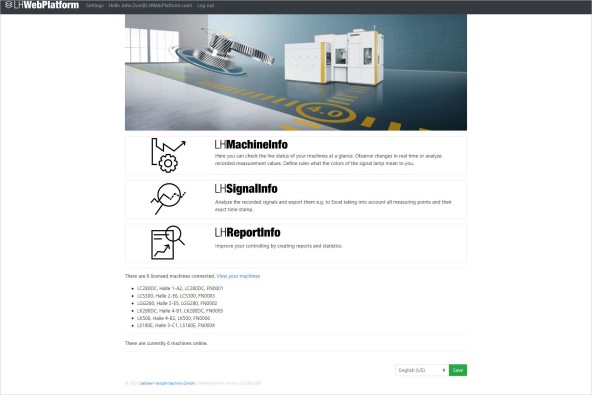

Liebherr offers a modular platform consisting of data profiles, interfaces and the various LHWebPlatform apps. These elements can be used to develop customized solutions which are tailored perfectly to the requirements of the customer. The spectrum of applications ranges from simple monitoring tasks to far-reaching industry 4.0 scenarios – such as process logging, manufacturing analysis and production optimization. A wide variety of transmission paths and protocols – from fieldbus (Profibus, Profinet) to OPC-UA or also umati – enable the connection of the machines, for example to your superordinate systems.

System information and live demo

LHWebPlatform is a web application that runs with its database on customer (local) server hardware. Accordingly, the data is safeguarded against external access.

Machine data is never sent to Liebherr or the internet. One-click-setup makes it possible to set up the system without specialized expertise. The server only needs to be accessible from the connected machines.

The app is continuously developed and enhanced. To enable the app functionality, a license key must be provided.

Click here for a live demo of the LHWebPlatform:

Contact

Florian Schuon

Head of Digital Solutions

Liebherr-Verzahntechnik GmbH

Kaufbeurer Straße 141

87437 Kempten/Allgäu

Germany

Phone: +49 831 786 1523

umati

More information

Read interesting articles from our customer magazines and press releases