Liebherr segment clamping arbor SECLA

Clamping systems for gear manufacturing are usually very individual and have special requirements regarding concentricity and interfering contours. For this reason, it is particularly important to find the right clamping device for the application.

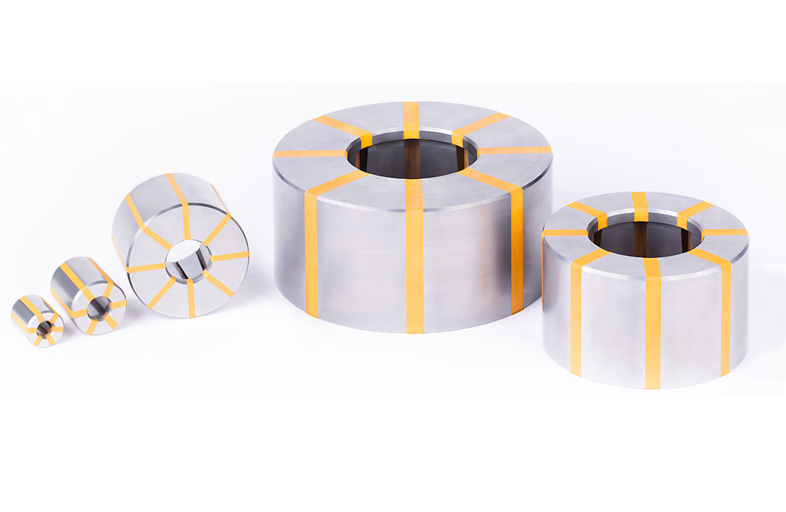

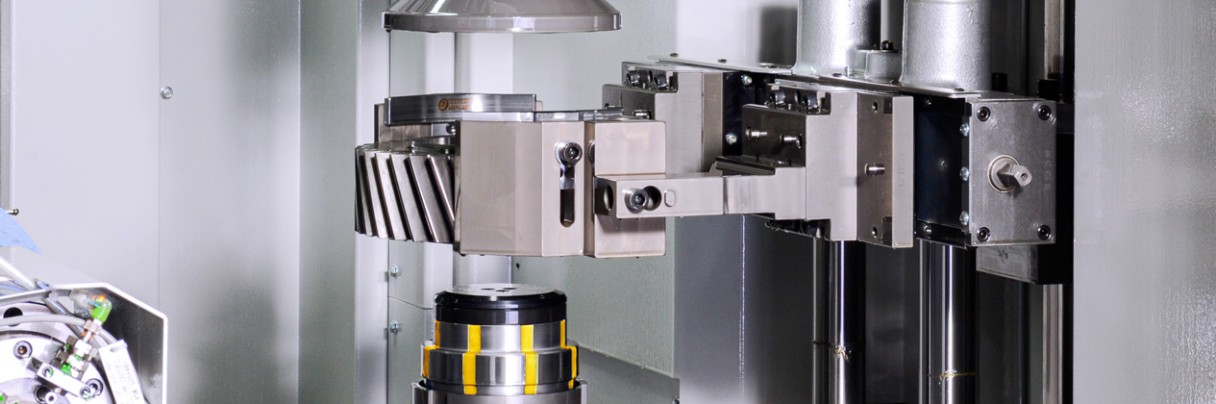

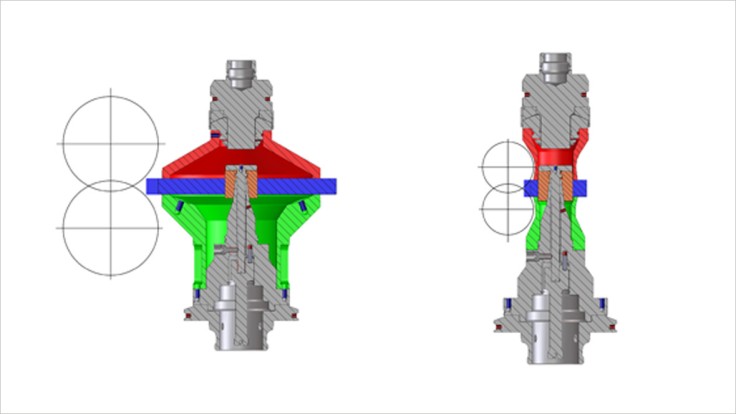

Liebherr’s segment clamping arbor SECLA is an innovative, inexpensive standard solution which will be delivered to you within just ten weeks. The clamping technology reduces expensive downtimes and is suitable for all Liebherr technologies (gear hobbing, shaping, skiving, grinding).

Video: The operating principle of our segment clamping arbor explained

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Standard segment clamping arbor

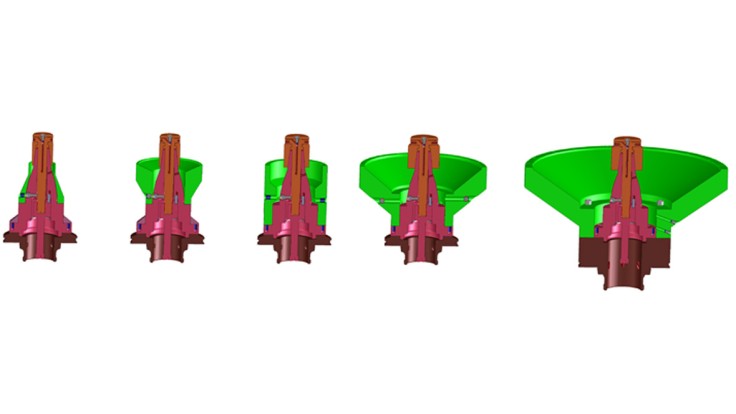

Size 1-4

Optional

- Collision and working area investigation*

- Adapter for Liebherr standard machine table interface

- Suitable grease

* may extend the delivery time

- Suitable tools

- Load handling attachment for ergonomic handling

- Test workpiece and measurement report

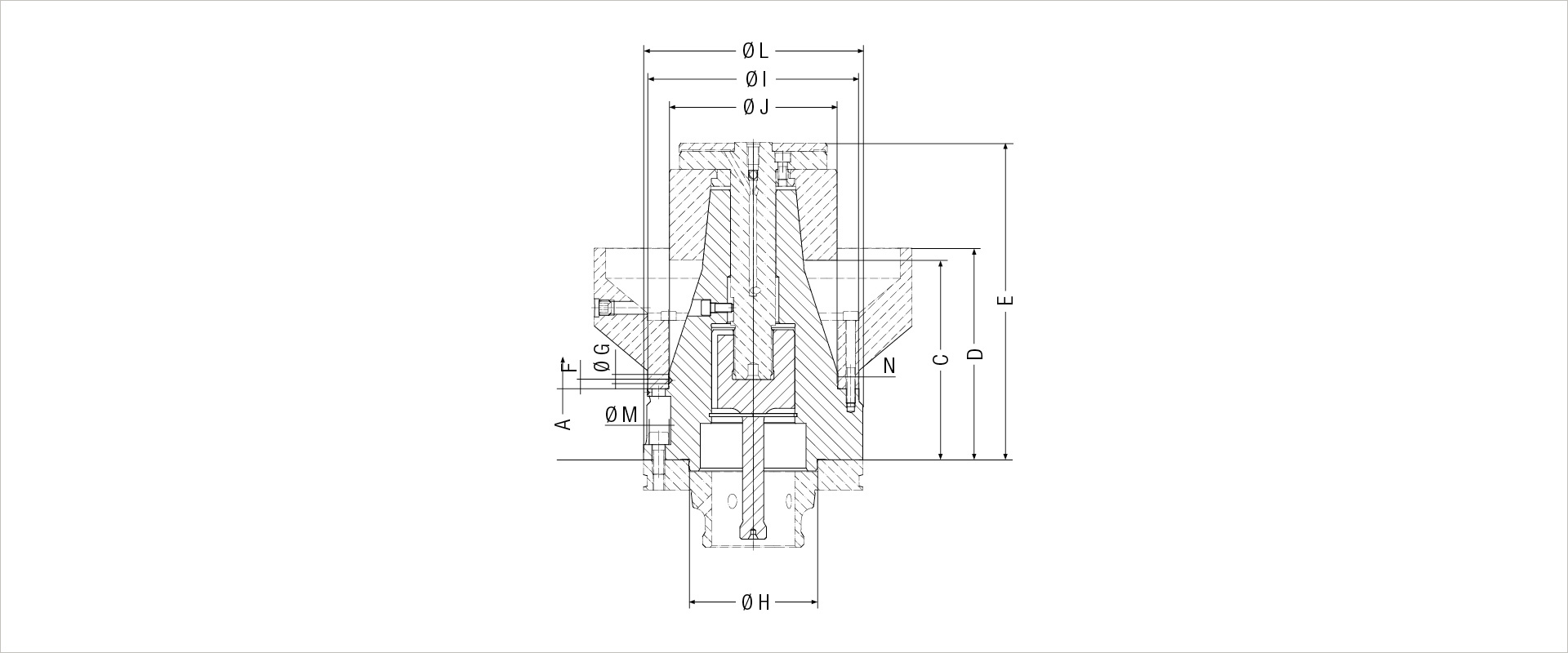

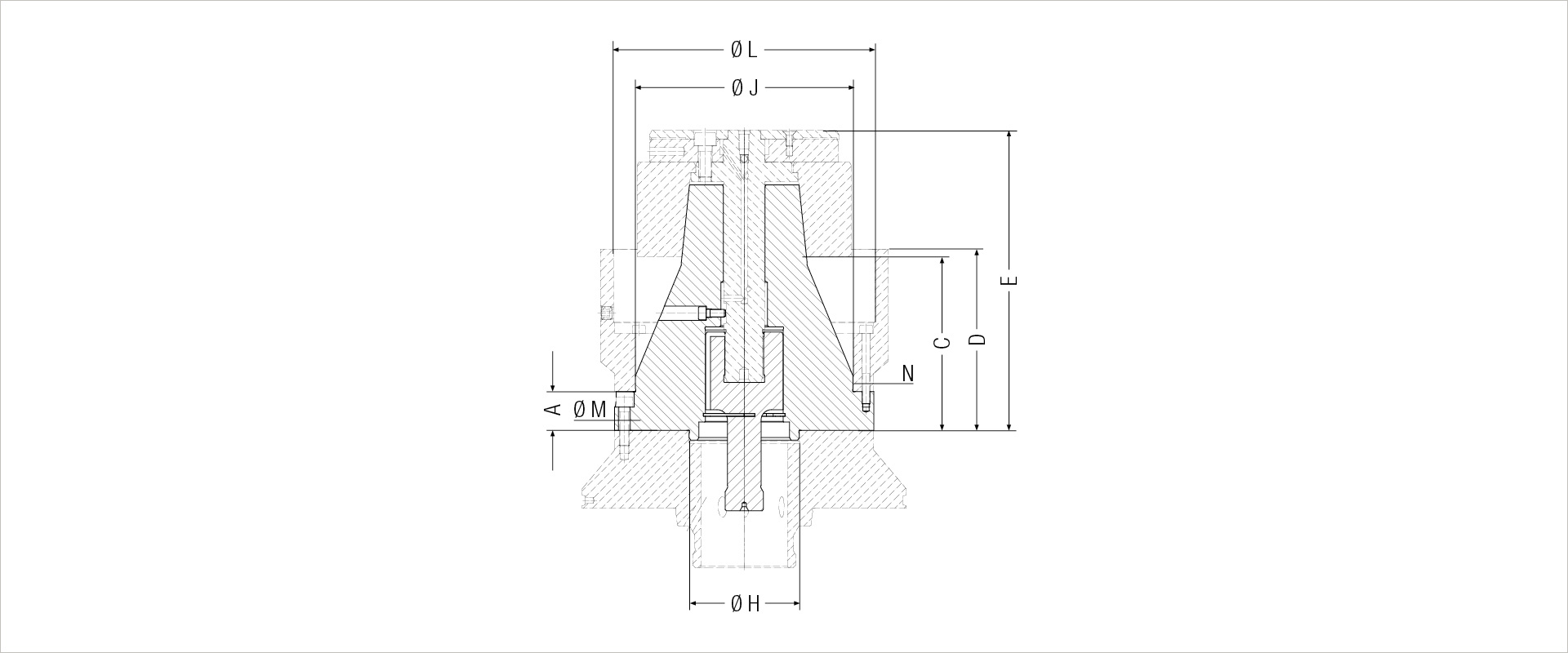

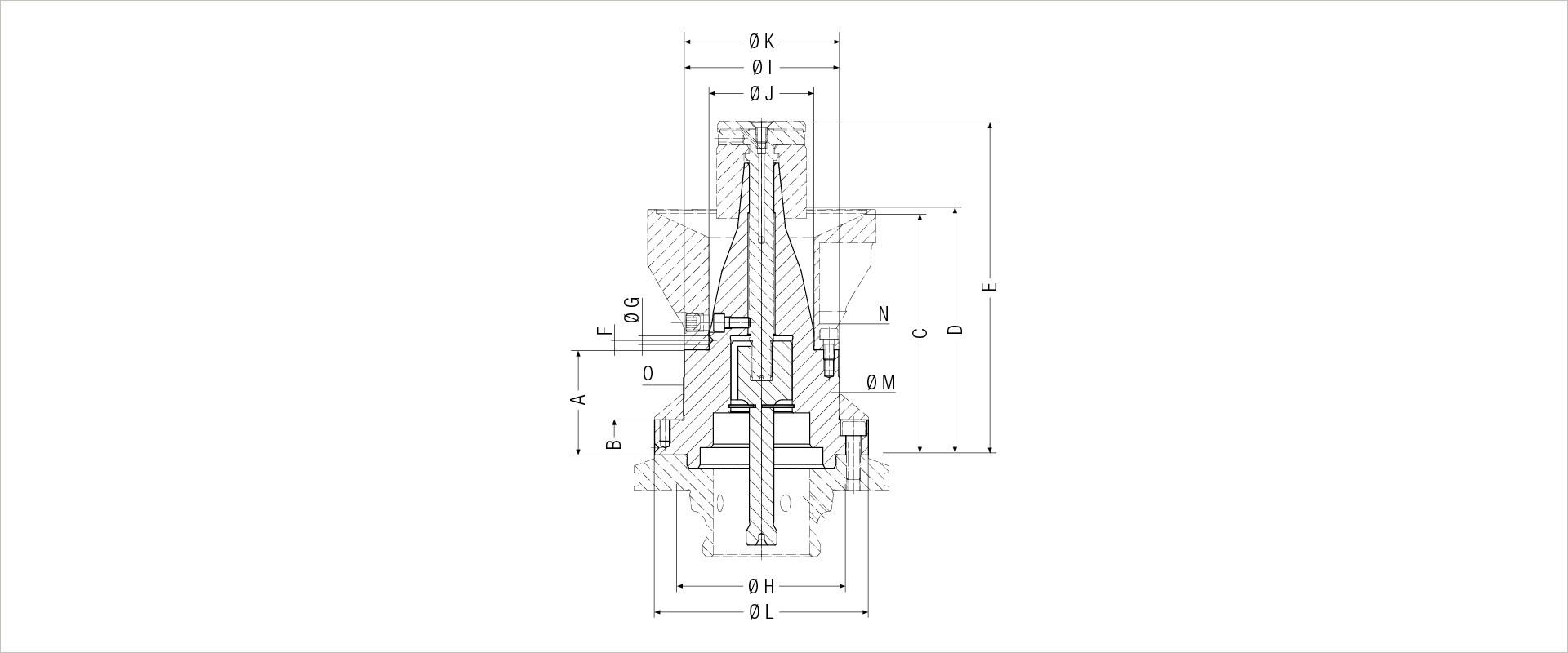

| Size | 1 | 2 | 3 | 4 | |

| Clamping range | mm | Ø 20 - Ø 32 | Ø 25 - Ø 41 | Ø 32 - Ø 51 | Ø 41 - Ø 62 |

| Radial runout | mm | < 0.008 | < 0.008 | < 0.008 | < 0.008 |

| Max. actuating force | kN | 8 | 10 | 12 | 25 |

| Clamping margin* | mm | 1.5 | 1.5 | 1.5 | 2 |

| Release stroke* | mm | 2 | 2 | 2 | 2.5 |

| Max. stroke of the clamping bushing | Ø mm | +0.2 / -0.3 | +0.3 / -0.4 | +0.3 / -0.4 | +0.4 / -0.5 |

| Permitted clamping range** | Ø mm | ± 0.05 | ± 0.1 | ± 0.1 | ± 0.2 |

| A | mm | 80 | 77 | 60 | 60 |

| B | mm | 20 | 20 | 20 | 20 |

| C* | mm | 135 | 135 | 135 | 136 |

| D | mm | 140 | 140 | 140 | 140 |

| E* | mm | 170 | 177 | 190.5 | 198.5 |

| F | mm | 5.5 | 5.5 | 5.5 | 5.5 |

| Ø G | mm | 5 | 5 | 5 | 5 |

| Ø H | mm | 85 | 85 | 85 | 85 |

| Ø I | mm | 60.5 | 69.5 | 88 | 89 |

| Ø J | mm | 32.5 f7 | 41.5 f7 | 60 f7 | 63 f7 |

| Ø K | mm | 89 f7 | 89 f7 | 89 f7 | 89 f7 |

| Ø L | mm | 122 -0.05 / -0.2 | 122 -0.05 / -0.2 | 122 -0.05 / -0.2 | 122 -0.05 / -0.2 |

| Ø M | mm | 9 | 9 | 9 | 9 |

| N | mm | M 6 | M 6 | M 6 | M 6 |

| O | mm | M 6 | M 6 | M 6 | M 6 |

| *for clamping units; mean value of clamping range in “clamped position” | **for clamping unit with nominal bore dimension with tolerance <= IT8 | ||||

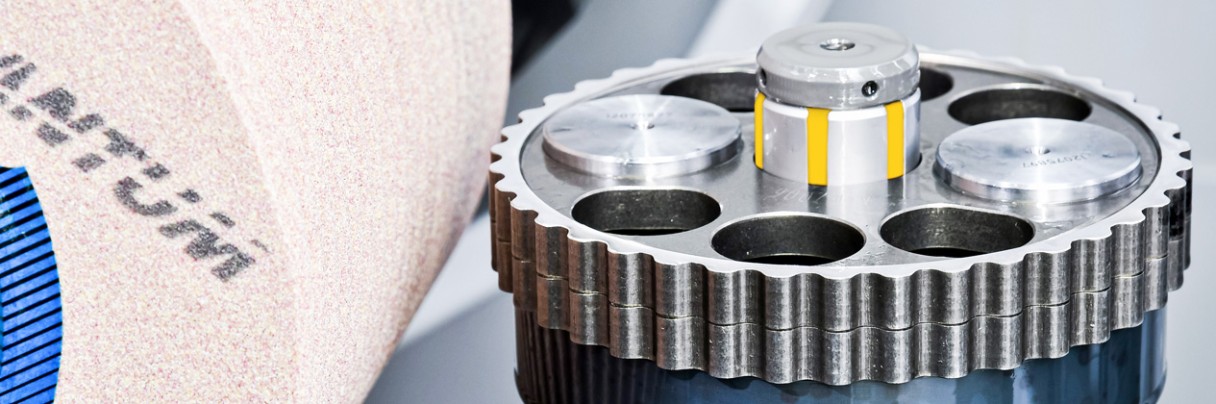

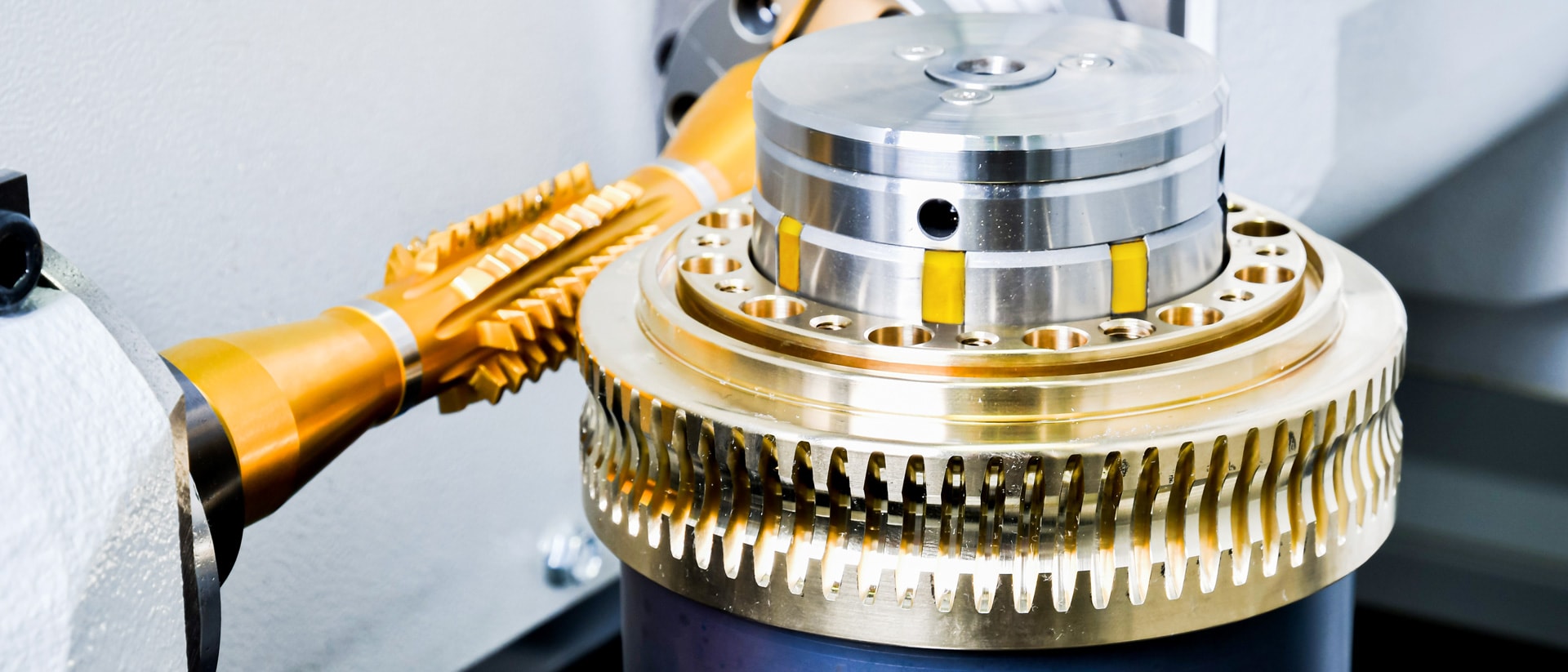

Application examples for the clamping system in gear technology

Your contact for the perfect clamping technology solution

We are happy to answer any questions about our clamping fixture.

Service for segment clamping arbor

Liebherr-Verzahntechnik GmbH

Kaufbeurer Straße 141

87437 Kempten

Germany