No such thing as can‘t

Whether it‘s a standard product or a major project, Liebherr-Verzahntechnik GmbH offers solutions for the automation of machining centers of any size. The focus is always on the benefit to the customer – whether it‘s starting out in automation, working with a large, complex system or a special solution.

Anyone familiar with Liebherr’s history knows that, of all people, its founder Hans Liebherr was not afraid to take risks. “Think for yourself, do it yourself, pay for it yourself” – that was his motto. The genesis of Liebherr pallet handling can also be traced back to this innovative spirit. When it came to looking for an automation solution for their own manufacturing system in 2008, Liebherr couldn’t find anything suitable on the market. So they quickly decided: “We’ll do it ourselves.” And so the PHS Pro pallet handling system was born – today, it is a comprehensive, freely scalable automation system with a huge scope for customer-specific adaptation for large and complex manufacturing lines.

From PHS Pro to PHS Allround

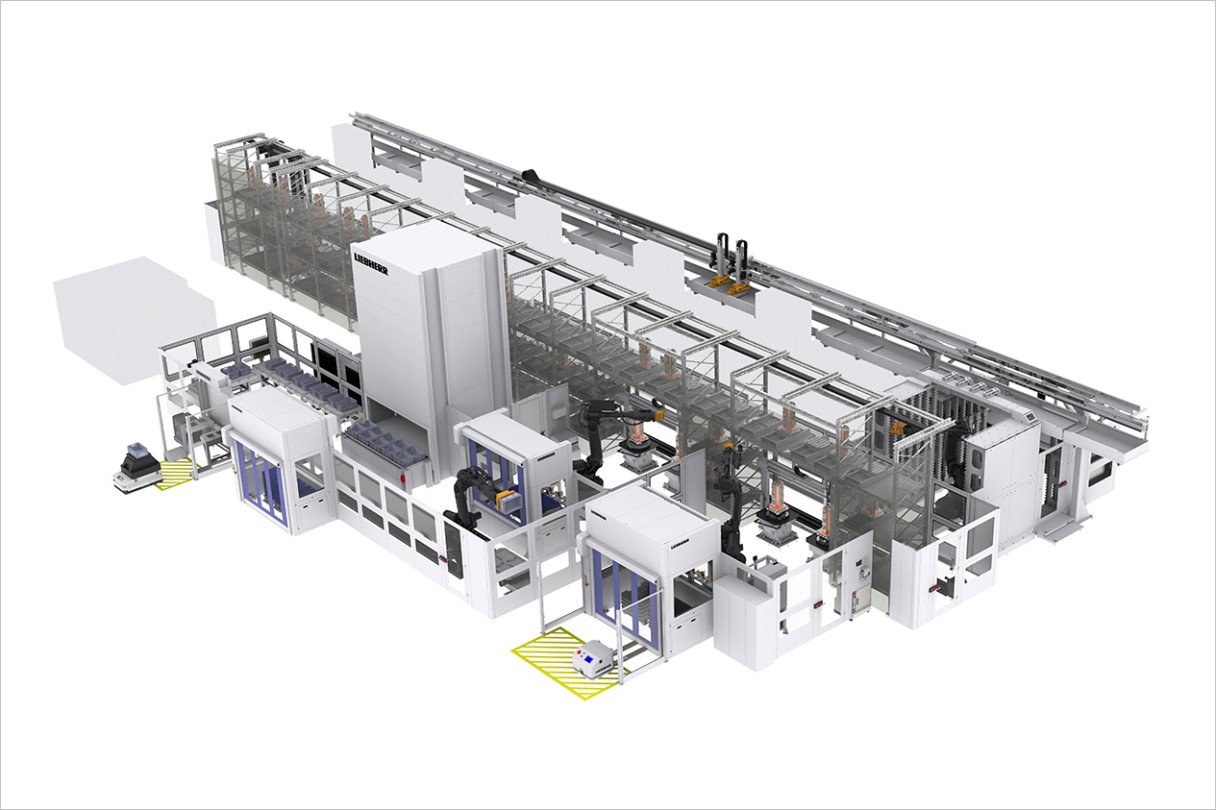

It became apparent that many companies had similar automation tasks. This was the incentive for Liebherr to develop a modular version of the PHS Pro: the PHS Allround. “The PHS Allround, with its standard components in an intelligent platform, is ideally suited to making it easier for smaller companies or automation newbies to get started – without having to compromise on functionality”, explains Agnes Schauppel, automation systems product manager. With its basic modular concept, the PHS Allround combines the advantages of a standard product with step-by-step expansion options for loading a wide variety of machines. The system is available n three different weights, with optional variants available facilitating front access, double loading or extra-long stroke, for example.

Production from a batch size of one

Pallet handling systems manipulate workpieces on uniform transport pallets. This makes them the ideal automation system for one-off and small batch manufacturing, facilitating unmanned shifts through to “lights-out manufacturing” and enabling unit costs to be reduced by up to 40 % and machine running times increased to up to 90 %. And the love of “refinement” has remained to this day. This has resulted in a wide range of possible applications and combinations, as the following three applications demonstrate.

PHS Allround automates measuring machines

The modular PHS Allround can be expanded in one-meter increments and links up to four machines. The ends of the system can also be used, allowing machines to be connected to any side of the system and – thanks to the slim telescopic fork – loaded directly. It even works in unusual applications. At a measuring system service provider in southern Germany, the PHS Allround automates a measuring machine as opposed to a machining center. Liebherr developed a special control system for connecting the measuring machine and programmed the customer-specific software interface.

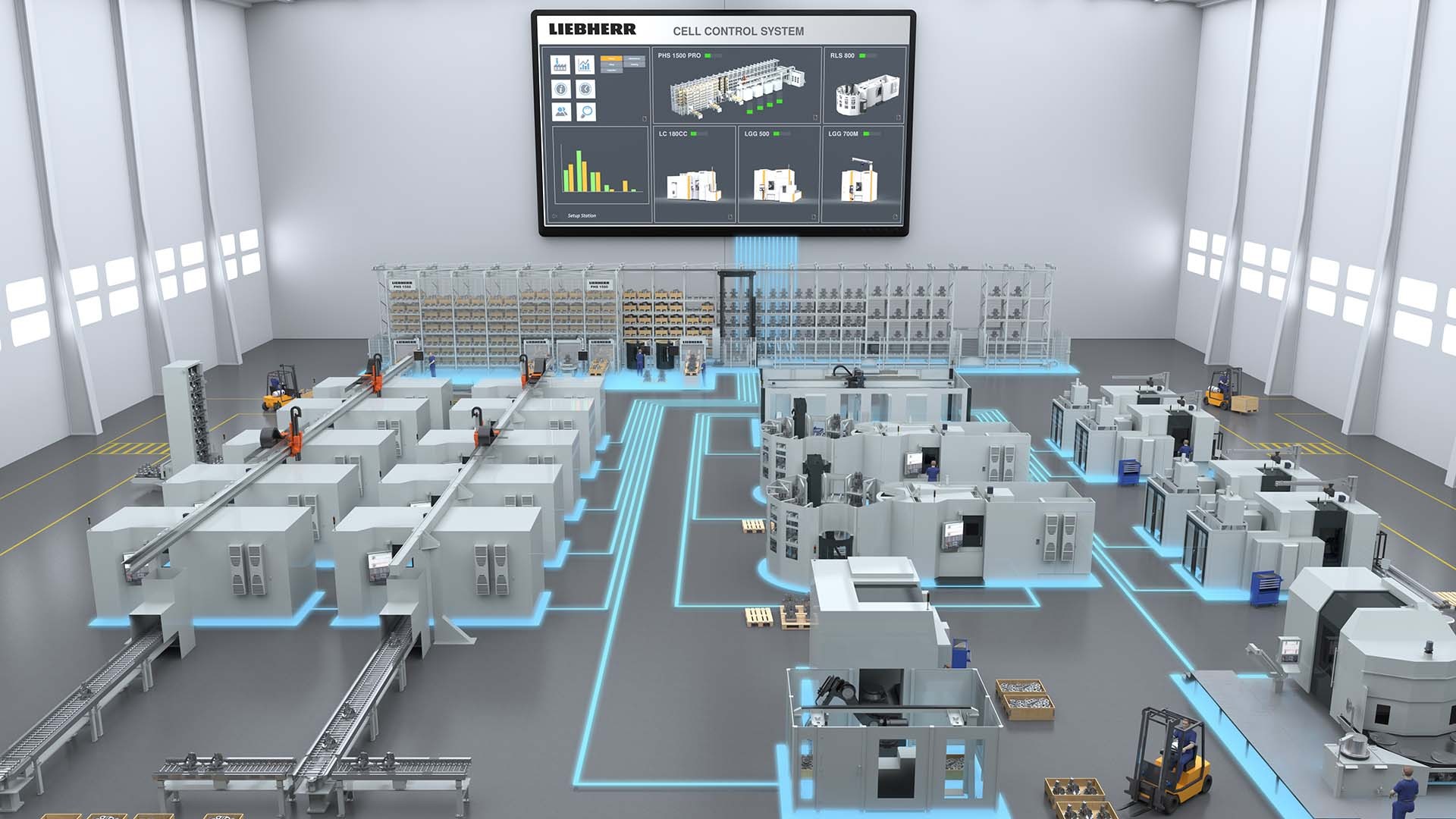

PHS Pro: fully automatic setup and machining

In 2021, Liebherr installed a PHS Pro with a high degree of automation for a manufacturing system with medium quantities and many workpiece variants at a manufacturer of components for mechanical and plant engineering. In this case, three robot cells feed workpiece blanks into the system, sort them and set them up on pallets fully automatically. The vision system used recognizes 20 different workpiece variants. The PHS then picks up the clamped parts and supplies them to the machining centers. The appropriate tools for machining are managed in a central memory and delivered to the machines by a distribution system. After machining, the workpieces are automatically clamped, cleaned and can be discharged again. An intelligent cell control system coordinates the entire material flow.

RLS: buffer storage with bin picking

At Renault’s Cléon site, Liebherr implemented a special solution with a rotary loading system (RLS) on a manufacturing line for crank shafts. In this case, a buffer store for material pallets was com?bined with a robot system for bin picking at the line entrance. The software for this (LHRobotics.Vision) also comes from Liebherr.

Advice and support are very important – even for standard products. Our strength is that we combine experience, expertise and creativity with our extensive product portfolio.

Expertise and an extensive product portfolio

Liebherr’s automation solutions are now used in many industries. PHS systems have proven their worth in the manufacturing of construction and agricultural machinery, in the aviation industry, in general mechanical engineering and in mold making. A key factor for success undoubtedly lies in selecting the right system for the specific application. “Advice and support are very important – even for standard products. Our strength is that we combine experience, expertise and creativity with our extensive product portfolio,” emphasizes Agnes Schauppel.