Compact and powerful all-rounders

Liebherr presents the new series of generating and profile grinding machines for hard machining of external and internal gears on workpieces with diameters of up to 500 millimeters. The LGG series follows the successful Liebherr LCS 300 to 500 series. With an impressive range of added features, they offer more flexibility and grinding performance with a significantly reduced footprint.

The LGG 500 and its sister models the LGG 300, LGG 380 and the manual solution LGG 700 M are Liebherr’s new series to succeed the LCS 300 to 500 generating and profile grinding machines that have been popular all over the world. The machines are suitable for generating grinding, profile grinding and both processes combined. The new series also retains essential features such as maximum precision, robust machine design and high flexibility. Corundum and CBN tools are available, the latter from Liebherr’s own production. The high level of performance and versatility now also extends to hard machining of internal gears: changing from external to internal profile grinding is possible in less than 30 minutes. There are also newly developed grinding heads and even more machine options.

A fully equipped grinding machine for external and internal gears with immense grinding performance as well as an automation system – that’s a very versatile combination and pretty unique in the market.

New features: slim design and higher grinding performance

On the outside, the first thing that catches the eye is the machine’s new, compact monolith design. With the footprint reduced by a third, the work area is just as big as the one of the previous model, ensuring maximum ease of use even with manual loading. With an axial travel range of up to 1,000 millimeters, the machine column allows the machining of long shafts, for example for commercial vehicles.

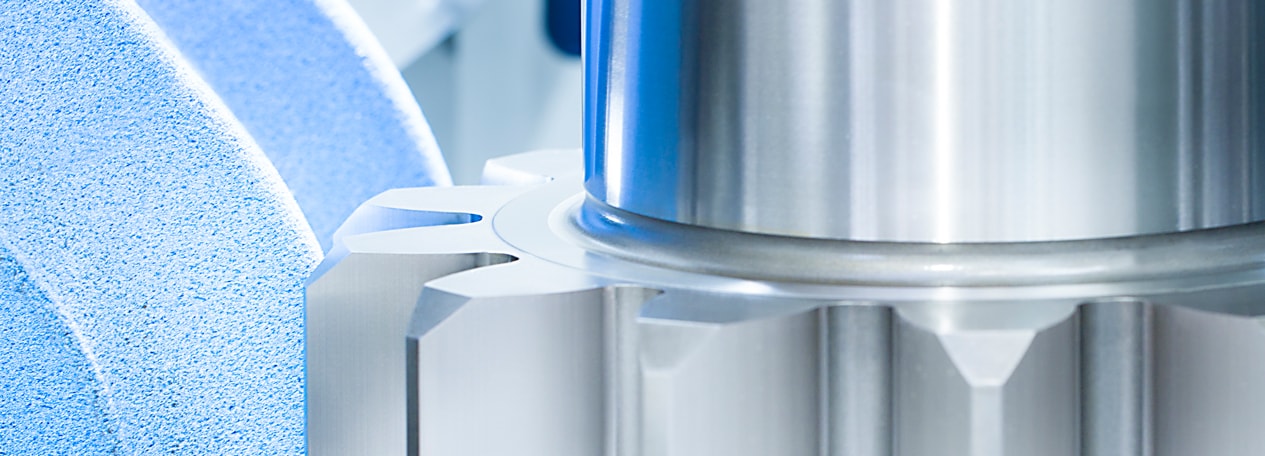

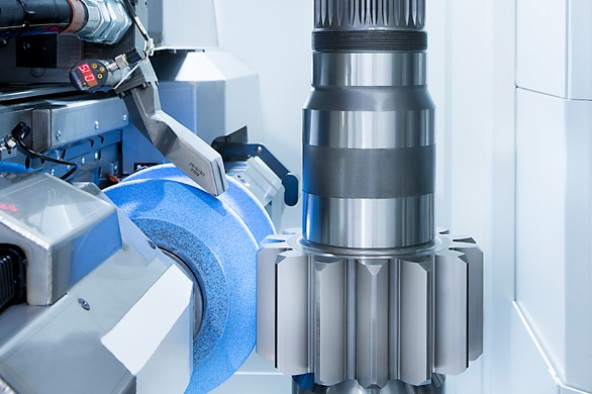

Three different directly driven grinding heads with optimized rigidity are available for the new series, and can be configured precisely as the customer requires. The grinding heads have a large effective speed range, which allows the use of large and small grinding worms at optimal cutting speed. Liebherr is a pioneer when it comes to machining collision gears with dressable and dressing-free grinding worms: the compact counter bearing ensures the highest grinding and polishing quality for critical components. Optionally, the grinding heads can be equipped or retrofitted with an auxiliary spindle or an internal grinding arm (find more information about the auxiliary spindle here).

Universal concept

LGG 500 – Maximum flexibility with regard to:

- Geometry: internal or external gears with an expanded range of workpieces

- Technology: generating or profile grinding for external gears or profile grinding for internal gears

- Batch sizes: from prototypes or small series up to large series with integrated automation system

The most powerful grinding head, the GH 320 CB, can easily handle generating grinding jobs up to module 14. Grinding worms with a volume of up to 320 millimeters in diameter and 250 millimeters in length are used. Cutting speeds of up to 80 meters per second achieve high grinding performance for dimensionally critical components at much shorter grinding times, especially for workpieces with long face widths.

Flexibility and open structures

The selection of direct drive tables is tailored to the specific component range with regard to the component weight (up to 100 kilo grams), required machining speed and optimum pitch quality. The robustly built table allows speeds of up to 2,000 revolutions per minute for generating grinding and highly accurate positioning for profile grinding.

The new LGG machine generation offers the best possible compatibility with the available clamping fixtures, so that the existing equipment can be used or inexpensively modified. The Liebherr OpenConnect concept allows GDE data to be imported and exported which, together with the gear check integrated in the machine, ensures short setup times for heavy components (find more information about LHOpenConnect here).

One platform – plenty of options

“With the new generation of machines, the customer is not buying a specialist machine, but an all-rounder that embodies maximum flexibility combined with optimum grinding performance and quality,” explains Martin Schwarzmann, Product Manager for Gear Cutting Machines at Liebherr. “A fully equipped grinding machine for external and internal gears with immense grinding performance as well as an automation system – that’s a very versatile combination and pretty unique in the market.”

The machine offers flexibility for small and medium batch sizes. With its integrated ringloader automation system and configurable Liebherr storage systems, it creates a unique basis for highly efficient large-scale production, for example of complete planetary gears, including ring gears. The huge scope of possibilities allows companies, and in particular small businesses, to carry out a wider range of processing so that they can respond much more flexibly to future market requirements.

Before its official market launch this year, the LGG 500 had already gone through an intensive, highly demanding test phase: several prototypes have already been successfully used at Liebherr and are continuously being improved.

Highlights of the LGG 500

Highlights of the LGG 500

- Small footprint: 30 percent space saving

- Large work area: large grinding stroke and machine column with 1,000 millimeters travel range

- Choice of three grinding heads: Grinding performance: up to module 14, grinding worm volume: up to 320 x 250 millimeters, grinding speed: up to 80 meters per second

- Table: workpieces up to 500 millimeters diameter, up to 100 kilograms weight, speeds up to 2,000 revolutions per minute

- Uniform interfaces: upward and downward compatibility

- Integrated automation system: flexible loading of workpieces up to 100 kilograms

- Peripherals: individual storage solutions

- Optional: swivel-out tailstock on the counter column, measuring probe for integrated gear check, auxiliary spindle