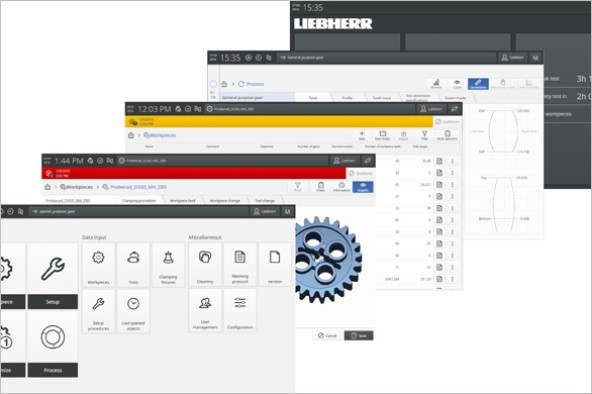

When Peter Pruschek, Head of Electronic and Control System Development at Liebherr-Verzahntechnik GmbH, presents the new LHGearTec control system, he first highlights the striking new features: “We are entering the market with a 24 inch touchscreen monitor – an above-average size for machine tools. The monitor is flanked by an additional number pad for fast numeric input because we have learnt that inputting data on a touch basis is not suitable for workshop applications. Moreover, the control panel is supplemented by a removable handheld unit with a second touchscreen display, the LHMobile. The handheld unit – the first of its kind in this form – is an integral part of machine operation.”

Not only does it simply mirror the view of the large screen, there are also operator functions and displays between the fixed main screen and the removable handheld unit. “The LHGearTec display on the main screen guides the user through the programming and set-up procedures. The LHStation offers the operator the present handling functions that are currently required, while the large screen provides more clarity and further details and data.”