Group

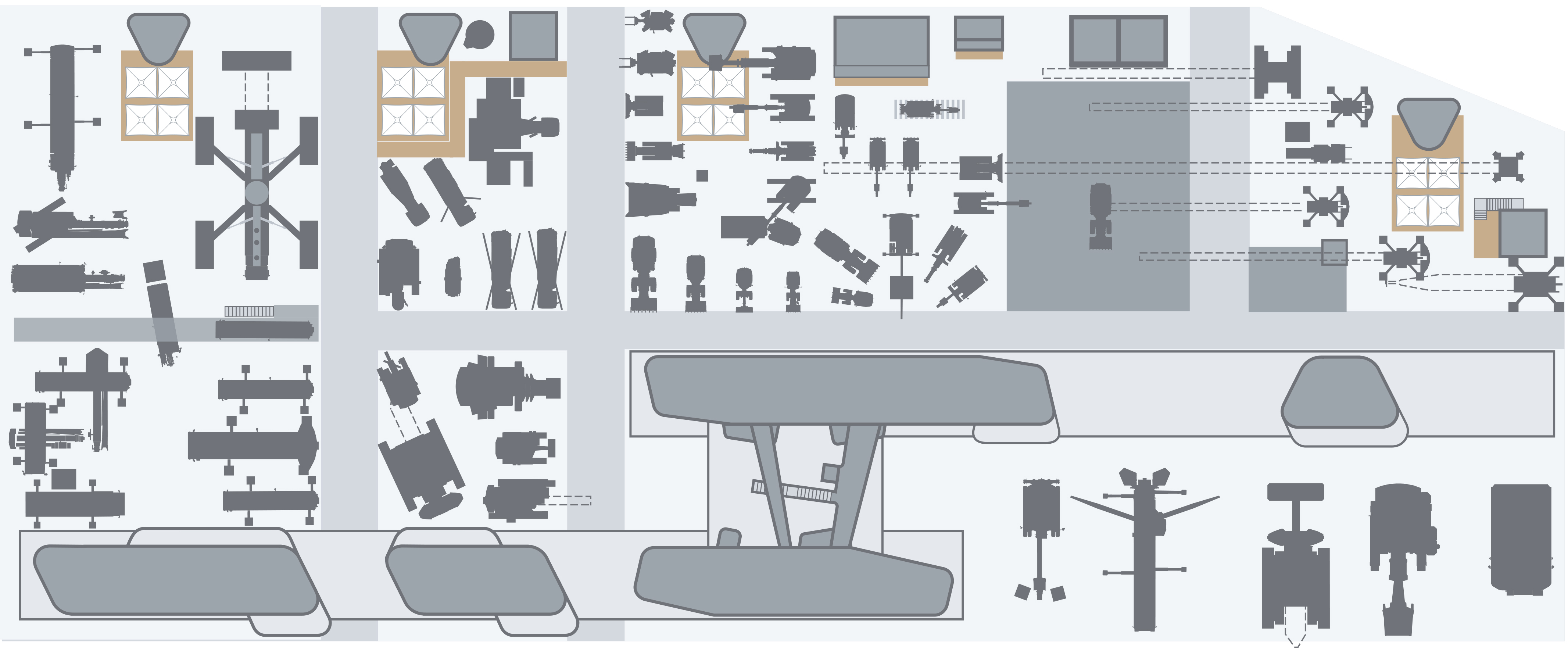

GroupMachines and solutions that inspire

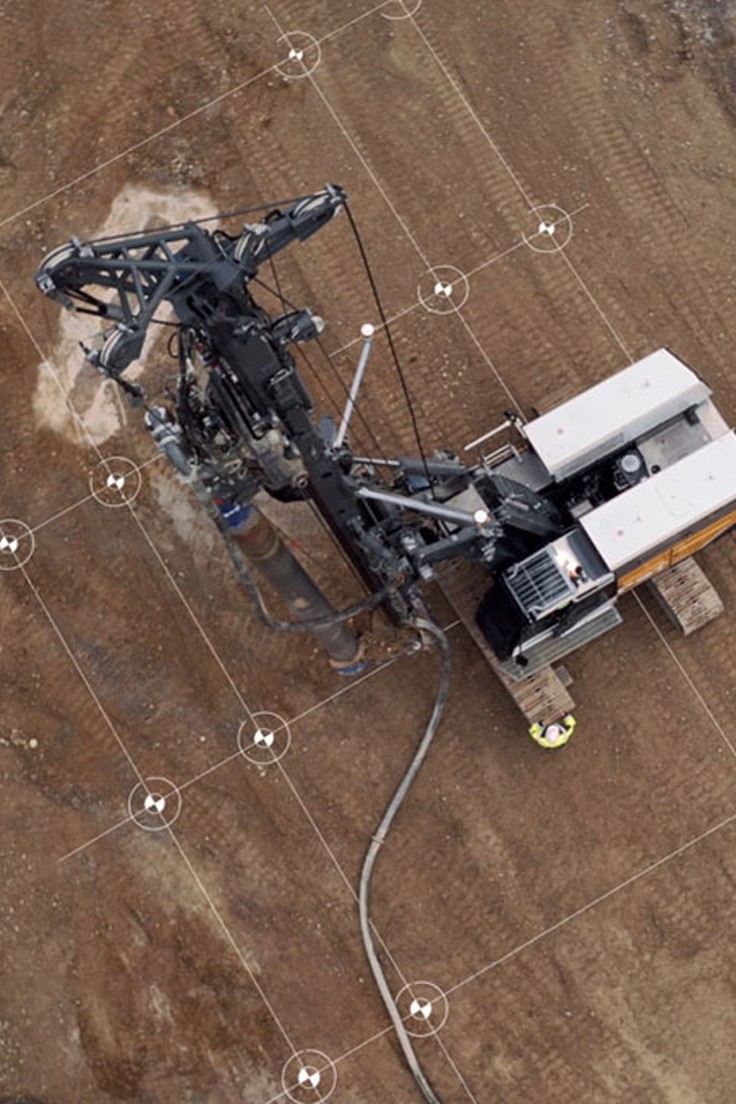

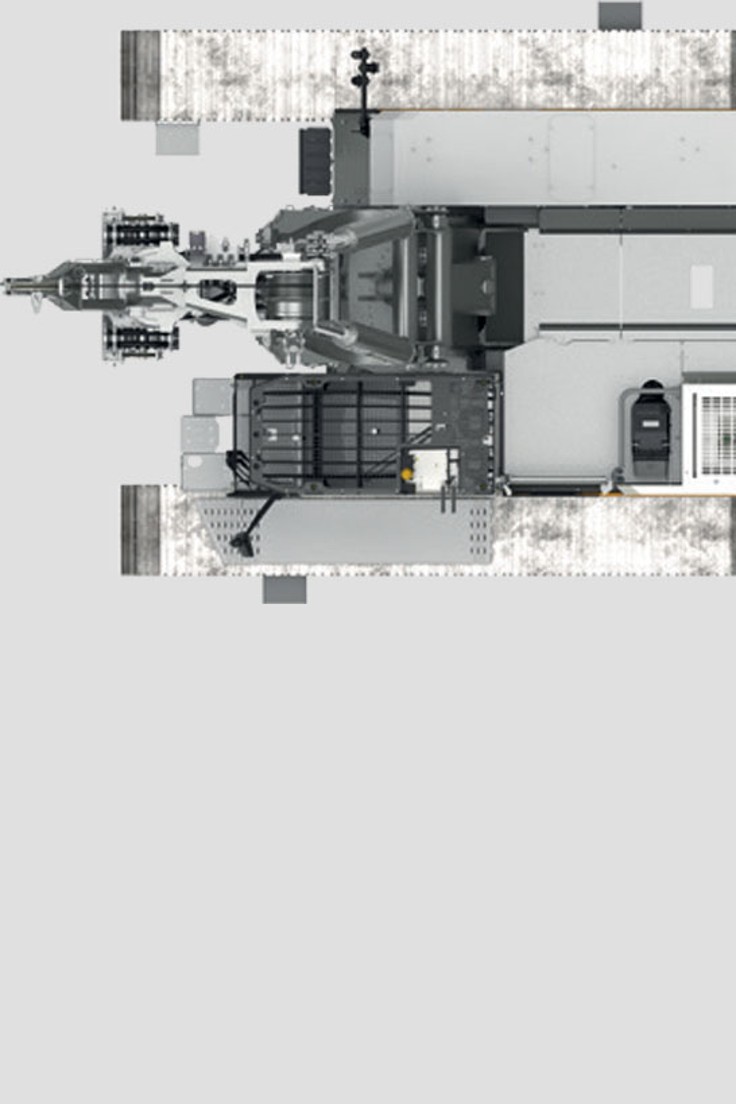

Deep foundation

Liebherr-Werk Nenzing GmbH has an extensive portfolio of innovative solutions: deep foundation machines, powerful duty cycle crawler cranes for material handling and crawler cranes with lifting capacities of up to 400 tonnes. The product range is complemented by future-oriented digital solutions and tailored customer services – perfectly matched to the requirements of modern building sites.

Deep foundation

*This audio guide is spoken by an AI voice.

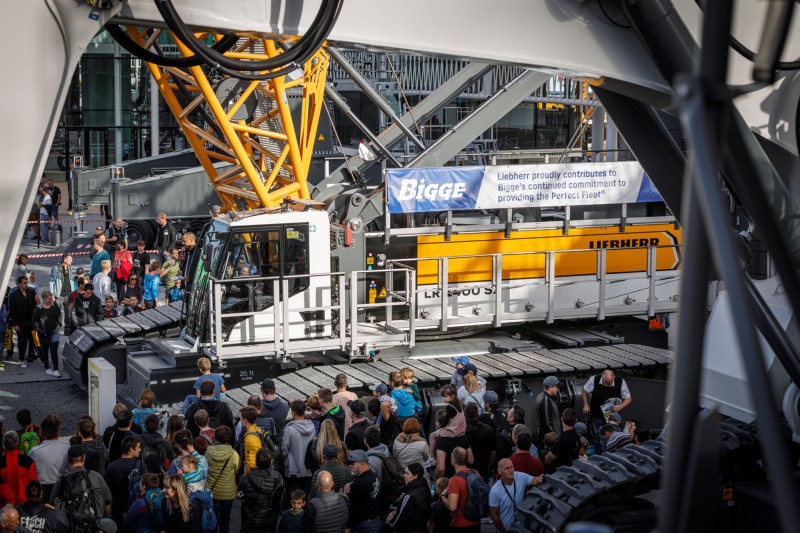

Images from Bauma 2022

Digital solutions and services for deep foundation work

Modern IoT solutions and services optimise human-machine interaction, simplifying the construction sites of the future. These include planning tools and analytical instruments for construction site management, assistance systems for the operator and remote maintenance tools for service technicians.

Digital solutions and services for material handling

IoT solutions and services of the latest generation optimise the human-machine interaction. These include analytical software, assistance systems to support the operator as well as remote maintenance tools for service technicians. Material handling processes become faster, more ecological and more cost-effective.

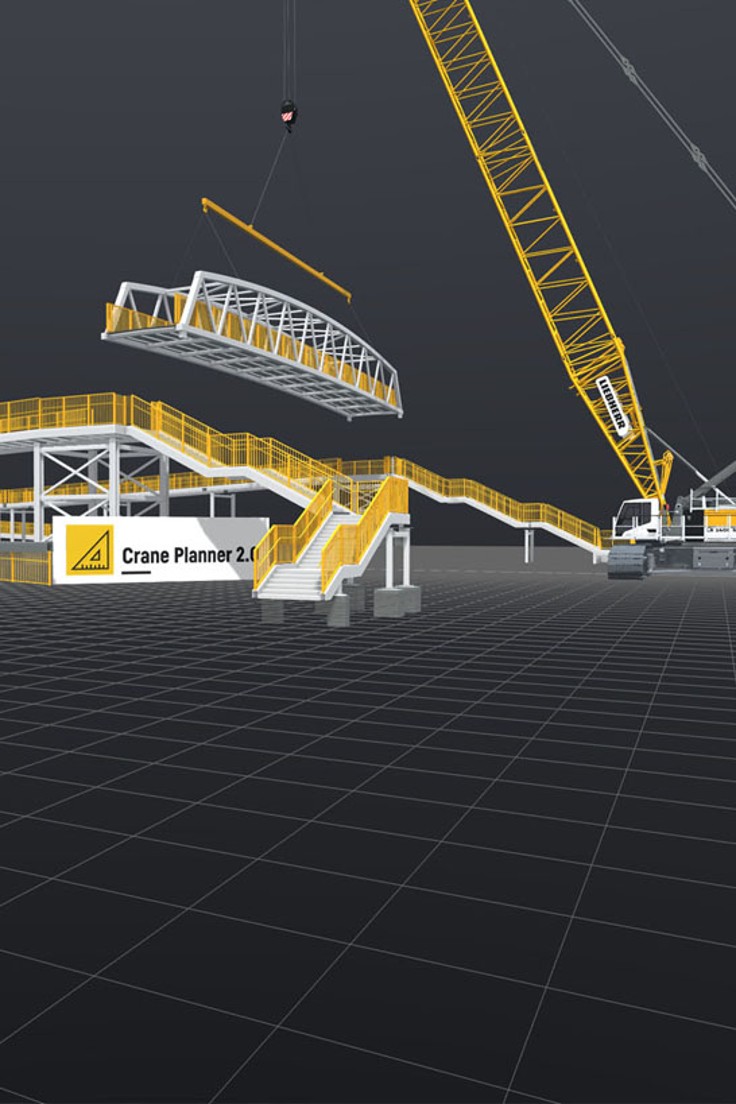

Digital solutions and services for lifting

Modern IoT solutions and services are revolutionising the interaction between people, machines and environment, making construction sites fit for the future. These include tools for planning within construction site management, assistance systems for operating machines and remote maintenance solutions for service technicians.