Components

ComponentsWater content determination Litronic-WMS II

Water cut meter / Analyzer

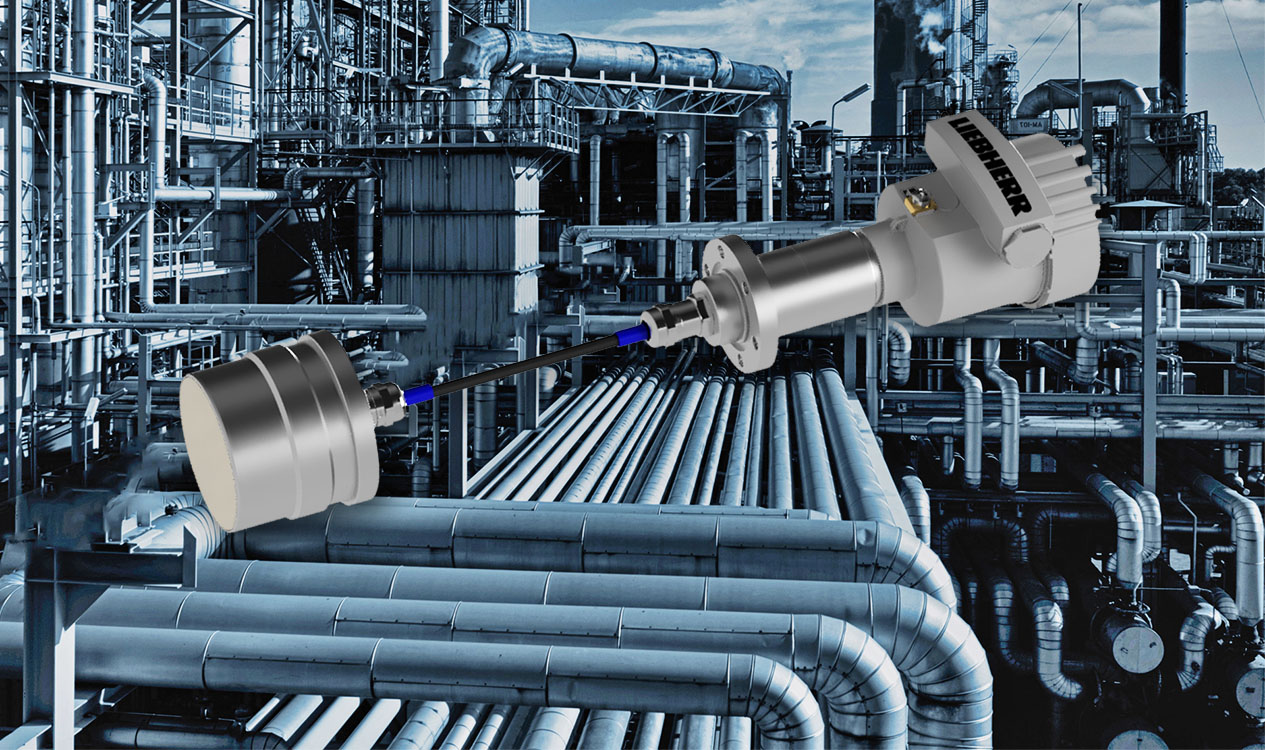

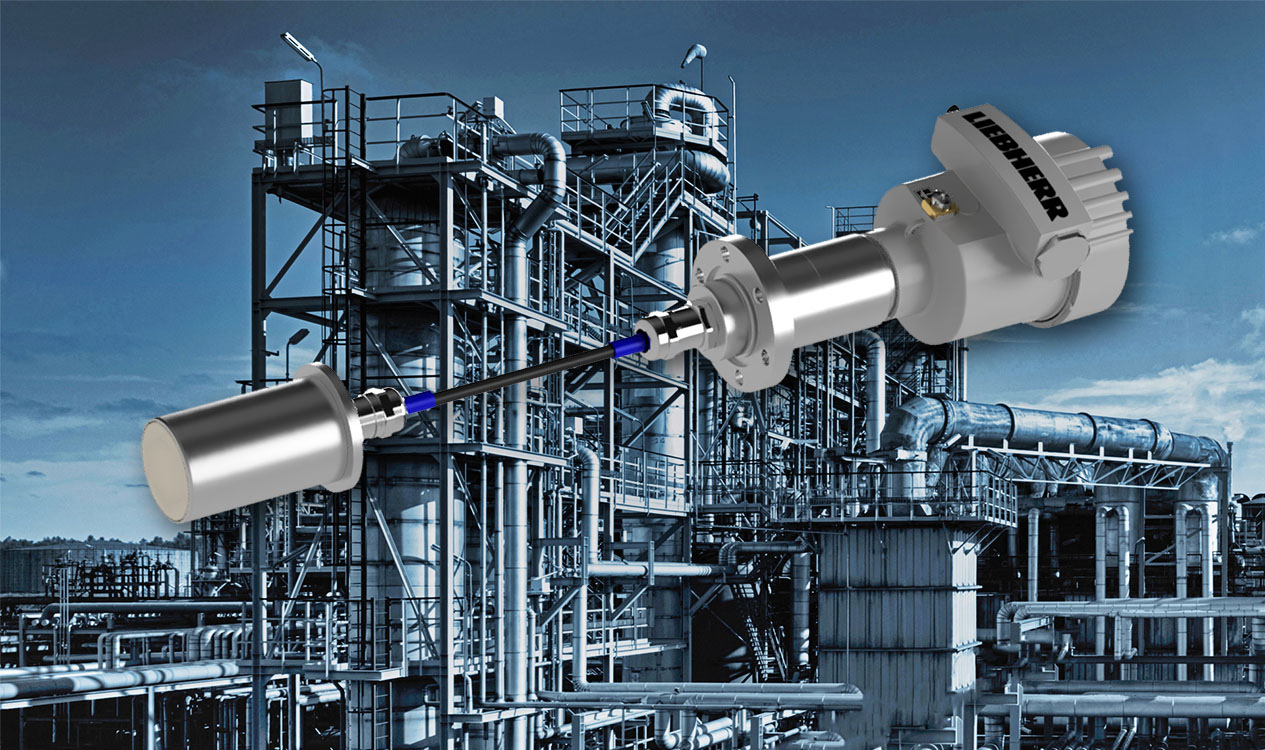

Liebherr sensors in use in explosive areas

The Liebherr Litronic-WMS II water content meter is used to measure the moisture or water content of a wide range of water content of a wide variety of media and materials in refineries, on oil platforms, in pipelines, in tanks, in many applications in the chemical and petrochemical industry, sludge dewatering, drying, waste incineration and sewage treatment plants. Also in the agricultural sector up to the pharmaceutical industry and many other industries.

The wide range of applications extends from the most diverse emulsions to the finest powders and dusts and coarse-grained materials (max. grain size 32 mm) such as

- Oil, crude oil, diesel, biodiesel, hardening oil (upstream / downstream)

- Coolants

- Paints, lacquers, solvents

- Wax, resin

- Other emulsions, suspensions

- Water-product separation

- Dust, slag

- Fertiliser

- Washing powder, agent

- Sawdust

- Biomass

- Flour

- etc.

Applications:

- Water cut meter

- Pipeline, tanks BS&W (Basic sediment and water) measurement

- Petroleum purification/desalination

- Automatic well testing

- LACT units

- Separation control

The stand-alone and precise measuring device for water content/moisture determination in the running process guarantees the highest quality and safety in EX-protected production environments, the further processing and refinement of very many emulsions and bulk materials.

The software enables fast and accurate calibration of the measured sections.

Liebherr offers sensors for the following device protection categories:

Certificates

ATEX / UKEX:

EU-type examination certificate number: EPS 21 ATEX 1 140 X / EPS 22 UKEX 1 159 X

DIN EN IEC 60079-0:2018, EN 60079-1:2014, EN 60079-11:2012, EN 60079-26:2015, EN 60079-31:2014

Gas EX-protection:

II 1/2 G Ex db/ia IIC T4 Ga/Gb

Dust EX-protection:

II 1/2 D Ex tb/ia IIIC T135°C Da/Db

IECEx:

Certificate number: IECEx EPS 21.0047X

IEC 60079-0:2017 Edition: 7.0, IEC 60079-1:2014-06 Edition: 7.0,

IEC 60079-11:2011 Edition: 6.0, IEC 60079-26:2014-10 Edition: 3.0,

IEC 60079-31:2013 Edition: 2

Gas EX-protection:

Ex db/ia IIC T4 Ga/Gb

Dust EX-protection:

Ex tb/ia IIIC T135°C Da/Db

The WMS II sensors are permitted for the following markets:

In addition to their high precision and robustness, the measuring devices from Bad Schussenried are characterised by their reproducibility.

Once the system has been calibrated, further measuring points can be set up or devices renewed on this basis at any time without great effort. The plant thus always remains reliable, regardless of its previous term and age.

Water Cut Meter Analyzer- Litronic-WMS II

This video is provided by Google*. When you load this video, your data, including your IP address, is transmitted to Google, and may be stored and processed by Google, also for its own purposes, outside the EU or the EEA and thus in a third country, in particular in the USA**. We have no influence on further data processing by Google.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

| Suitable for use in potentially explosive areas | Dust/Gas - Zone 0/20 |

| Measurement | |

| Physical principle | Capacity determination in the high frequency stray field |

| Adjustable measuring range | 0 - 100 % moisture content (measuring window adjustable) |

| Update cycle | 65 ms |

| Temperature measurement accuracy | ± 0.5 °C |

| Outflow | |

| Measured value transmission - Sensor display content | Current loop with “4 - 20 mA” for external display (option) |

| Measured value transmission - sensor PLC or main computer | Analogue: “4 - 20 mA” active at 500 Ohm digital: Hart Modem |

| Valid measurement | 3.75 mA to 21.6 mA (NAMUR) |

| Interface signal resolution | 16 bit |

| Max. length of connecting cable | 1000 m (depending on cable) |

| Power supply | |

| Connection | Un = 12 V DC (SELV/PELV) |

| Temperature | |

| Medium temperature | -5 °C* to 80 °C |

| Ambient temperature sensor head | 5 °C to 80 °C |

| Ambient temperature transmitter head | 5 °C to 70 °C |

| Storage temperature | -25 °C to 80 °C |

| * Under certain conditions | |

| Pressure | |

| Pressure | -1 bar up to 75 bar |

| Material | |

| Housing / rod material | 1.4571 (AISI 316TI) Optional: 2.4819, Hastelloy®C-276, Alloy C-276 |

| Transmitter head material | Die-cast aluminium, copper content of max. 0,1 % |

| Measuring field material/wearing protection | PEEK |

| Dimensions | |

| Housing W/H/D | 88 mm 160 mm 143 mm |

| Rod diameter | 45 mm |

| Rod length | 6" to 32" (further lengths on request) |

| Measuring field material | PEEK |

| Measuring field position | Front or side |

| Suitable for use in potentially explosive areas | Dust/Gas - Zone 0/20 |

| Measurement | |

| Physical principle | Capacity determination in the high frequency stray field |

| Adjustable measuring range | 0 - 100 % moisture content (measuring window adjustable) |

| Update cycle | 65 ms |

| Temperature measurement accuracy | ± 0.5 °C |

| Outflow | |

| Measured value transmission - Sensor display content | Current loop with 4 - 20 mA for external display (option) |

| Measured value transmission - sensor PLC or main computer | Analogue: 4 - 20 mA active at 500 Ohm digital: Hart Modem |

| Valid measurement | 3.75 mA to 21.6 mA (NAMUR) |

| Interface signal resolution | 16 bit |

| Max. length of connecting cable | 1000 m (depending on cable) |

| Power supply | |

| Connection | Un = 12 V DC (SELV/PELV) |

| Temperature | |

| Medium temperature | -5 °C* to 80 °C |

| Ambient temperature sensor head | 5 °C to 80 °C |

| Ambient temperature transmitter head | 5 °C to 70 °C |

| Storage temperature | -25 °C to 80 °C |

| * Under certain conditions | |

| Pressure | |

| Pressure | -1 bar to 75 bar |

| Material | |

| Housing material | 1.4571 (AISI 316TI) Optional: 2.4819, Hastelloy®C-276, Alloy C-276 |

| Measuring field material/wearing protection | PEEK |

| Dimensions | |

| Sensor W/H | 45 mm 112.6 mm |

| Housing transmitter head | 88 mm / 160 mm / 143 mm |

| Cable length between sensor and transmitter head | 10 m |

| Suitable for use in potentially explosive areas | Dust/Gas - Zone 0/20 |

| Measurement | |

| Physical principle | Capacity determination in the high frequency stray field |

| Adjustable measuring range | 0 - 100 % moisture content (measuring window adjustable) |

| Temperature measurement accuracy | ± 0.5 °C |

| Outflow | |

| Measured value transmission - Sensor display content | Current loop with 4 - 20 mA for external display (option) |

| Measured value transmission - sensor PLC or main computer | Analogue: 4 - 20 mA active at 500 Ohm digital: Hart Modem, Modbus RTU |

| Valid measurement | 3.75 mA to 21.6 mA (NAMUR) |

| Interface signal resolution | 16 bit |

| Max. length of connecting cable | 1000 m (depending on cable) |

| Power supply | |

| Connection | Un = 12 V DC (SELV/PELV) |

| Temperature | |

| Medium temperature | -5 °C* to 80 °C |

| Ambient temperature sensor head | 5 °C to 80 °C |

| Ambient temperature transmitter head | 5 °C to 70 °C |

| Storage temperature | -25 °C to 80 °C |

| * Under certain conditions | |

| Pressure | |

| Pressure | Flange for bolting on: -1 bar to 1 bar Flange for welding on: -1 bar to 16 bar |

| Material | |

| Housing material | 1.4571 (AISI 316TI) Optional: 2.4819, Hastelloy®C-276, Alloy C-276 |

| Measuring field material/wearing protection | Ceramic, Al2O3ZrO2 |

| Dimensions | |

| Sensor | 78 mm |

| Housing transmitter head W/H/D | 88 mm 160 mm 143 mm |

| Cable length between sensor and transmitter head | 10 m |

- Indirect measuring method: Capacity determination in the high frequency stray field. This method uses the different dielectric constant (permittivity) of water and different materials (solids and liquids)

- Fully reproducible sensors: If the plant is subsequently extended with sensors or if sensors are replaced, no recalibration is necessary thanks to the built-in microprocessor.

- Process control and regulation: Thanks to extensive interfaces, the water content measurement can be integrated into process control systems and controls.

- Cost saving: Time-consuming and costly laboratory analyses are no longer necessary or can be reduced.

- Temperature measurement/temperature compensation: The sensor can also be used to determine the temperature of the medium.

- Limit values: Maximum or minimum limits can be set using the software. Light or sound signals can be triggered if required.

- Mean value calculator: The sensor passes on already averaged values to the evaluation and transfer module.

- Compressive strength: The rod sensor withstands process pressures of up to 75 bar.

- Sliding fitting: For cleaning, flushing or sensor replacement, the sliding fitting can be easily pulled out of the pipeline even under these circumstances without disturbing the process.

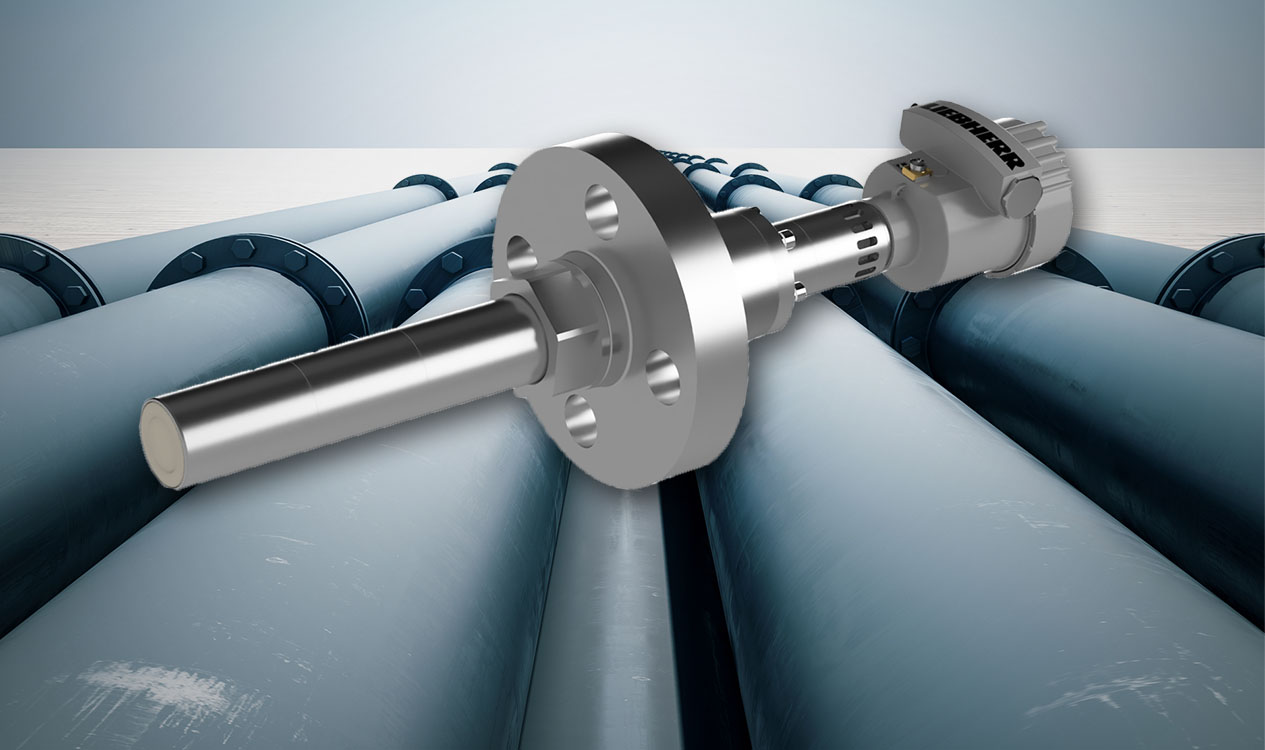

- Flange: Use the flange to connect the sensor to the pipeline, tank system or bulk solid receptacle

- Sliding fitting: With the sliding fitting you can mount the sensor on tank systems (rod sensor) and pipelines. The sliding fitting allows the sensor to be changed quickly without having to empty and depressurise the tank or the pipe.

- External display and control unit: The display and control unit is mounted up to 50 m away from the sensor in an easily accessible position. It is connected directly to the electronics of the sensor and powered by it.

- Software: for start-up and configuration.