Annual Report 2021

Gear technology and automation systems

Turnover in the gear technology and automation systems product segment amounted to € 210 million in 2021, representing a € 3 million or 1.4 % decrease compared to the previous year.

Strong growth in the Americas

Compared to the previous year, there was a slight increase in order intake and sales across the German machine tool industry. According to the German Machine Tool Builders’ Association (VDW), however, turnover was still well below pre-crisis levels. The Liebherr gear technology and automation systems product segment performed below the trend, with turnover slightly below the previous year’s level.

The product segment experienced uneven performance across the various regions. In the European Union, turnover dropped due to losses in Germany and France. The non-EU countries grew due to increases in Turkey and Russia. Performance was particularly strong throughout the Americas, with heavy growth in the USA, Brazil and Mexico. Turnover in Asia and Oceania fell due to a strong downturn in China.

In terms of the individual product areas, turnover was up in gear cutting machines, tools and contract manufacturing, whereas automation systems saw a decline, due mainly to sluggish spending throughout the automotive industry.

Liebherr is a technology partner with expertise across the entire range of manufacturing processes. This allows us to develop solutions for special challenges.

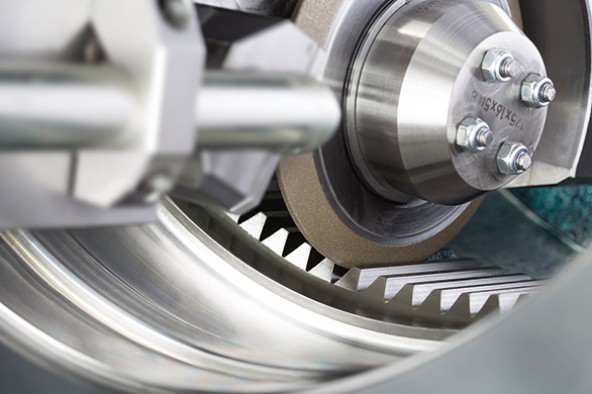

A changing mobility market offers potential for the future

Liebherr unveiled a number of gear technology and automation systems innovations in 2021. Mobility was a major focus. Electromobility in particular offers great potential for gearing technologies, due to its heavy reliance on internal gears, which places high demands on machining quality. To cater to those demands, Liebherr developed and released a number of e-gear solutions last year. In the generating grinding product area, Liebherr unveiled innovative new CBN profile grinding wheels in the small diameter range, which offer customers many advantages. The new products offer high process reliability, making them attractive for many new applications, including in the aviation industry.

There were also breakthroughs in the development of solutions for battery pack assembly in the automation product area. Liebherr is now in a position to offer the essential processes for battery pack assembly. There are plans for further expansion in this area, as well as optimisations in the automated installation of long cables.

Another milestone was the opening of the new Tech Centre in Kempten (Germany), which allows for processes to be tested under real conditions. The new facility offers partial assembly lines with technology modules for the automatic production of battery packs (including screwing, plugging, gripping and positioning).

For 2022, Liebherr expects an increase in sales in the gear technology and automation systems product segment. The consequences of the war in Ukraine must also be taken into account, however, which are difficult to assess at the present time.