Accuracy at its best

Accurate positioning and precise execution of piling or drilling processes are crucial for the success of deep foundation machines. Using latest satellite navigation technology, Liebherr’s positioning system LIPOS assists the driver in aligning attachments and tools precisely. The compiled data of the piling or drilling processes can be stored for quality assurance and project reporting.

LIPOS video

Demonstration clip of the LIPOS positioning system for accurate alignment of deep foundation machines at the jobsite.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Fully integrated in existing IT solutions

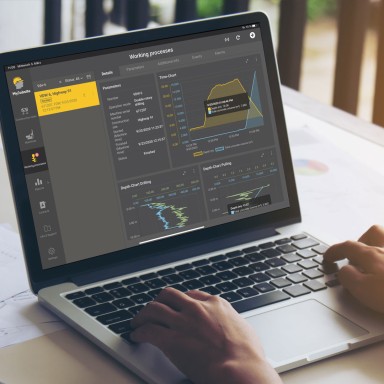

The construction site of the future is going digital. Modern software solutions simplify the processes on the jobsite, streamline documentation efforts and faciltate the interactions between operator and machine.

Video: MyJobsite with LIPOS and PDE

Precise positioning (LIPOS), data recording and transmission (PDE), central data management and analysis (MyJobsite) are all topical issues on the digital construction site.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).YOUR BENEFITS

Precision

Pinpoint precision of the drilling and piling work.

Simplicity

The machine operator can quickly select and drive to all piling and drilling points.

Time and cost savings

No pegging out or continuous re-measuring required.

Higher safety

Fewer personnel in the direct vicinity of the machine while positioning.

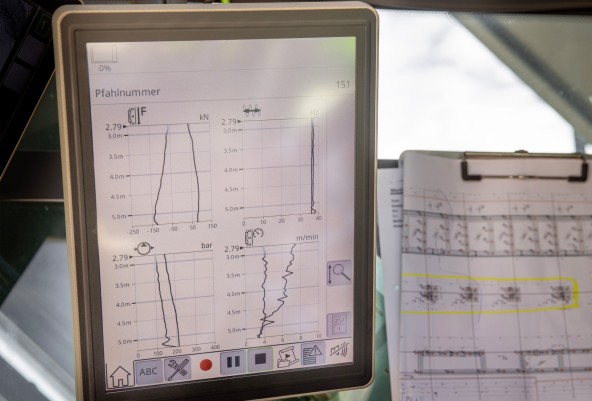

Consistent data recording

Recording of the drilling points and work processes through the process data recording system PDE.

Quality assurance

Automatic transmission of the data to MyJobsite for visualisation and analysis.

Monitoring

Monitoring the progress of the construction site with real-time information.

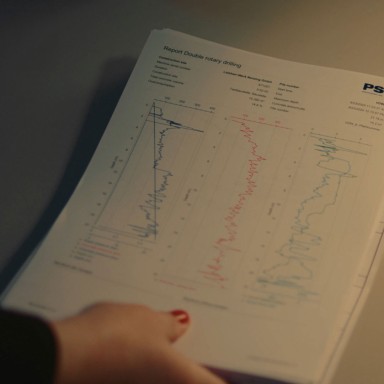

Reporting

Generation of comprehensive and informative jobsite reports.

Get in touch

If you have any further questions, please contact our local sales or service team: