WHICH BEARING DESIGNS ARE AVAILABLE?

Depending on the type of wind turbine, triple-row roller bearings, double-row tapered roller bearings or single-row tapered roller bearings are used as main bearings. While the roller bearing leads to lower stresses in the adjacent construction, the double-row tapered roller bearing is particularly attractive because it has zero play, therefore allowing for an optimal rolling behaviour of the bearing.

The single-row tapered roller bearings ensure optimum rolling characteristics and ideal force distribution by the layout and design. In addition, the precise rolling elements combined with the narrow manufacturing tolerances of the two single-row tapered roller bearings provide for an exact preloading in the installed condition.

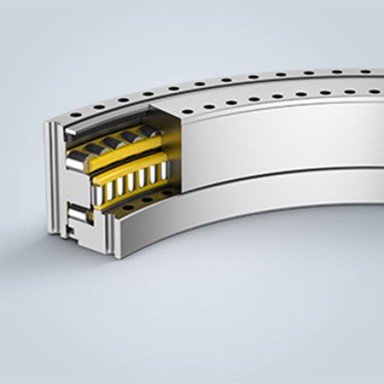

Triple-row roller bearings

Lower tension in the adjacent construction

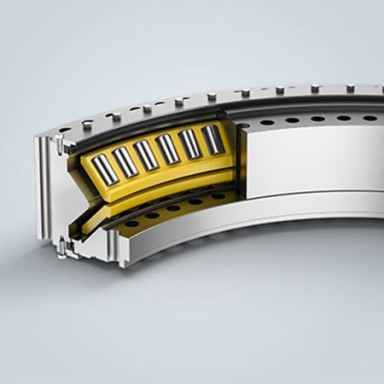

Double-row tapered roller bearing

Bearing with zero play and optimal rolling behaviour of the rolling elements

Single-row tapered roller bearing

Main bearing consists of the front and rear bearing

Get in touch

Contact our local sales team or follow us on our LinkedIn channel.