Top-level technology

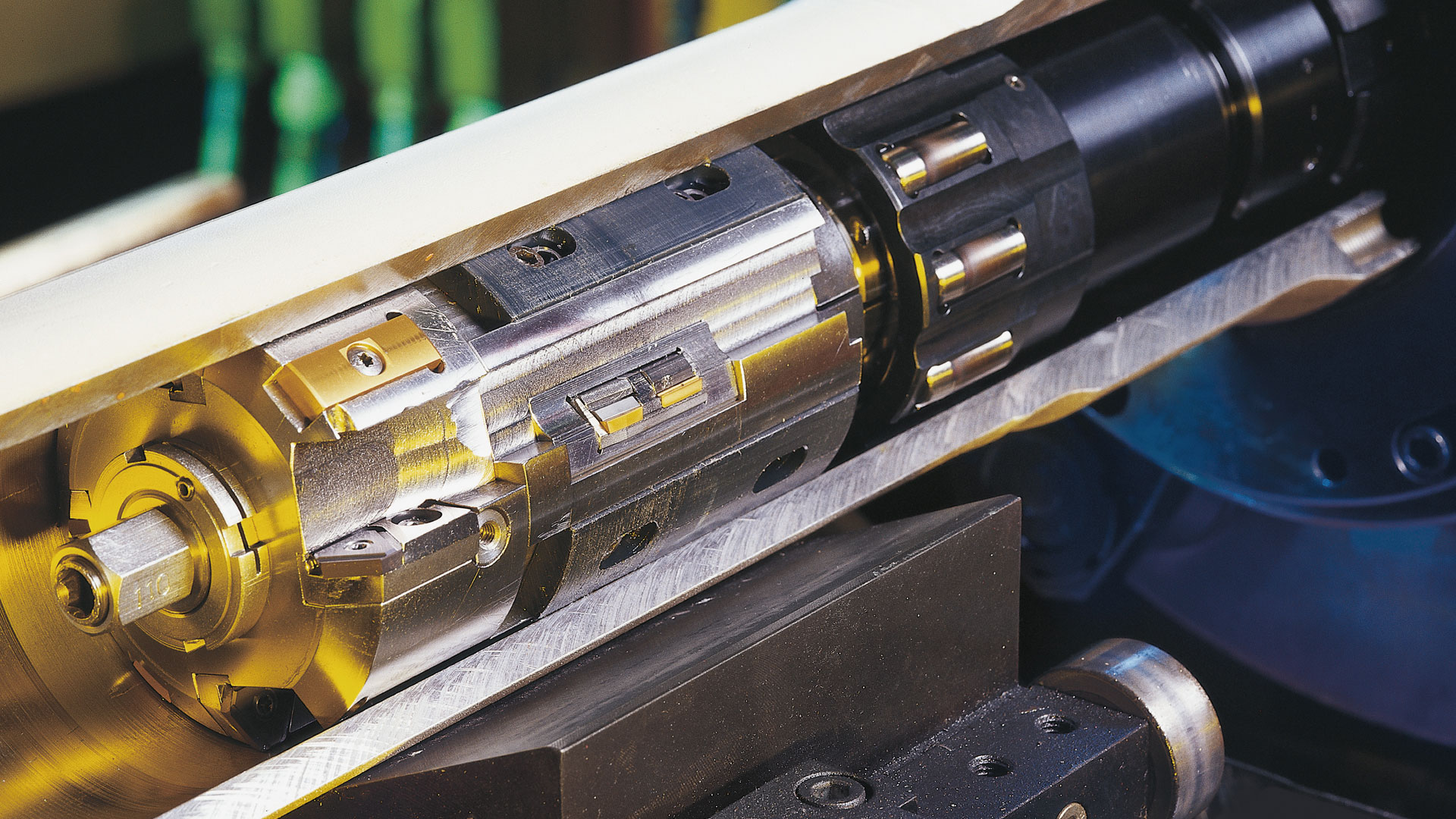

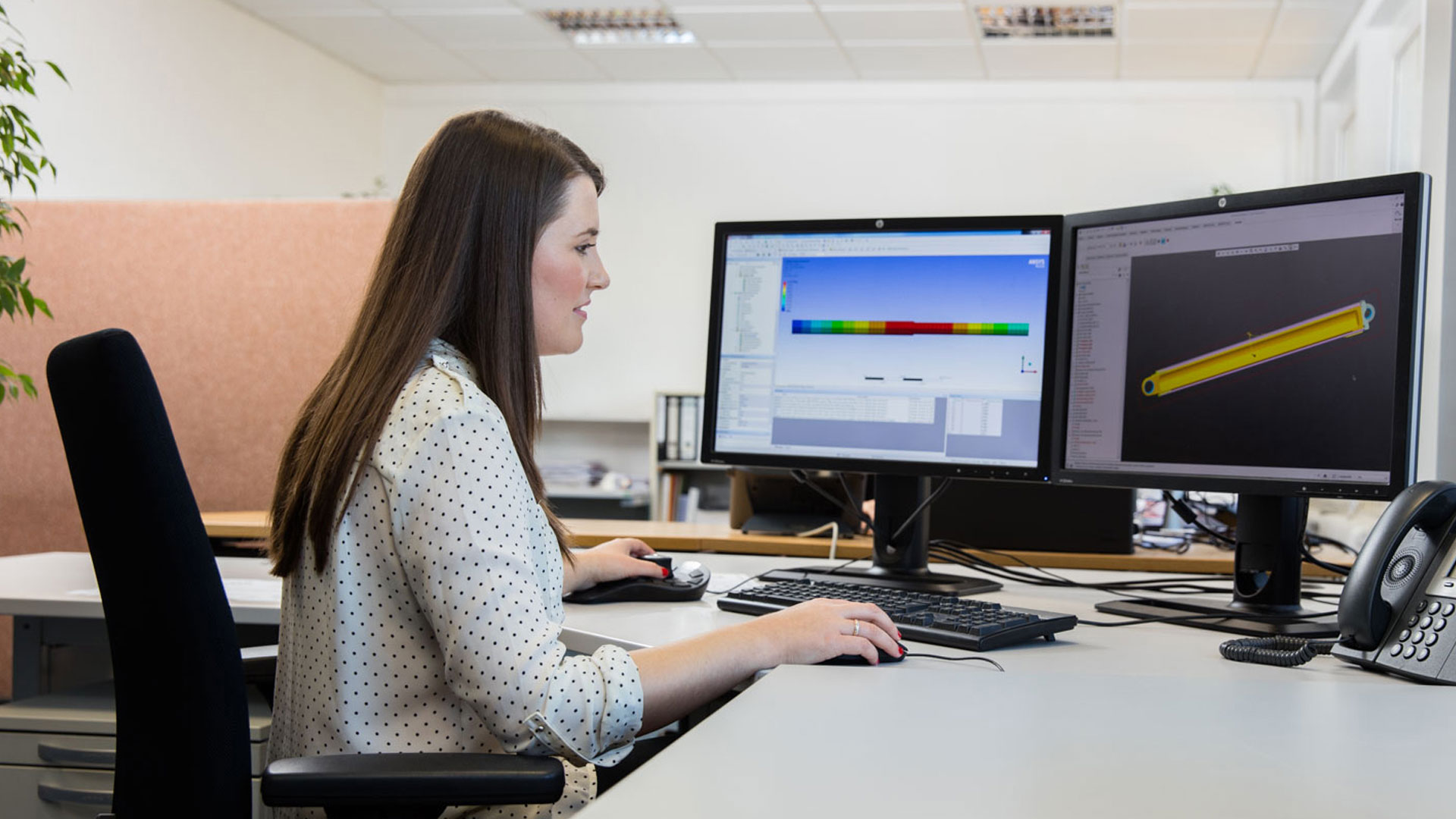

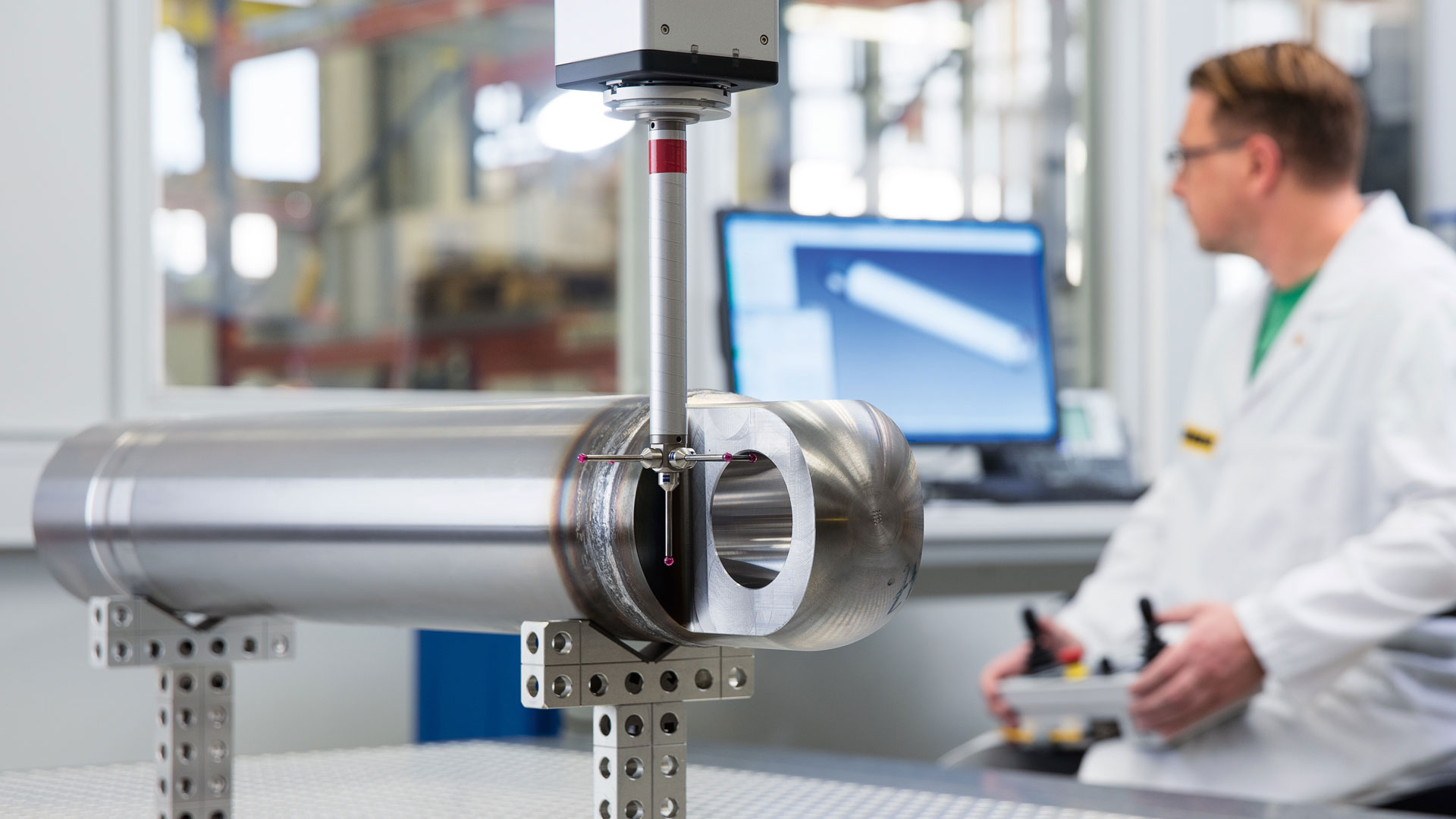

With their extensive expertise, our engineers lay the foundations for ensuring that Liebherr components meet the highest quality requirements. Up-to-date computational procedures, innovative technologies and modern machine tools guarantee the transition of design into production that corresponds to the latest state-of-the-art and at the same time, is also tailored to specific cases of use.