State-of-the-art test solutions for your electronics

In the competence centre for electronics in Lindau, Liebherr operates a Test Center with state-of-the-art testing and measurement technology that realistically simulates environmental influences.

Overview of our services

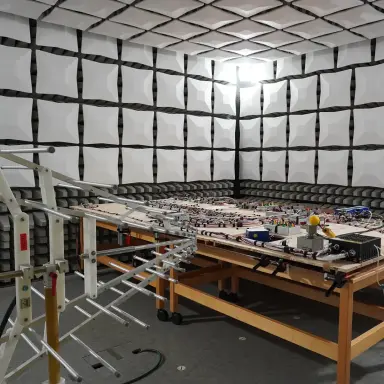

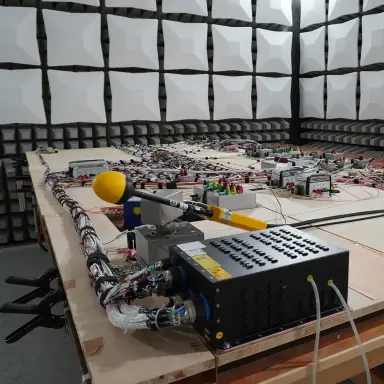

Electromagnetic compatibility

Our Test Center examines electromagnetic compatibility (EMC) for you in accordance with all common standards in the aviation, automotive, railway and commercial industry sectors.

Vibration and shock testing

The Liebherr test laboratory has two electrodynamic vibration test systems at your disposal, which you can use both for development purposes and for certifications.

Environmental tests

In the following tests we simulate different environmental influences:

- Climate Tests

- Thermal Shock Tests

- Corrosion Tests

- HALT Tests

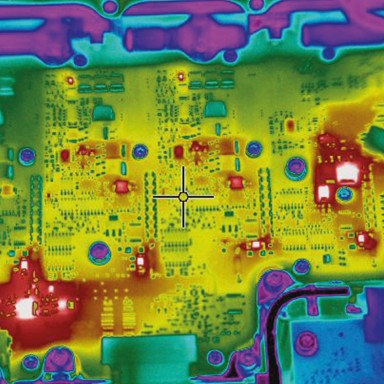

- Infrared Thermal Analysis

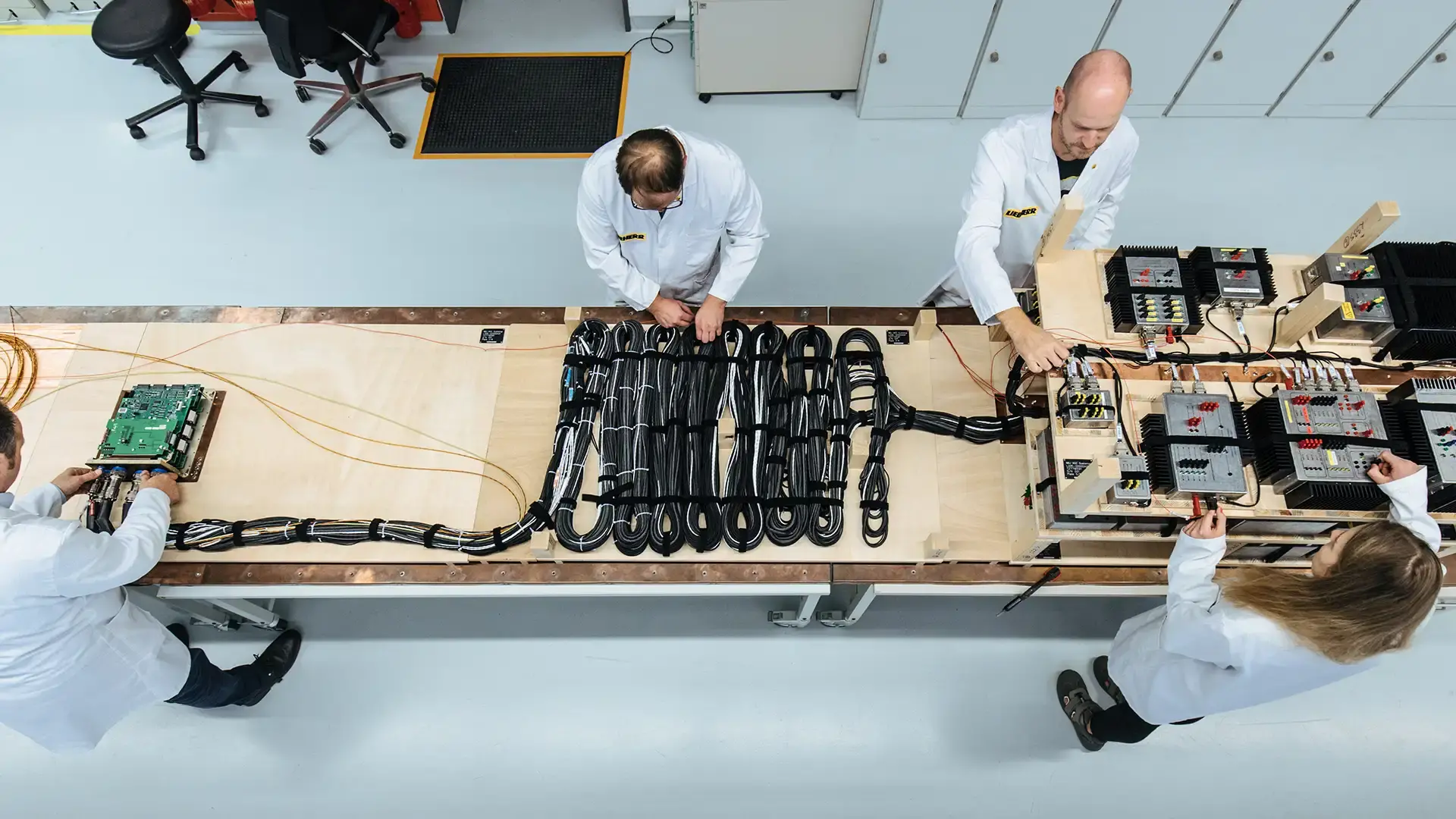

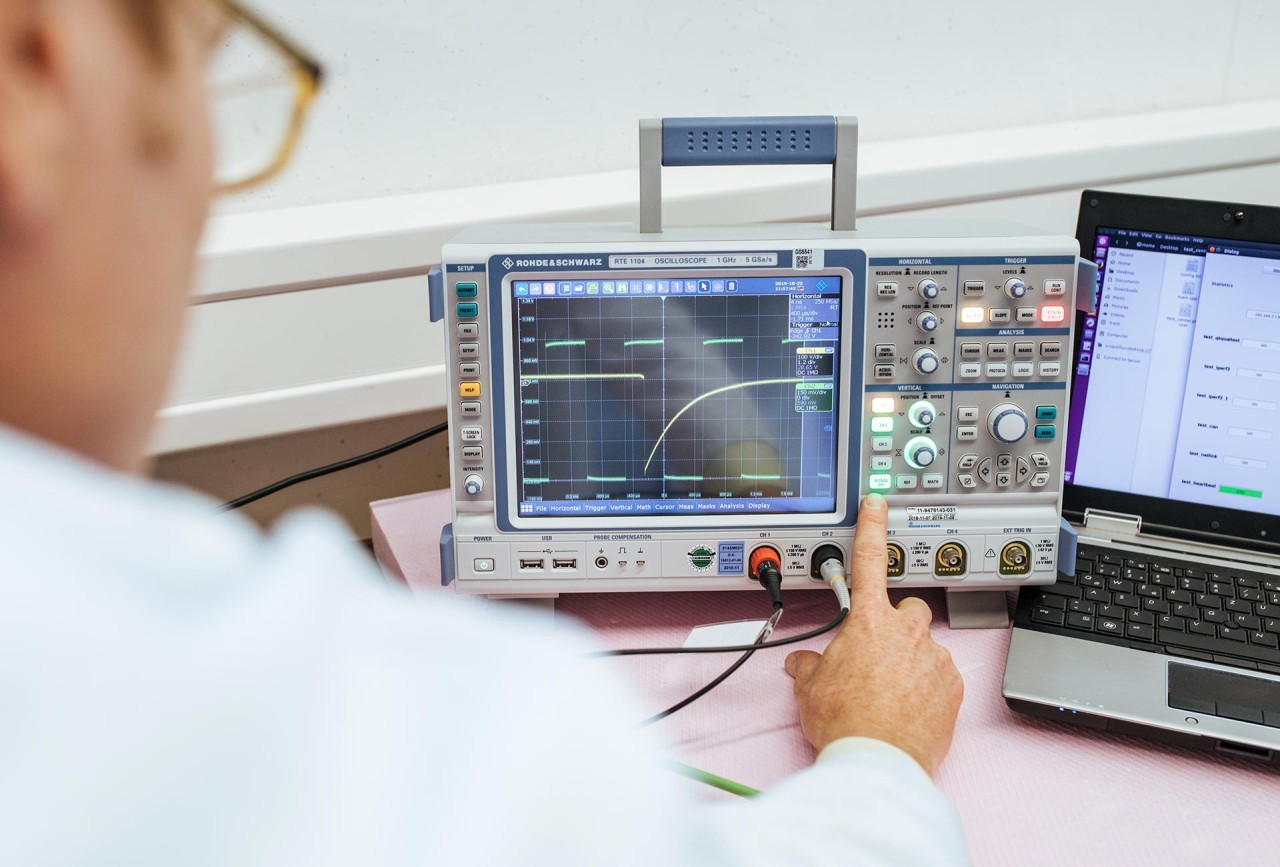

Electrical tests

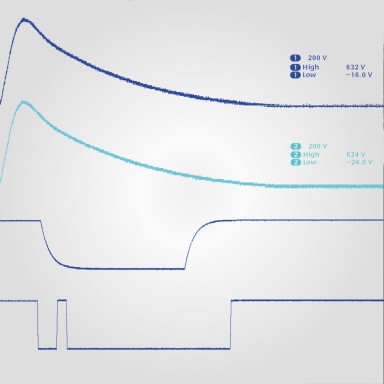

Electrical tests play an increasingly important role in the registration of electronic products. Essentially, they can be grouped together as follows:

- Lightning Induced Transient Susceptibility

- Electrostatic Discharge (ESD)

- Voltage Transients (Spike, Surge, Burst)

- Further Electrical Tests

Material analyses and examinations

The laboratory is equipped with the latest technology to offer the following options for development-related examinations, special analyses as well as series monitoring:

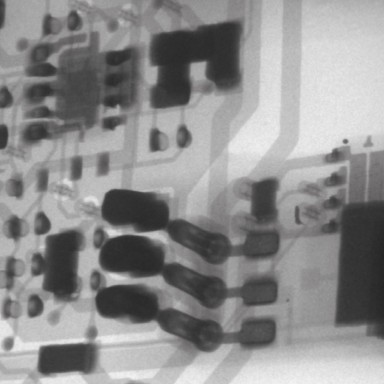

- X-ray examinations

- X-ray fluorescence spectroscopy

- Microsection preparation

- Optical examinations

Development services

In addition to individual tests or complete analyses of your electronic assemblies, Liebherr also offers you individual development services. We accompany and support your product from the idea to series production and beyond.

Electromagnetic compatibility

Parts are tested for electromagnetic compatibility inside an EMC chamber. An antenna is used to create electromagnetic fields, to test how the electronic parts react to them. We can also test which electromagnetic waves are produced by the part being tested. The chamber is electromagnetically sealed off from the outside world to simulate an open space without interfering, reflecting radiation.

These customers, among others, already trust in our electronics solutions:

Test Center for electronics enquiry form

This form is intended to assist you with an initial test request. Let us know your testing requirements. We will contact you to clarify and specify the details.

We look forward to welcoming you!