Gear technology and automation systems

Gear technology and automation systemsPrecision. Speed. Quality.

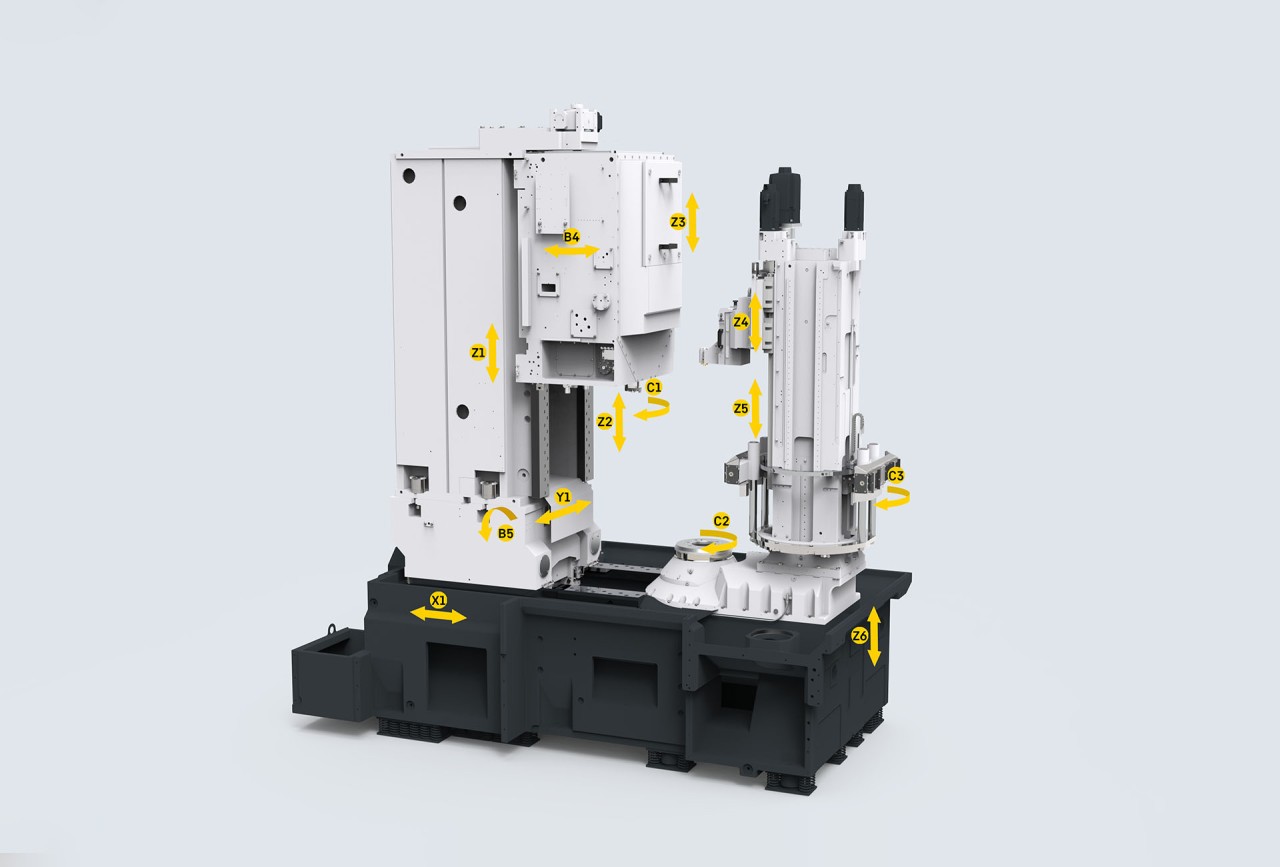

The Liebherr LS 400 EM gear shaping machine’s powerful machine design: combining quality, flexibility and efficiency

The machine concept for the LS 400 EM gear shaping machine from Liebherr represents the cutting edge in versatility and efficiency. This manually loadable machine can be used for wet and dry machining and promises complete Liebherr quality coupled with maximum flexibility. The use of premium components and powerful drives guarantees excellent quality over the product’s entire life cycle. Despite its power and impressive functionality, the LS 400 EM is remarkable for its exceptionally compact machine body that requires only a minimal footprint. This machine not only offers high productivity but a wide range of components at a minimal cost.

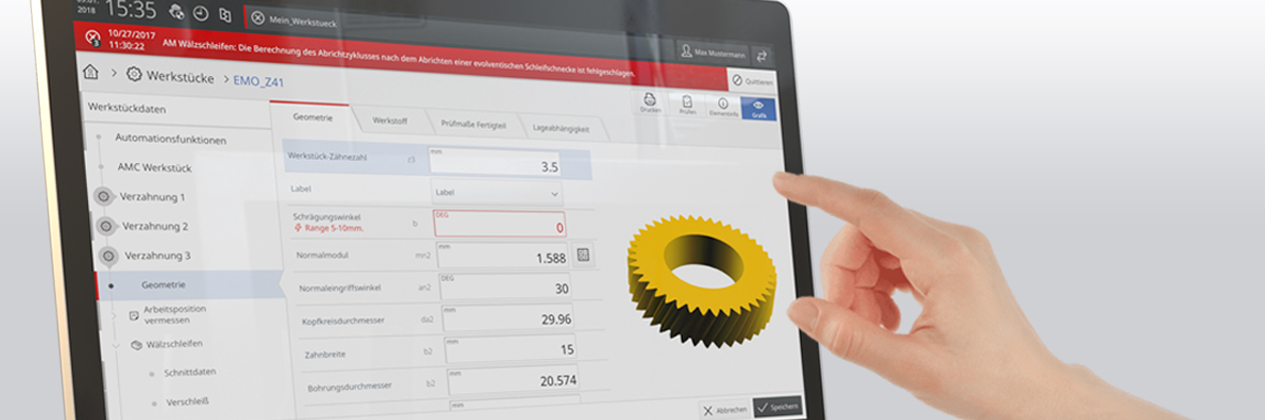

The LS 400 EM comes standard with a modern control design and the LHGearTec touch-based user interface for intuitive and efficient control.

Highlights

- Machining workpieces with a max diameter of 400 mm and shafts with a max shank length up to 500 mm

- High rigidity guarantees the best machining quality

- Heat-proof machine bed with perfect chip removal

- Directly driven machine table to satisfy the most demanding quality requirements

- Wet machining is standard

- L-doors for perfect accessibility and crane loading from above

- Optionally available with a handling device (crane)

- Comes standard with comprehensive software functionality

- Machine is ready for quick installation and startup straight out of the box

- Exceptionally small footprint

- Optimum accessibility for servicing and maintenance

- Short delivery times and minimal initial invest

Technical data

| Module | 5.00 mm |

| Workpiece diameter | 400 mm |