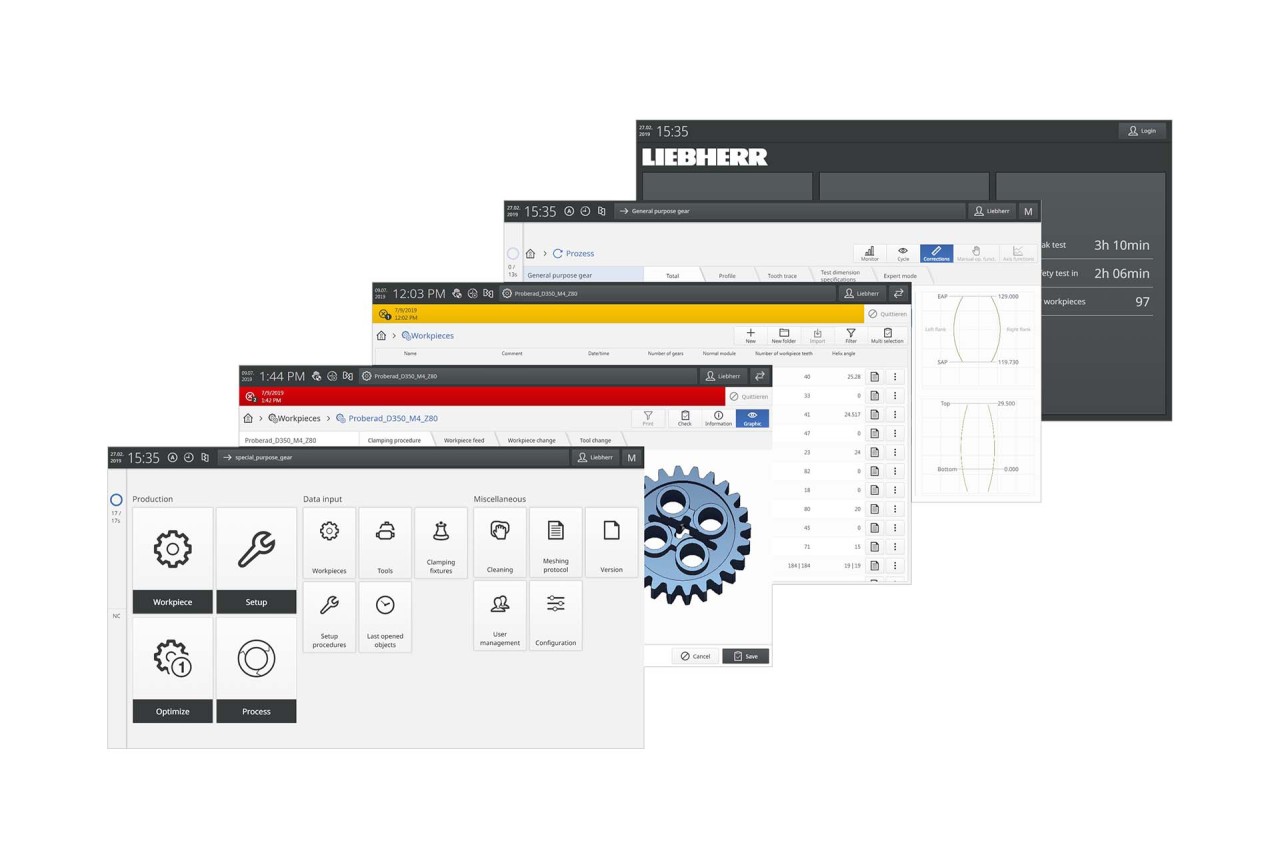

Simple control with the Liebherr user interface

The programming system by Liebherr: 25% faster setup time

With the LHGearTec software, the system constantly guides users when entering workpiece and tool data, as well as during workpiece correction and process monitoring. The user guidance was redefined in intensive cooperation with designers and users. Attention was also paid to the consistent integration of the control system in factory processes with open interfaces for both measurement processes (closed loop) and MES/MDE/PDA interfaces.

Download

LHGearTec demo version

Here you can download and test a demo version of our LHGearTec software for free:

Software download: Gear grinding

Software download: Gear hobbing

Evotion

Exciting reports from our customer magazine

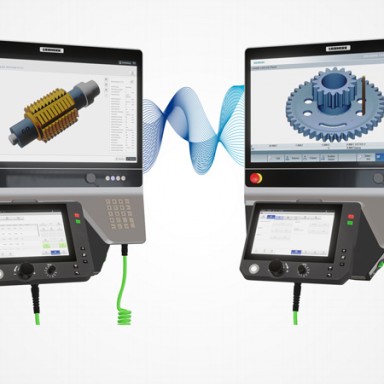

Bigger, better, faster: the new LHStation control panel

More than a new control panel: Under a 24 inch monitor, the LHStation combines the new Sinumeric One system line with the new LHGearTec software for all gear engineering equipment. This constellation makes complete machining of a gear workpiece possible.

From gear cutting to complete machining

Conventional turning and gear cutting machines can perform gear cutting, albeit with limited productivity and accuracy. But can gear cutting machines also turn and hob? With Liebherr machines, upstream and downstream processes can be integrated into machining. The LHGearTec programming and user interface, together with the Siemens control system, enables a continuous simulation and programming of all machining steps.

Design award for LHStation and LHMobile

Award for Liebherr-Verzahntechnik GmbH: The operating concept of LHStation and LHMobile won over the international jury in the “User Experience (UX)” category at the iF Design Awards 2021. The jurors awarded the coveted seal of approval from almost 10,000 submissions from 52 countries.