Gear technology and automation systems

Gear technology and automation systemsNo compromises.

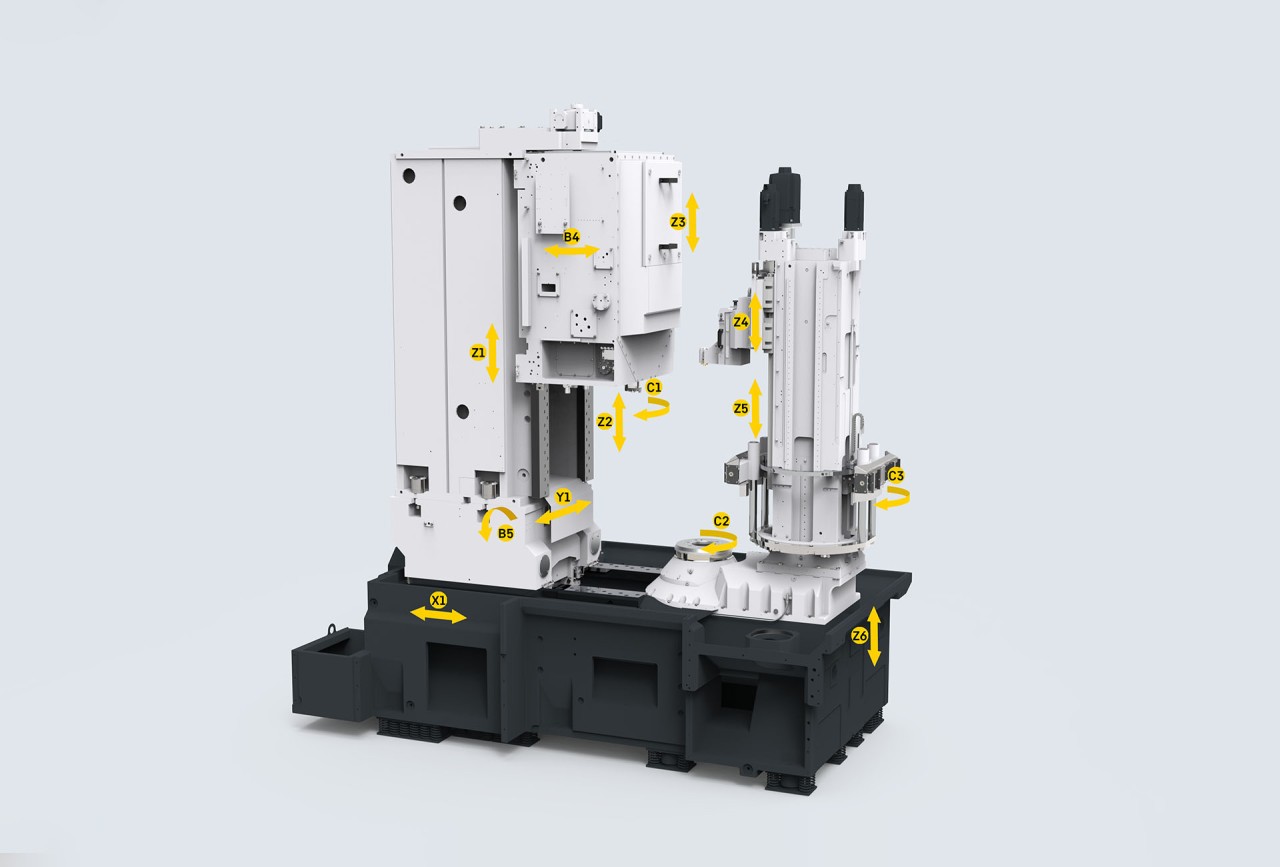

Machine design

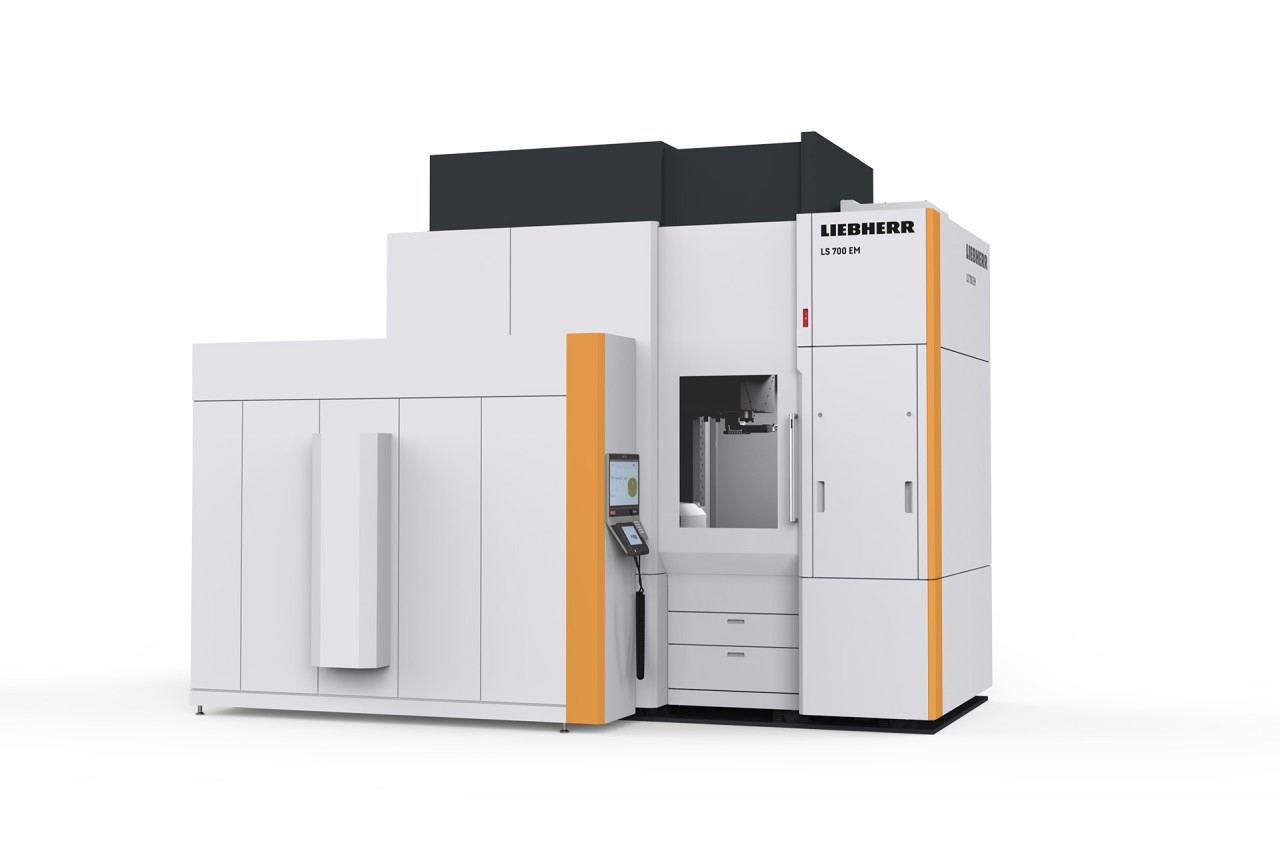

Liebherr shaping machines set the benchmark for performance. Their production efficiency goes hand in hand with their unparalleled quality.

The basis for their durability and precision is their rigid and heat-proof design, combined with backlash free drives and flat guides. Chamfering during the machining process is made possible thanks to innovative technologies like FlexChamfer.

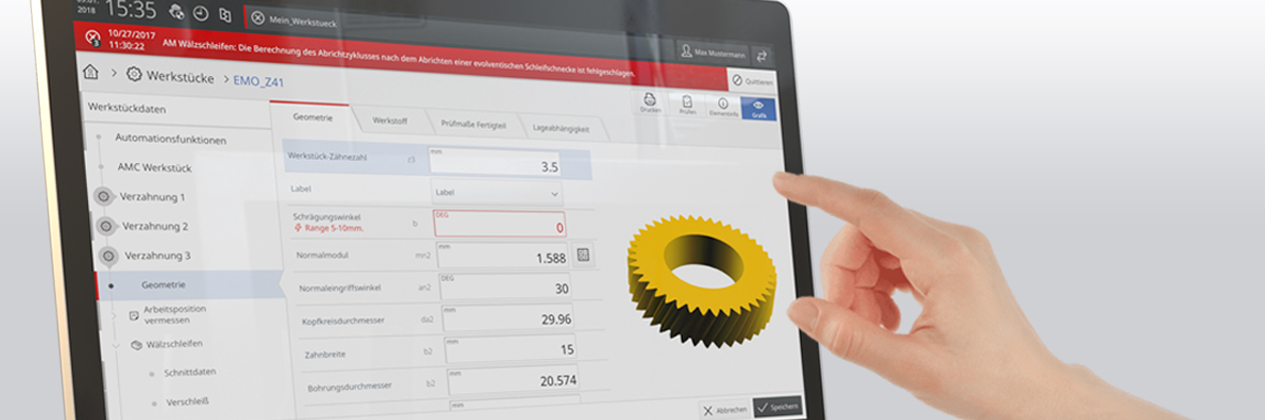

An internal ringloader provides optional automation for workpieces up to 100 kg. The Liebherr operating concept includes LHStation & LHMobile as well as LHGearTec software, meaning user friendly control is guaranteed. Chip removal has also been improved thanks to an optimized and redesigned machine bed, further increasing the overall performance of the machines.

Automation & features

Technical data

| Module | 8.00 - 12.00 mm |

| Workpiece diameter | 300 - 700 mm |

Variants

| LS 300 E | LS 500 E | LS 500 E DC | LS 700 EM | |

|---|---|---|---|---|

| Module (mm) | 8.00 / 12.00 | 8.00 / 12.00 | 8.00 / 12.00 | 8.00 / 12.00 |

| Workpiece diameter (mm) | 300 | 500 | 500 | 700 |

| Stroke length (mm) | 120 / 240 | 120 / 240 | 140 / 240 | 120 / 240 |

| Max. Hubzahl (DH/min) | 1,200 / 1,000 | 1,200 / 1,000 | 1,200 / 1,000 | 1,200 / 1,000 |