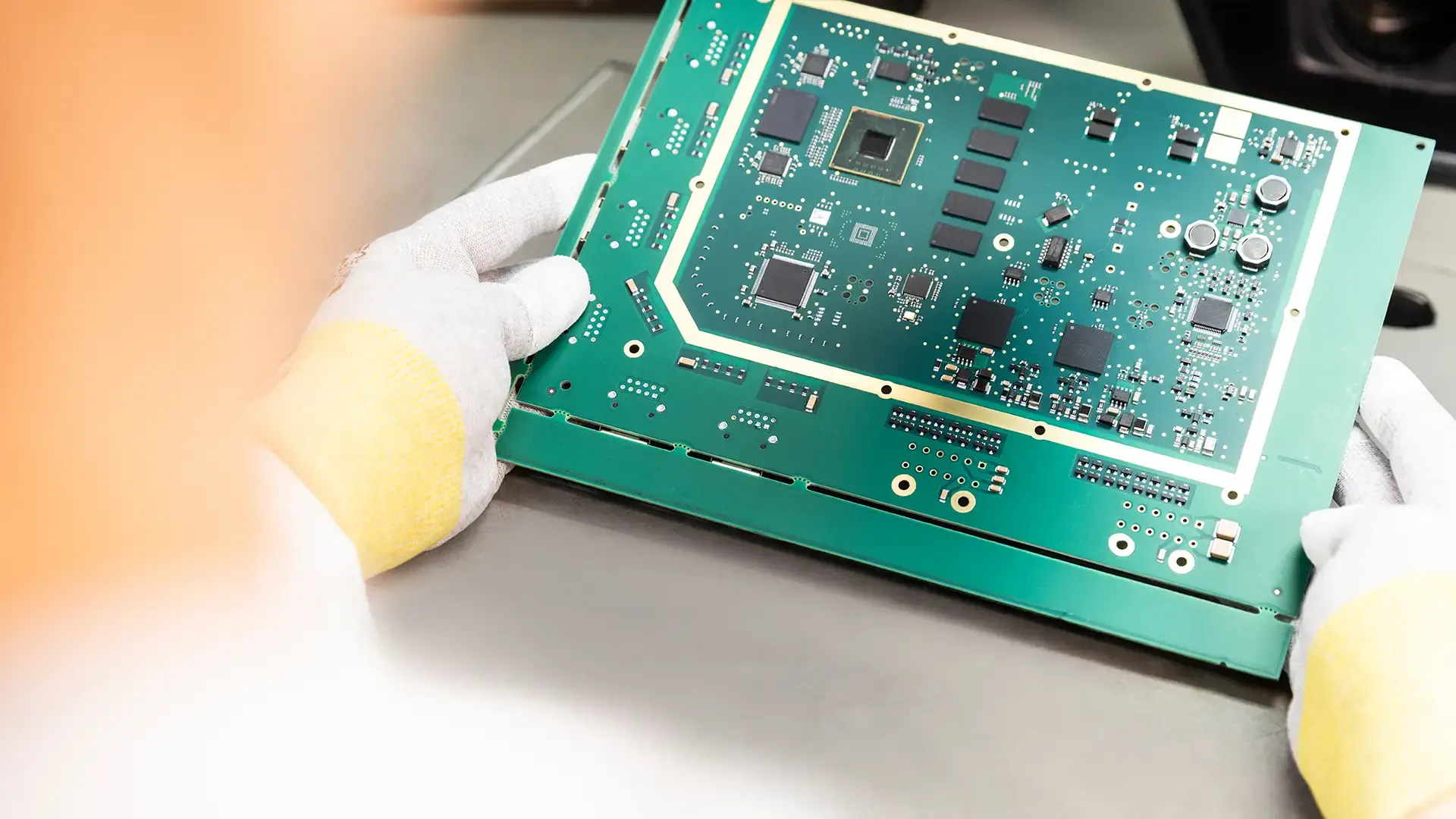

Competence center for electronics – our know-how for your product

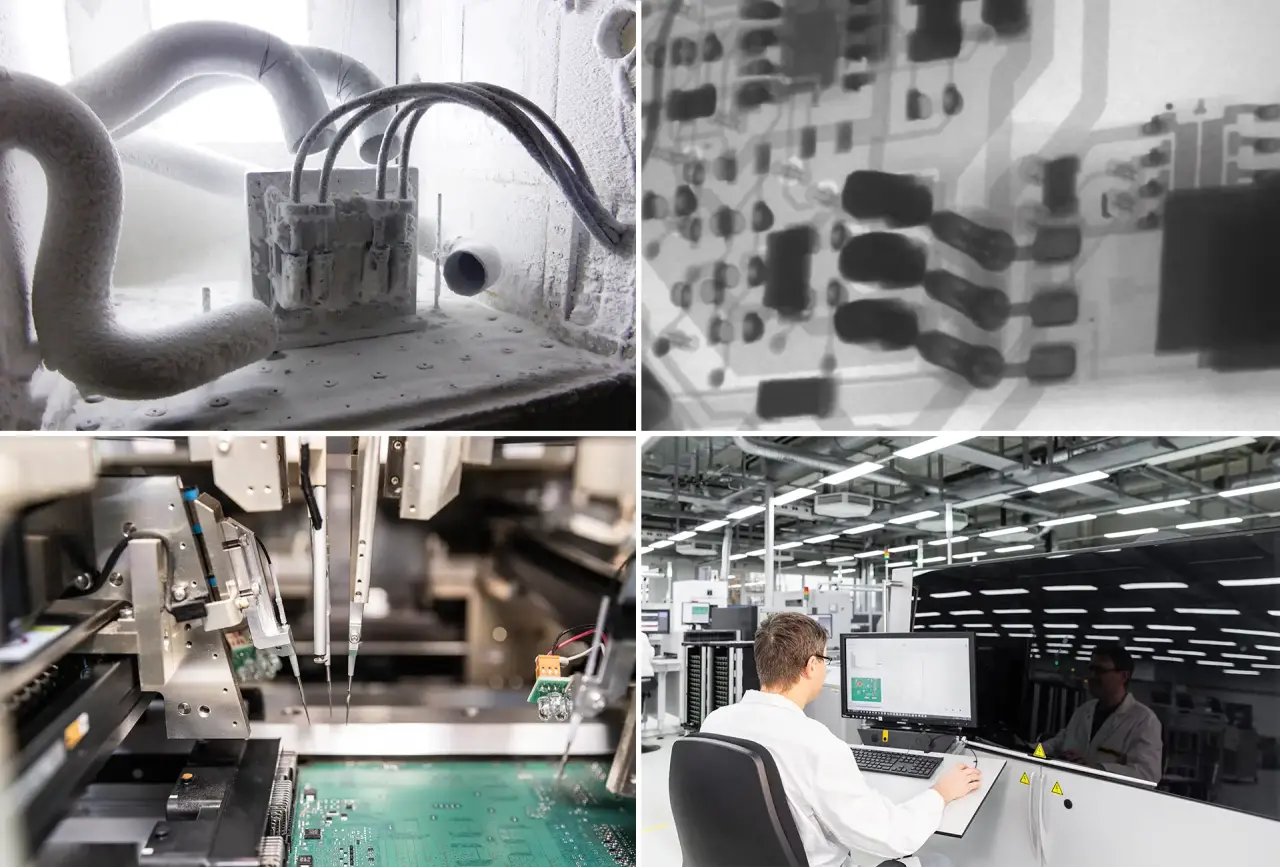

At Liebherr-Electronics and Drives GmbH, around 1000 employees currently develop and manufacture customer-specific hardware and software solutions for industry and aviation. The Liebherr Group as well as numerous external customers rely on the know-how and the high-quality electronic products from Lindau and Biberach – made in Germany.

All-round service through the product life cycle

Beginning with the procurement of materials and extending through PCB assembly and mounting, the creation and implementation of complex test concepts and qualification processes to logistics and after-sales service – our experienced EMS team is at your side, from the initial inquiry to the finished device.

Experienced partner

One-stop shop

Focus on your core competencies

Our services at a glance

EMS@Liebherr

Together, we can identify the ideal manufacturing method for economical and efficient production of high-quality electronics. With us at your side, you can concentrate on your core competencies – that's a major advantage.

Our production spectrum ranges from PCB assembly through sub-assembly with functional testing to complex final assembly. We also offer a comprehensive range of additional services.

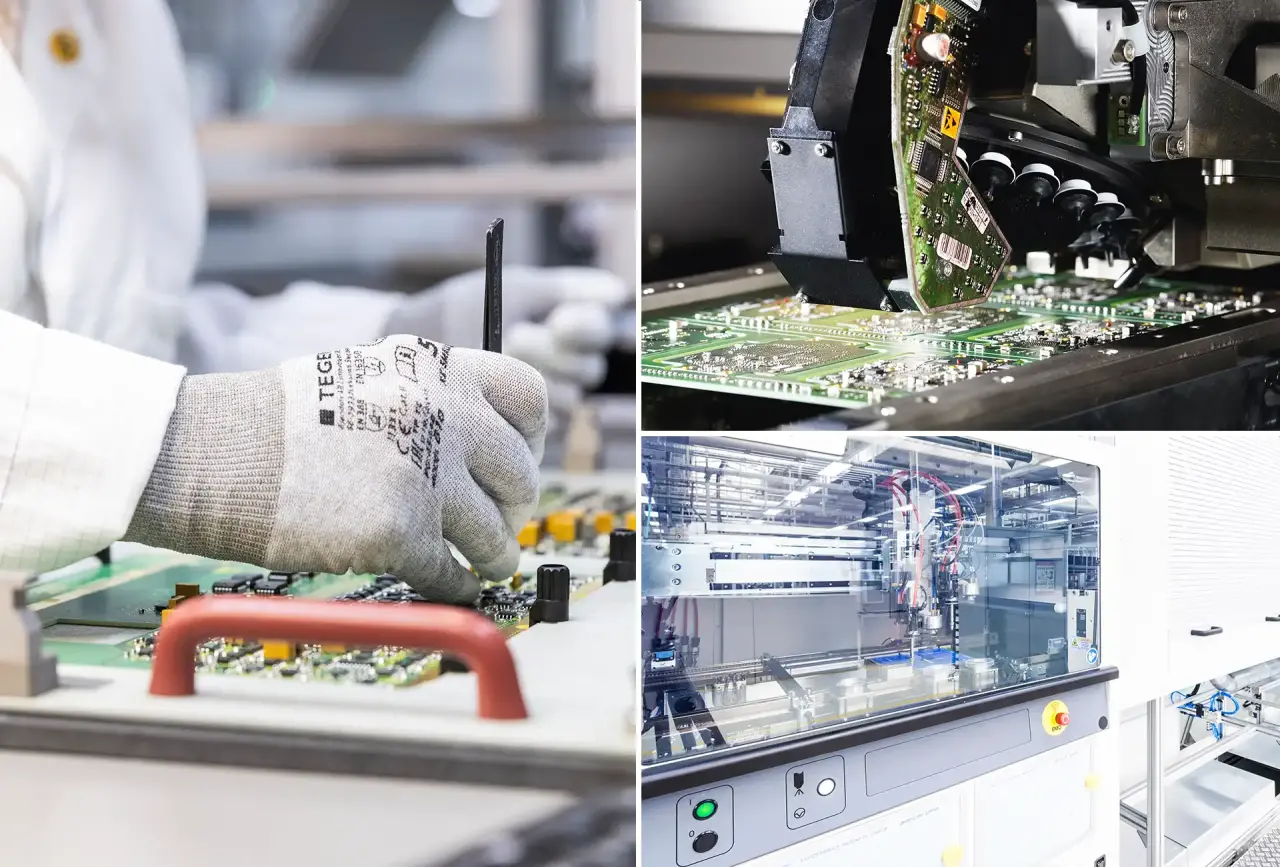

Our manufacturing services in detail

- SMT

- Reflow convection soldering

- Optical worker guidance and monitoring

- THT wave and selective soldering

- Partial and final assembly

- Force-displacement monitored press-fit technology

- Automatic gluing, dispensing and potting technology

- Automated and manual coating

- Manual and automatic depaneling

Smart data analysis and design support

By using state-of-the-art programs, we check your data for manufacturability, testability and safety during the development phase.

Our experienced production engineers can provide support at an early design stage in order to develop an economical and high-quality product. We also support you in optimising your electronics for smooth series production.

Additional services

- Design to manufacture

- Design to test

- Cost optimisation

- Manufacturability analysis

- Lead time reduction

- Focus on quality

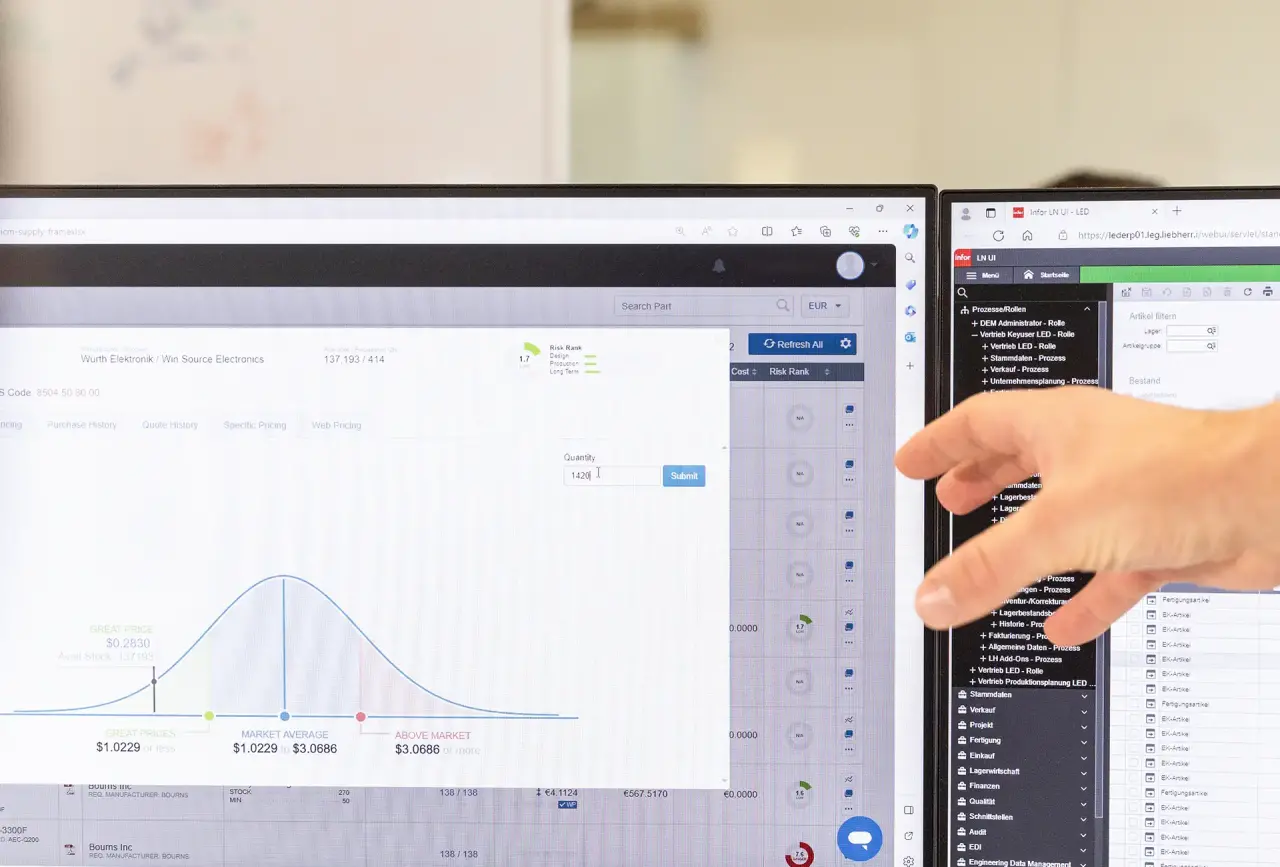

State-of-the-art software for fast and precise order processing

By using various software applications, we have quick access to the global availability of components, the demand situation and the costs. This enables us to make well-founded decisions about your request in short time.

We can also provide early feedback on the availability of your assembly by quickly and automatically checking your data package.

This enables us to ensure both an efficient quotation phase and order execution, so that we can produce your product in the desired timeframe and to the highest quality in a cost-optimised manner.

Software equipment

- Xpedition Enterprise

- Xpedition EDM Supply Chain

- Luminovo

- Valor NPI & PP

Customised test strategy

Based on your requirements, we work with you to develop the best test concept.

Test development

- Test strategy definition

- Test coverage analysis

- Test programming and troubleshooting

- Development of test adapters and functional tests (HW+SW)

- Reporting and traceability of test data

Focus on quality

With the help of modern test methods dedicated to production, we ensure the best quality for your products.

Test methods

- SPI: 3D solder paste inspection

- SMT-AOXI: Automatic optical and X-ray inspection after SMT soldering process

- THT-AOI: Automatic optical inspection after THT soldering process

- Flying probe test, in-circuit test, boundary scan

- Insulation test

- Function tests

- Vibration and temperature test

- End-of-line test

- Run-in test

- Optional X-ray analysis after THT soldering process

In addition, we also conduct development and qualification tests in our inhouse Test-Center.

Active supply chain risk management

Throughout the entire procurement process, there are numerous risks such as fluctuations in demand and price, quality issues or supplier failures. Through our active management and wide supplier network, we minimise your risks and ensure reliable delivery performance.

Supply Chain

- Over 1,000 approved and certified suppliers

- Direct manufacturer contact

- Obsolescence / component management

- Lifecycle and risk assessment of parts lists

- Long-term supply contracts

- Continuous supplier management

- Predictive forecasting

- Own database on SVHCs in accordance with REACH

- Process-controlled material supply across the entire value chain through various logistics concepts

Your reliable partner beyond production

After the delivery of your products, service is our top priority. We are happy to take on the complex tasks of after-sales support for you.

Services

- Obsolescence and change management

- 100 % traceability and batch traceability

- Long-term stockpiling

- Spare parts management

- Repair services

- Methodical failure analysis

- Analysis laboratory with state-of-the-art measuring and testing technology

Quality for a long product life

Customer satisfaction is at the heart of everything we do. Our many years of experience in electronics production, targeted training schemes for our employees and the continuous monitoring and improvement of our processes guarantee you a long term high level of quality.

Certifications

Quality management system:

- EN 9100 including

- ISO/EN/DIN 9001

- German Federal Motor Transport Authority (KBA, approval for the manufacture of all electronic vehicle parts relevant to approval)

We also have approvals that authorize us to manufacture and repair aviation products:

- EASA Part-21 & Part-145

Further certifications and downloads can be found under Certificates.

Environmental management for greater sustainability

Our environmental and energy management is based on DIN ISO 14001 and DIN ISO 50001 and is certificated.

- We take active measures to ensure operational environmental protection and improve our energy efficiency by:

- monitoring and continuously improving emissions and resource consumption

- reducing the use of chemicals and making workplaces safer (compliance with REACH and RoHS)

- avoiding waste (e.g. introducing a circular packaging concept with our customers and suppliers)

- switching to e-mobility (electric vehicles at the Lindau and Biberach sites)

- having our own charging stations for our electric vehicles

- using renewable energies (photovoltaic system in Lindau)

- Offering our employees the option of a work bike

Our services at a glance

Our factsheet provides you with a brief overview of the most important facts about our portfolio.

Are you interested in our Electronics Manufacturing Services? Use our form for your enquiry. We will get back to you as soon as possible.

- Enquiry form

These customers, among others, already trust in our electronics solutions:

In-house Test Center

Within its competence center for electronics in Lindau, Liebherr operates a test center offering testing and measuring technology at the highest level. There we simulate environmental influences realistically – for customers from the aviation, automotive and industrial sectors, among others. You can also use this test infrastructure within the scope of your EMS project.

Overview: Our test services

- Electromagnetic compatibility

- Electrical tests

- Environmental tests

- Vibration tests

- Material analyses / investigations