Journey to the Swiss Underworld

Glückauf! At the beginning of 2022, six of our digital smart cameras embarked on an exciting journey – to the mysterious depths of underground mining.

Read on to find out how our products bring light into the darkness and what role they play for an autonomous future underground.

Tunnel visions

A construction site of a somewhat different kind can be found this spring in Bern, the capital of the Swiss Confederates. Day in, day out, eight or nine Marti Tunnel AG employees are excavating new caverns for a railway station project there. Working underground is not at all easy; you definitely have to like it. Immense quantities of dust make viewing very hard, the air is humid and "tüppig" (Swiss German for sticky, especially in Bern). The only sources of light are glaring LED tubes on the tunnel walls and the machines' headlights.

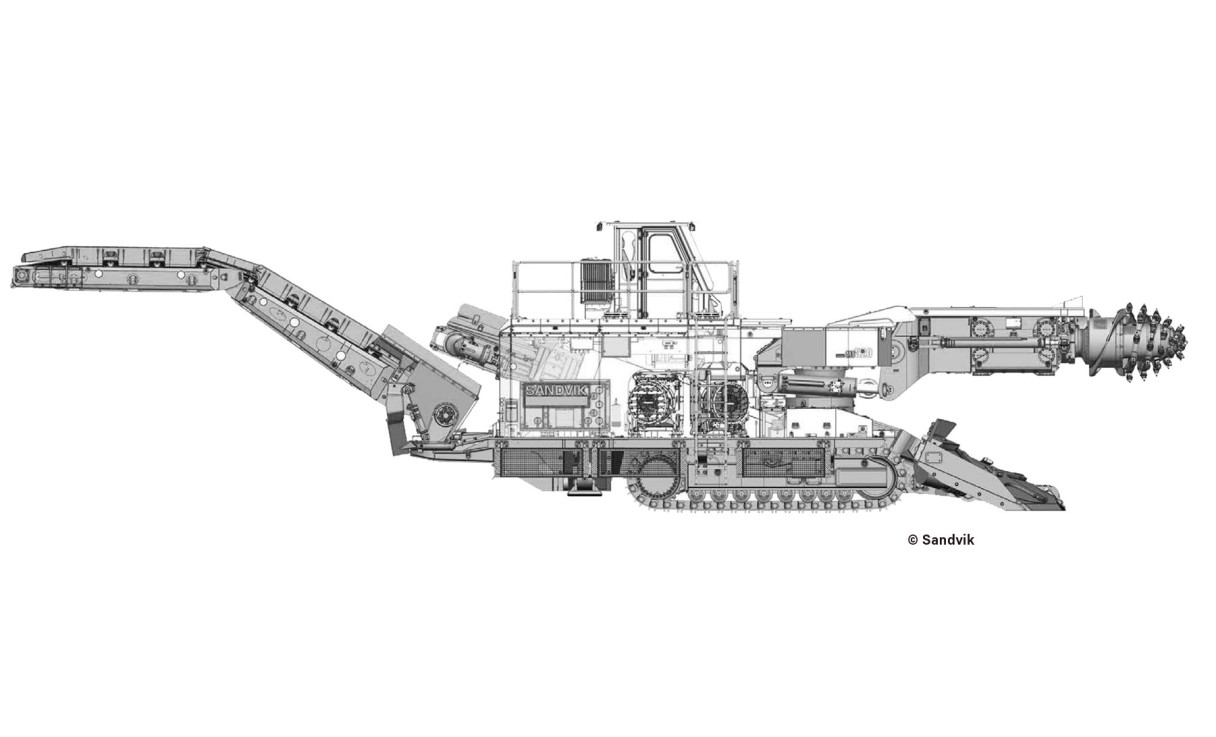

The rumbling and shaking of the special machines creates a permanent background of noise that makes communication almost impossible. It’s a job that requires a lot of skill, flexibility and endurance in particular — and therefore deserves the highest recognition. Similar to deep-sea fish, you can also find very special machines a few metres underground where the environmental conditions are extreme. Let us introduce the roadheader, a key protagonist on this construction site that definitely steals the show from crawler excavators and wheel loaders.

Breakthrough under the earth

Roadheaders are suitable for a wide range of applications, including mining, tunnelling and quarrying of raw materials such as limestone. A boom-mounted cutting head mills off the cavity piece by piece. Depending on the specific requirements of the application, the cutting head can be arranged either transversely or longitudinally. The so-called header machine is therefore the perfect solution for creating new underground cavities or refurbishing dilapidated tunnels.

The Swedish Sandvik Group is the creator of the MT520 roadheader used in Bern. The company is about the same size as Liebherr and produces machines and tools for various sectors such as mining, metal cutting and rock removal. Sandvik can proudly call itself the world market leader in the field of roadheaders.

So without the sharp claws of Sandvik's MT520, progress is slow — but only the right partner can help it achieve true greatness.

Stowaway with eagle eyes

Six of our digital cameras got the opportunity to accompany this special machine on its mission. As their role is to provide a surround view in the operator's cab, they make the demanding work underground safer and more efficient. Although they differ in size, these partners have one thing in common: they are tough but still a real eye-catcher.

Get an idea of how well they complement each other.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Data protection settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).The enormous forces at play in underground mining pose great challenges on the components in our machines. We, therefore, subject the components to intensive tests before we use them in our machines.

The test winner — small but mighty

Before its use on the special construction site in Bern, Sandvik put our MDC3 digital smart camera through its paces. But even the biggest shock and vibration loads could not affect the reliability and quality of the images delivered.

The final endurance test: the extremely poor viewing conditions underground. Darkness and intense dust usually pose a significant challenge to cameras. However, the MDC3 did not disappoint in this test either. Due to its integrated high-performance imager, the digital camera is able to show every single detail on the display in the operator's cab even in very dark environments. In short, the MDC3 emerged as the proud test winner in Sandvik’s performance test.

"Liebherr’s MDC3 convinced us in particular due to its high quality and robustness”, says Uwe Restner, product manager for roadheaders and digitalisation at Sandvik.

Completely equipped — with six cameras for comfortable surround view

A bright idea

However, the machine manufacturer still faced one problem. The cutting process whirls up huge amounts of dust and water, which settle on the cameras as a layer of crystallization. In order to prevent this physical process from occurring and ensure clear viewing, Sandvik installed an air nozzle in front of each Liebherr camera.

Unusual circumstances require creative solutions.

When it comes to future tele-remote operations, the most decisive factors in the choice of the camera are its reliability and latency. The MDC3 was our first choice here.

The autonomous construction site — soon no longer a pipe dream?

Sandvik still has big things in mind for its roadheaders: in the future, the machine manufacturer also wants its machines to be compatible with tele-remote operation. However, such remote machine control requires a high-resolution and, above all, reliable surround view — even under extreme conditions such as heavy vibrations. This application therefore requires highly reliable and intelligent cameras.

If a camera were to fail during operation, this would not only interrupt the tele-remote operation, but also lead to machine downtime and the resulting additional costs. Promising digital camera technology and optimised coupling possibilities with the machine controls have also encouraged Sandvik to switch from analogue to digital.

Future development towards digitalisation and autonomy on construction sites certainly promises to be exciting.