8 minutes | magazine 01/2022

Crane Planner 2.0

Andrew Lloyd is the Senior Engineer at Select Plant Hire Co Ltd. in Cambridgeshire, Great Britain. His everyday work is to plan crane jobs of all types.

Andrew Lloyd - Lifting Engineer at Select Plant Hire Co Ltd.

Playing with cranes to achieve perfect planning

He uses the Crane Planner 2.0 tool from Liebherr a great deal for his work. In the Engineering Matters podcast entitled “#131 - Cranes: How to Plan a Lift”, he explains why Crane Planner 2.0 has become so important to his work. The hosts of Engineering Matters also speak to Wolfgang Boos, a Product Manager with us, and Christoph Mai, a Product Manager at Liebherr in Nenzing. Give it a listen.

“It is always possible to plan a large crane for a job, which will complete the lift easily. The challenge in the planning process, one which is always my objective and motivation, is to make the job as simple and efficient as possible”, says Andrew passionately as he explains his intention: “I want to make jobs economical, sustainable and safe. However, that is often rather complicated.” He pleads for engineers to involve job planners like him in the design of their structures. Minor modifications to individual components or procedures can make the process significantly more straightforward and result in massive savings in the installation work.

Crane Planner 2.0 includes all relevant factors

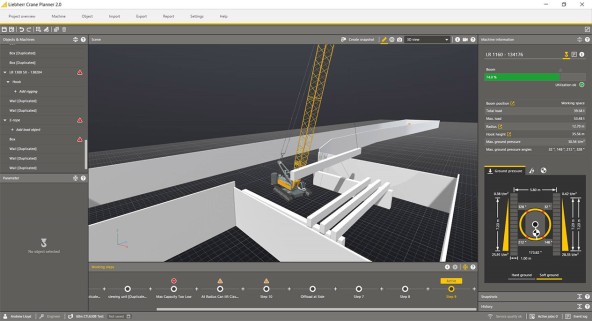

Liebherr developed Crane Planner 2.0 to cover all this – professional hoist planning with all the relevant crane data and which can be completed easily. Andrew is delighted with the tool and uses it almost every day: “All the information I need is in the system. To plan the job, I first have to enter the available information. For example, buildings, roads, obstacles or a pre-defined crane model. If there are 3D models of the site, I can include these very easily as well. If there are only simple drawings, I have to create the relevant environment myself.” One of the main points about Crane Planner 2.0 is that it requires neither particularly high performance hardware nor any knowledge of CAD programs. At the same time, our engineers and software developers are constantly working on new functions and the integration of additional crane models.

Select Plant Hire Co Ltd.

With over 30 years’ experience, Select Plant Hire, has built an excellent reputation as a large and diverse partner to the construction industry. The company provides technically advanced cranes and hoist equipment, as well as site accommodation, piling & concrete equipment, fleet, general plant and logistics services in the UK and Australia. Great emphasis is placed by Select on logistics, engineering, safety and efficiency.

“The great thing is that I can play with the site situation and the crane, in other words I can simply try out different positions, configurations and procedures. Crane Planner calculates the correct lifting capacities after every change – I could never evaluate that volume of data manually, not to mention the enormous time savings”, says Andrew enthusiastically. Andrew’s experiences with Crane Planner 2.0 mainly involved crawler cranes from LiebherrWerk Nenzing GmbH, which were the first to be included in the software package. He believes that the application potential for mobile cranes from Ehingen is massive, as more and more of them are included in the system. He continues: “Particularly mobile cranes, such as the LTM 1750-9.1 with systems like VarioBase® and VarioBallast® are now so complex that there is no chance of finding the correct lifting capacity for every position in a single table as there are so many possible configurations.”

Crane Planner 2.0 is a fantastic tool for excellent job planning.

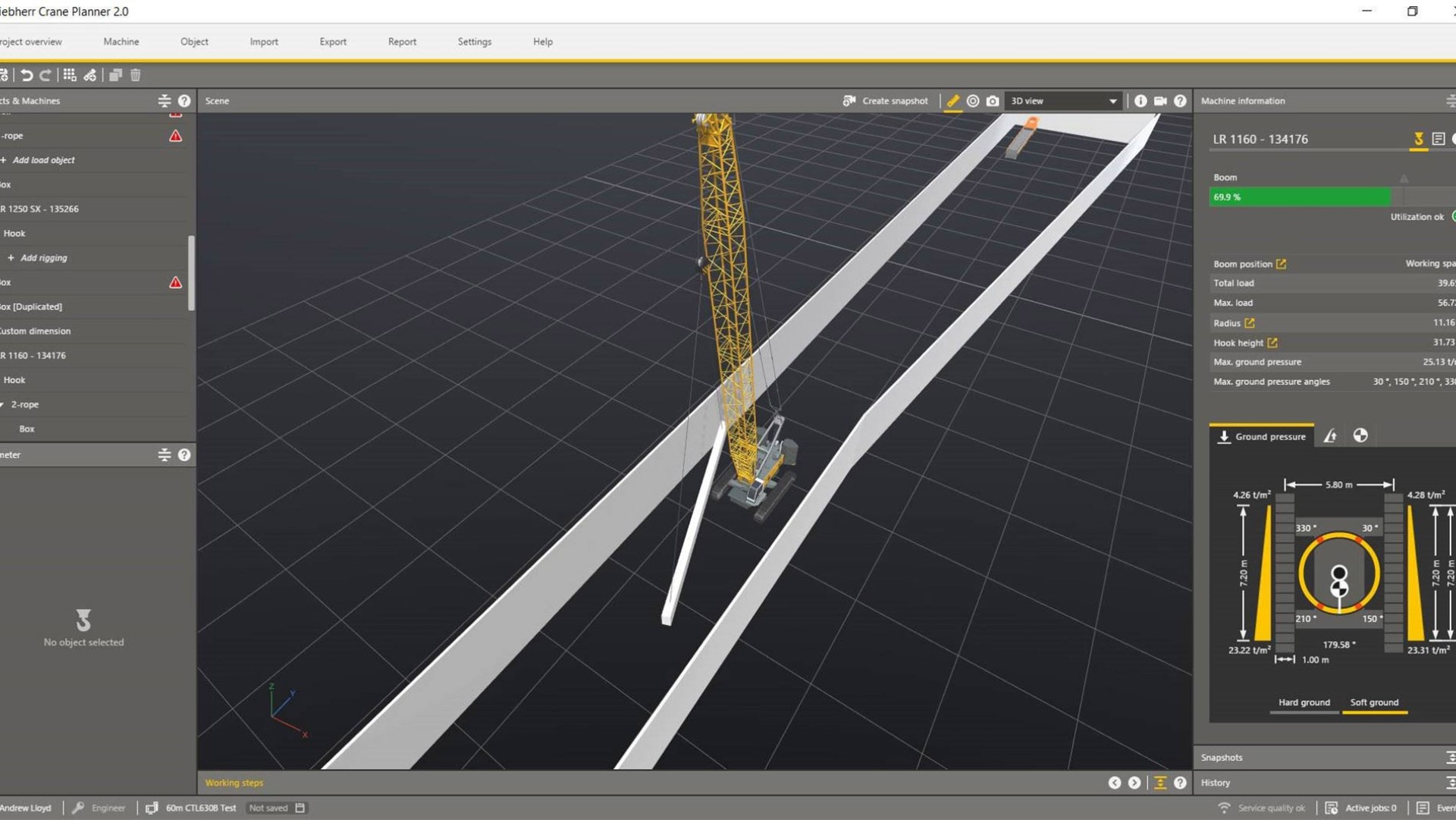

Three-dimensional for better understanding and clarity

For a simple two-dimensional planning process, there are so many factors that it is very difficult to draw them all. “When I find a solution, I must be able to explain it to the management team so that they are certain to understand it. You also have to look at multiple 2D drawings simultaneously to create a 3D world and plan the processes in your head. That is incredibly complicated”, Andrew continues. “I can simply display all the processes in the 3D world in Crane Planner. The processes are clear and comprehensible. And the relevant data are reliable and complete.” As the precise machine data are calculated using the same methods as the live data for mobile and crawler cranes, they are absolutely reliable. That also includes the weight of the hook and rope, for example, as well as the ground pressures. Crane Planner also produces a professional report, including processes for perfect communication with the customer, at the touch of a button.

Clear and comprehensible: space requirements, slewing radii, working range limits, edges and ground pressures can be taken into consideration easily in Crane Planner 2.0. The processes can be planned superbly.

Think outside the box to create new solutions

In the podcast, Andrew shows an example of a job which he was able to plan much more easily and efficiently using Crane Planner. It involves a bridge building job in London with lots of individual components in a restricted environment and a great many obstacles. “Originally, the job was to be completed using a large crawler crane hoisting the components from outside the site into position with a large radius and lots of crane equipment. The job would have lasted a very long time due to the massive number of individual components and would have been very expensive using this heavy duty crane,” says Andrew and explains his alternative solution: “There was already a LR 1160 on the site and I wanted to do the job using this small crawler crane. To manage it, the 160 tonne crane had to unload from truck and manoeuvre it through a long, narrow area with the girders on the hook. It was very narrow, but I was certain that it would work. However, I also had to persuade the decision-makers at the site of this.”

Crane Planner 2.0 Version 1.7

Since the release of the latest version, now in addition to the LTM 1750-9.1 the mobile cranes LTM 1650-8.1, LTM 1450-8.1, LTM 1300-6.2, LTM 1250-5.1 and LTM 1230-5.1 are also available for planning work. Additional telescopic mobile cranes will be added to the Crane Planner 2.0 at regular intervals. The LTM 1350-6.1 will be the first of these. Users of the previous version will enjoy the benefit of the new crane models and functions automatically and free of charge after the update. These also include the new distance tool which enables objects such as machines and buildings to be positioned relative to each other with centimeter precision.

Find out more about Crane Planner 2.0 here: www.liebherr.com/craneplanner

Andrew went through the scenario with Crane Planner 2.0, convincing himself completely that the idea was feasible and when it was 100 percent certain, he demonstrated the processes to his customer. Every step, obstacle and solution was clearly shown in the simulated 3D world – the positioning of the truck and the crane, all the movements of the crane, the positioning of the bridge components and the movement routes through the eye of the needle. The customer was persuaded by Andrew’s professional solution, completed the job as proposed and managed to save a great deal of time, money and effort.

Link to podcast: https://engineeringmatters.reby.media/2021/10/21/131-cranes-how-to-plan-a-lift/

This article was published in the UpLoad magazine 01 | 2022.