Slewing bearings and slew drives

Turning your power: Globally strong. Locally positioned.

Application-specific: Slewing bearings and slew drives for every need

Over 350,000 slewing bearings and slew drives delivered worldwide are proof of Liebherr’s technological expertise. Keeping the most diverse applications running, our slewing bearings prove themselves day in, day out. Robust, durable and application-specific describe the slewing bearings from Liebherr, turning in a wide range of applications, in all weight and diameter classes.

First glance: Slewing bearings and slew drives

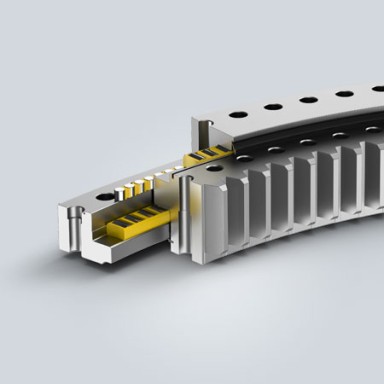

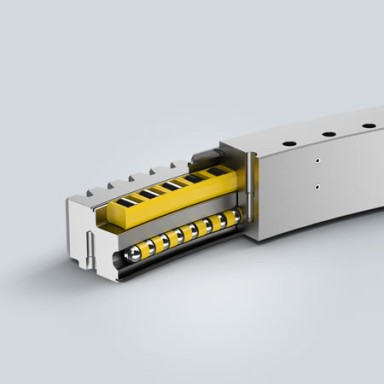

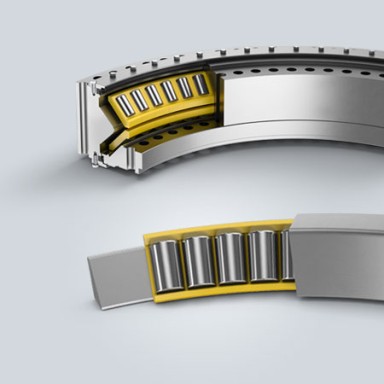

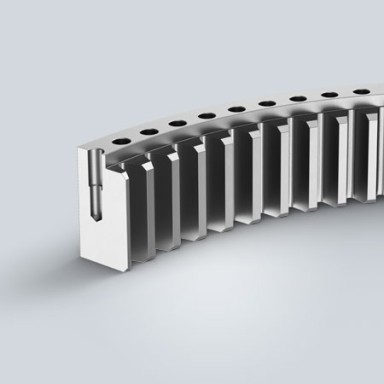

Liebherr manufactures customer and application-specific slewing bearings. Depending on given requirements, various sizes and designs are available. This includes ball bearings for low and medium loads as well as roller bearings for medium to high load applications. Additionally, the product range features slew drives as well as special designs such as tapered roller bearings or combined roller and ball bearings.

Special treatment for slewing bearings: features and services

Application-specific and customized slewing bearing solutions are key values to the product range. Discover the highlights of our extended product range with our special features and selected services.

Features that make a difference

Liebherr slewing bearings are one of a kind: equipped with special features they perform outstandingly.

Comprehensive services for slewing bearings

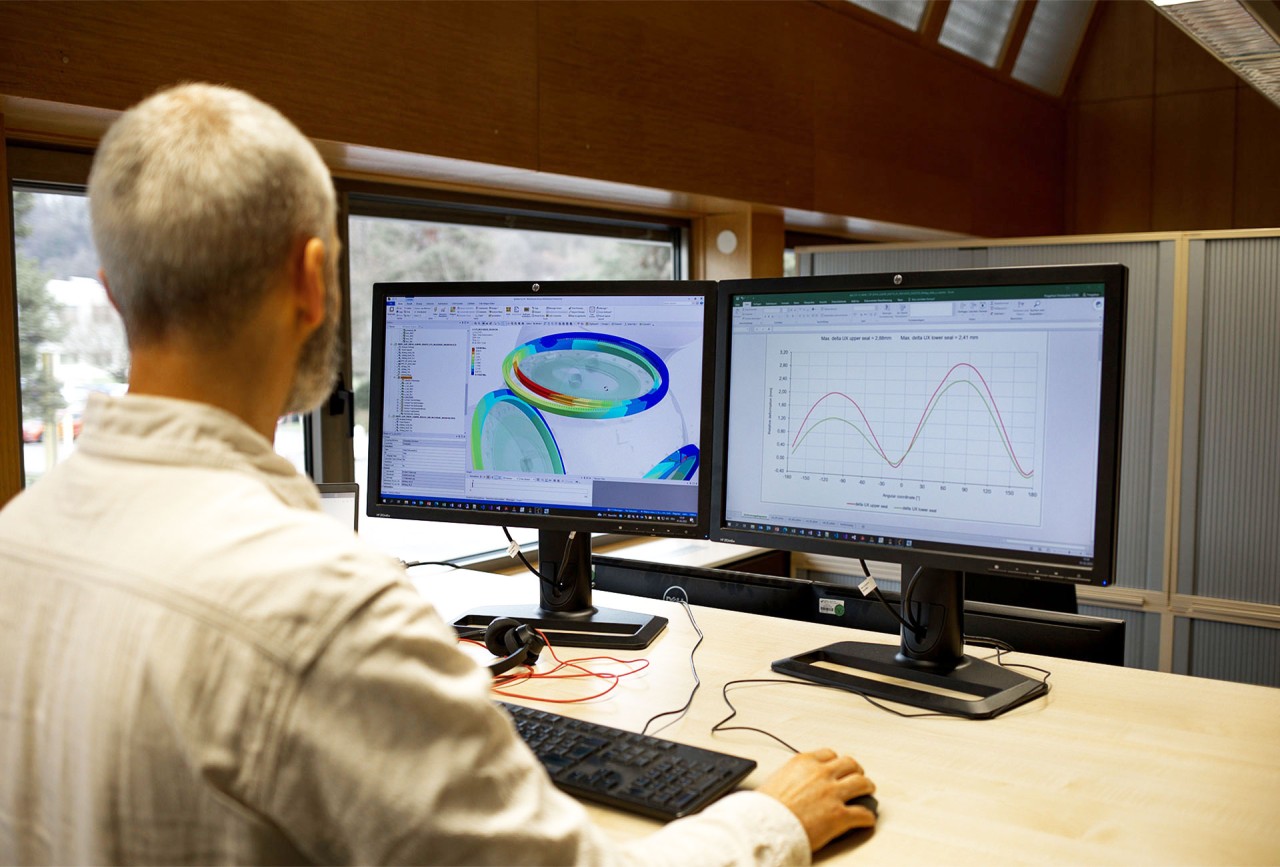

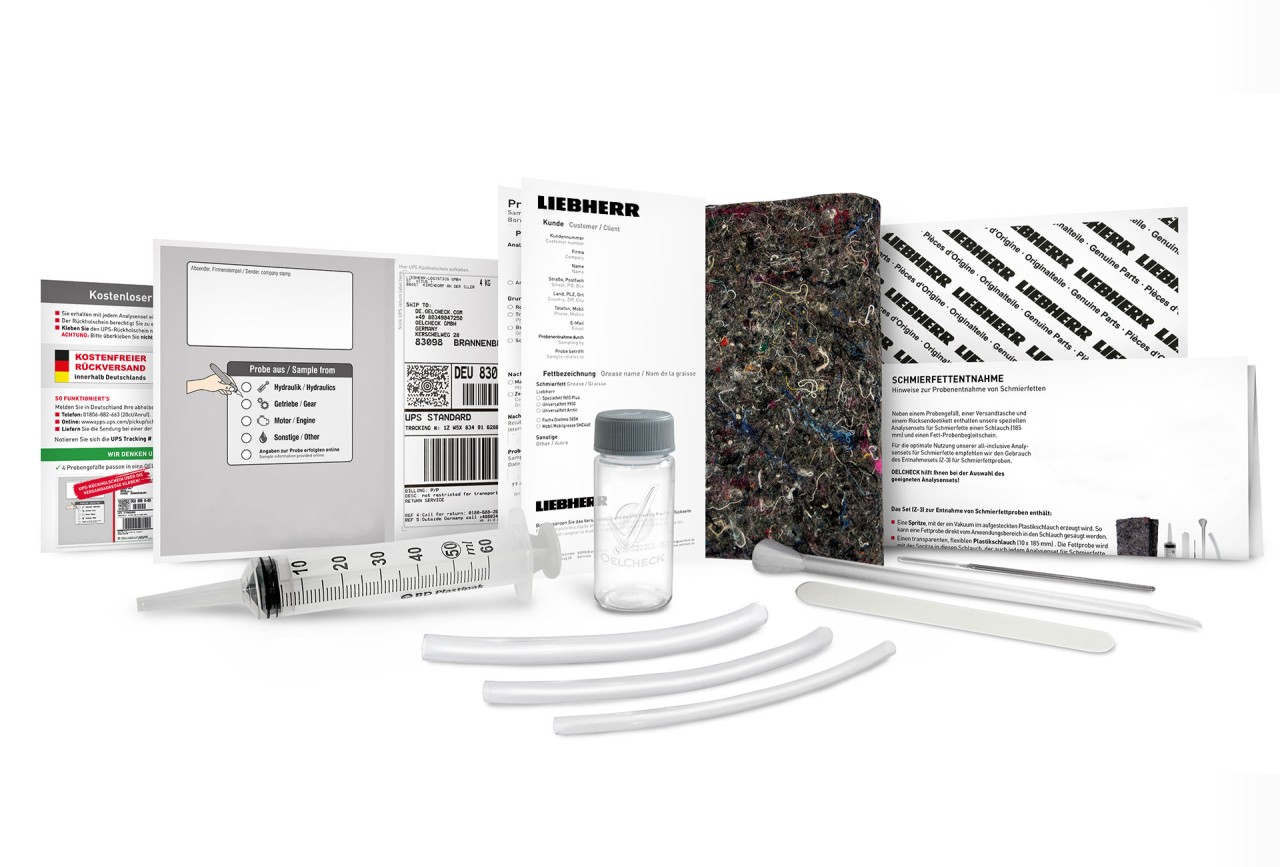

Continuous operation and maximum flexibility: Your requirements characterize our slewing bearings. And with our own calculation models, state-of-the-art quality management or an easy-to-use grease analysis kit, we are always there when you need us.

Get in touch

Contact our local sales team or follow us on our LinkedIn channel.

More topics that might be of your interest

Globally strong. Locally positioned.

Over 20,000 slewing bearings leave our plants every year, produced for use worldwide. The bearings are manufactured in the factories at Biberach an der Riss (Germany), in Monterrey (Mexico), in Guaratinguetá (Brazil) and in Dalian (China). These slewing bearings may vary in dimensions and versions in accordance with customer specifications.

Globally strong. Locally positioned.

Over 20,000 slewing bearings leave our plants every year, produced for use worldwide. The bearings are manufactured in the factories at Biberach an der Riss (Germany), in Monterrey (Mexico), in Guaratinguetá (Brazil) and in Dalian (China). These slewing bearings may vary in dimensions and versions in accordance with customer specifications.