Aerospace and transportation systems

Aerospace and transportation systems

Engines and nacelles

Engines and nacelles

Expertise for more efficient aircraft propulsion

Based on its vast experience in actuation and thermal management for aircraft applications, Liebherr collaborates with engine and nacelle manufacturers to develop and supply critical components such as gearboxes, heat exchangers, valves, and thrust reverser actuation systems.

Liebherr's extensive expertise and commitment to quality make it a reliable partner, serving various engine types and ensuring efficient and dependable performance across all applications.

Solutions for engines and nacelles

Liebherr offers a range of critical components and systems, including gearboxes, heat exchangers, valves, and thrust reverser actuation systems. Liebherr’s innovative products enhance the efficiency, reliability, and performance of gas-turbine engines and nacelles, contributing to overall aircraft safety and performance.

With a focus on continuous improvement and cutting-edge technologies for engines with ultra high bypass ratio as well as hybrid propulsion concepts, Liebherr remains an important partner for the engine OEMs in order to meet the industries sustainability targets.

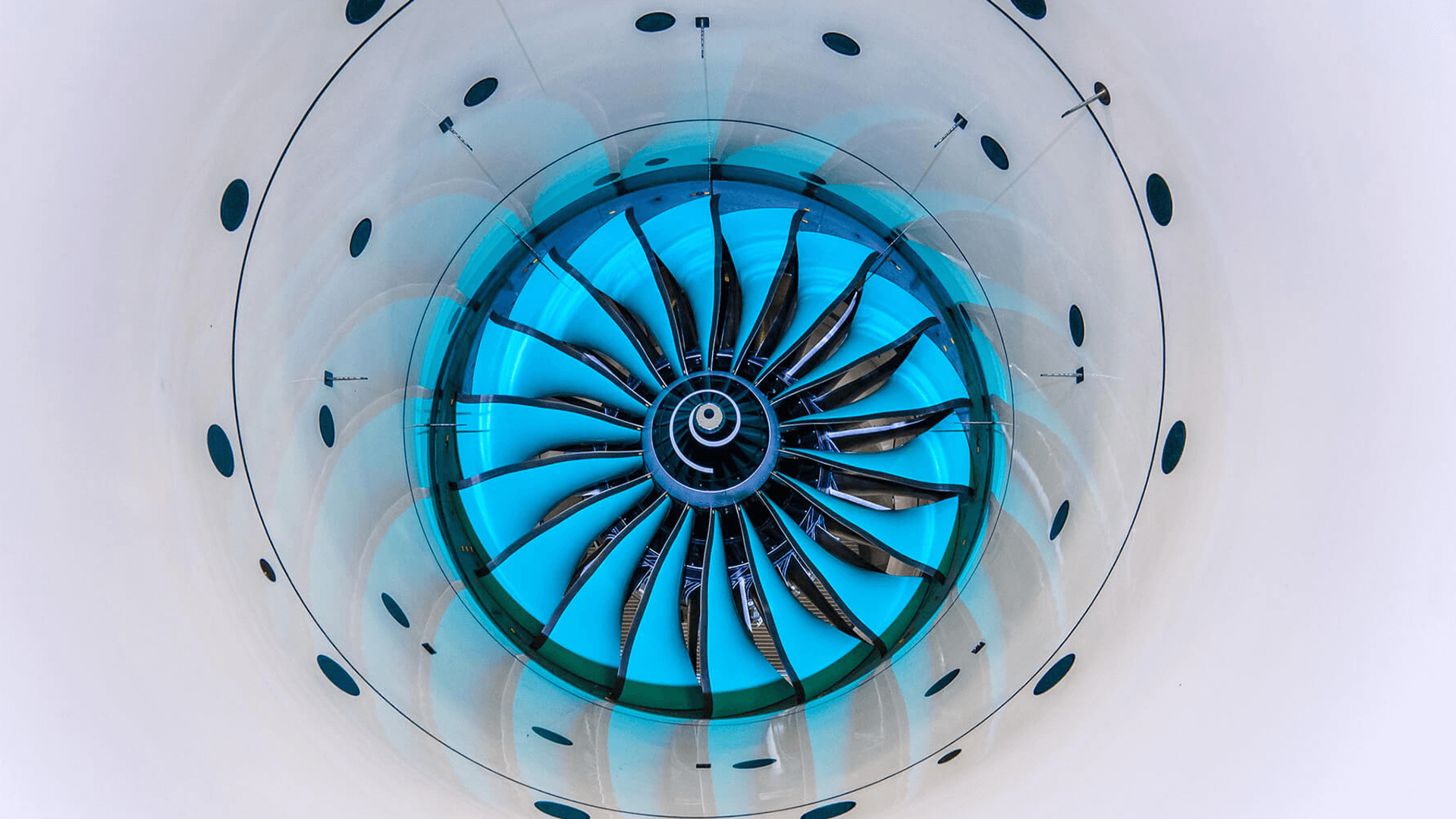

Rolls Royce's turbofan engine UltraFan® increases efficiency

The future geared turbofan engine of Rolls Royce, called UltraFan®, is using Liebherr’s expertise in gear cutting and gearbox design for its record breaking power gearbox, which is essential to increase the fuel efficiency of the aircraft engine. The gearbox is under development at Aerospace Transmission Technologies GmbH, a joint venture of Liebherr and Rolls Royce, in Friedrichshafen (Germany).