Material handling

Material handling

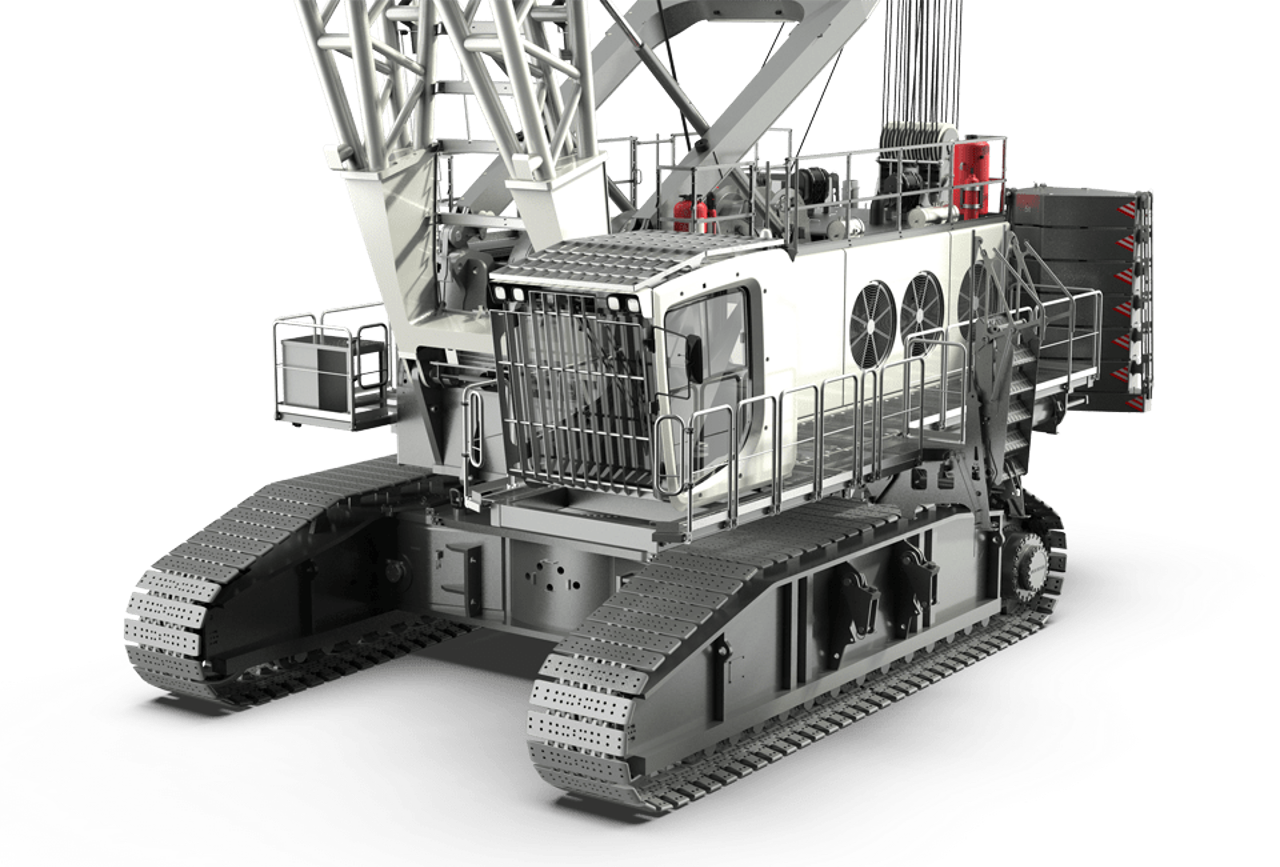

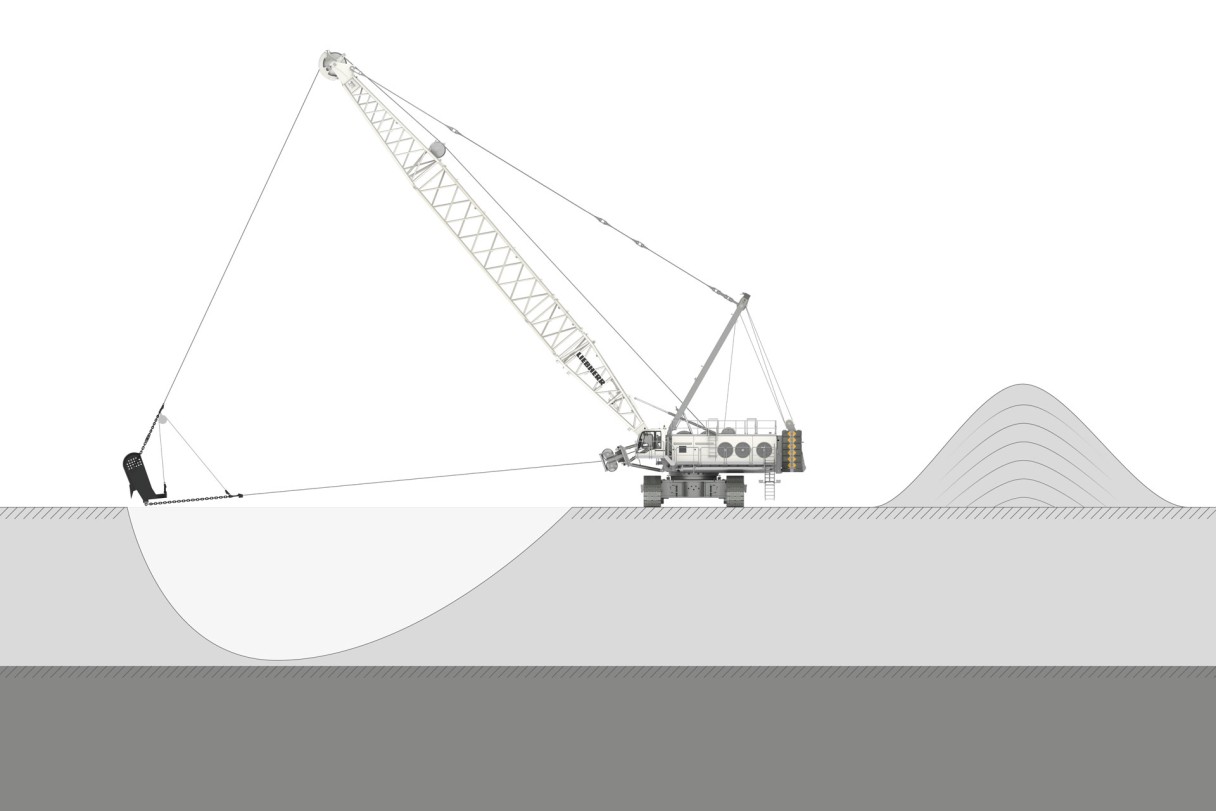

HS 8300 mining dragline

Performance

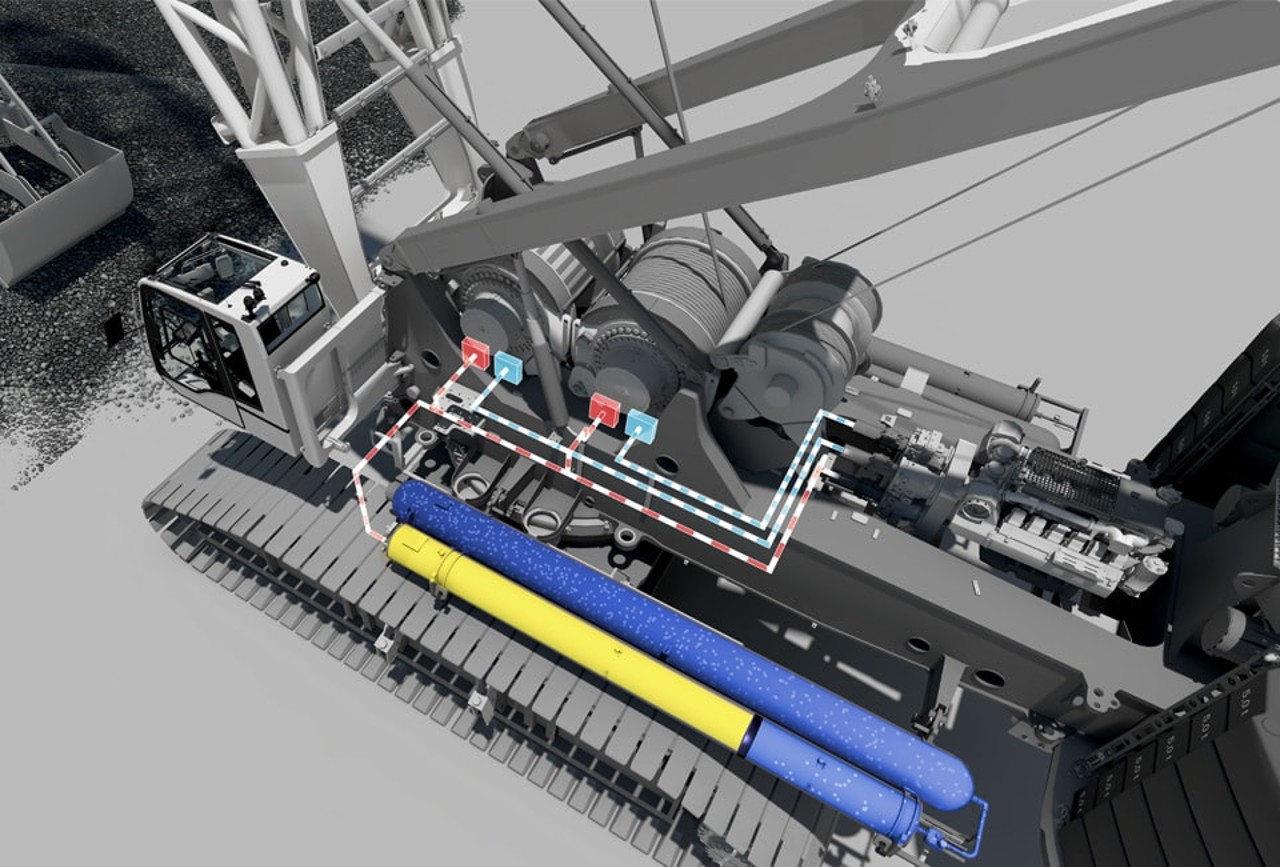

The mining dragline HS 8300 has been designed to meet the tough conditions in mining environments. The machine delivers power and performance with low cost per ton and high turnover rates. The interlock control system allows for power regeneration in dragline operation, reducing fuel consumption as well as wear and tear of the free-fall winch.

Weight

approx. 364 t

802,483 lbs

Drive

Liebherr V12

(induction engine available)

Power

1250 kW

1675 hp

with hybrid drive

Boom

up to 50 m

164 ft

Bucket

up to 11.5 m3

15 yd3

Pressure

1.56 kg/cm2

153.0 kPa

Design

according to

EN 474-1

and

EN 474-12

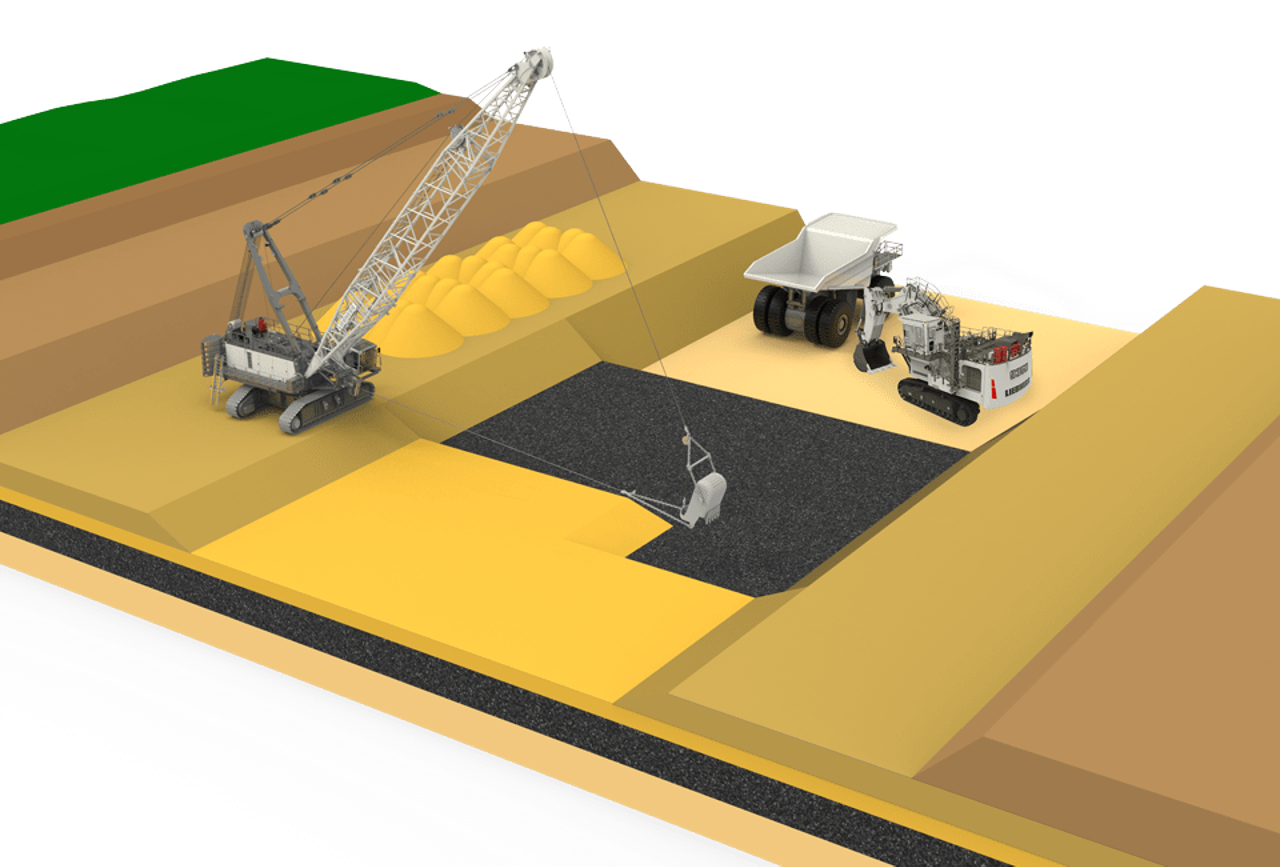

The dragline excavator

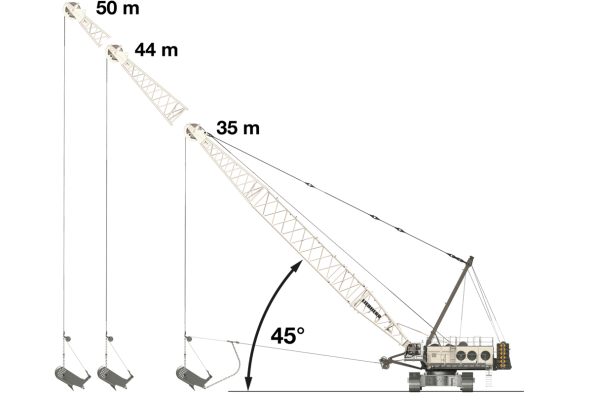

Digging ranges

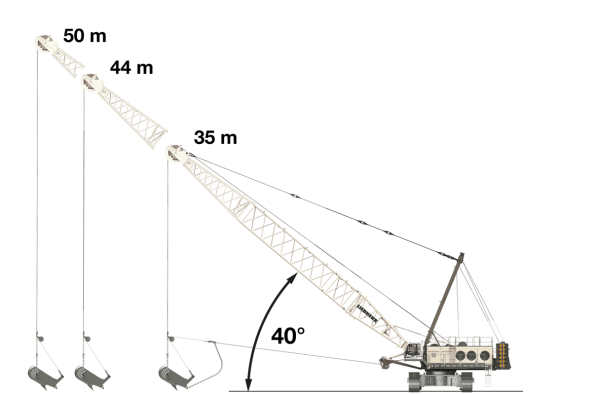

Digging and dumping ranges at 40° boom angle

at an assumed density of 1.6 t/m³ and a fill factor of 100 %

| Boom length | 35 | 44 | 50 | m |

| GP - General purpose bucket | 11.5 | 7.6 | 4.6 | m3 |

| HD - Heavy duty bucket | 11.1 | 7.3 | 4.2 | m3 |

| XHD - Extra heavy duty bucket | 10.7 | 6.9 | 3.8 | m3 |

| Load capacity | 30.0 | 19.2 | 11.2 | t |

| Digging/dumping reach* | 29.8 | 36.7 | 41.3 | m |

| Digging depth | 14.9 | 18.4 | 20.6 | m |

| Dumping height | 16.1 | 24.0 | 28.6 | m |

| *the reach is calculated from the rotation centre of the machine. | ||||

Limestone extraction

This video is provided by Google*. When you load this video, your data, including your IP address, is transmitted to Google, and may be stored and processed by Google, also for its own purposes, outside the EU or the EEA and thus in a third country, in particular in the USA**. We have no influence on further data processing by Google.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Sand quarrying

This video is provided by Google*. When you load this video, your data, including your IP address, is transmitted to Google, and may be stored and processed by Google, also for its own purposes, outside the EU or the EEA and thus in a third country, in particular in the USA**. We have no influence on further data processing by Google.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).