HLC series - Heavy Lift Cranes

Liebherr Heavy Lift Cranes (HLC) are specially designed for the installation of offshore wind turbine foundations and for the assembly and dismantling of offshore installations in the oil and gas industry. Depending on the customer's ship and application concept, Liebherr offers the best solution for worldwide offshore use with a wide range of cranes in the HLC series.

The HLC series benefits from Liebherr's high level of vertical integration. Numerous in-house components ensure smooth operation of these offshore cranes. Based on over 40 years of experience and constantly proven worldwide under the most demanding operating conditions, these components are characterised by the highest quality and long service life.

Strongest Liebherr cranes

Smart features & parts

Compact & versatile

24/7 global service

Rise of a giant

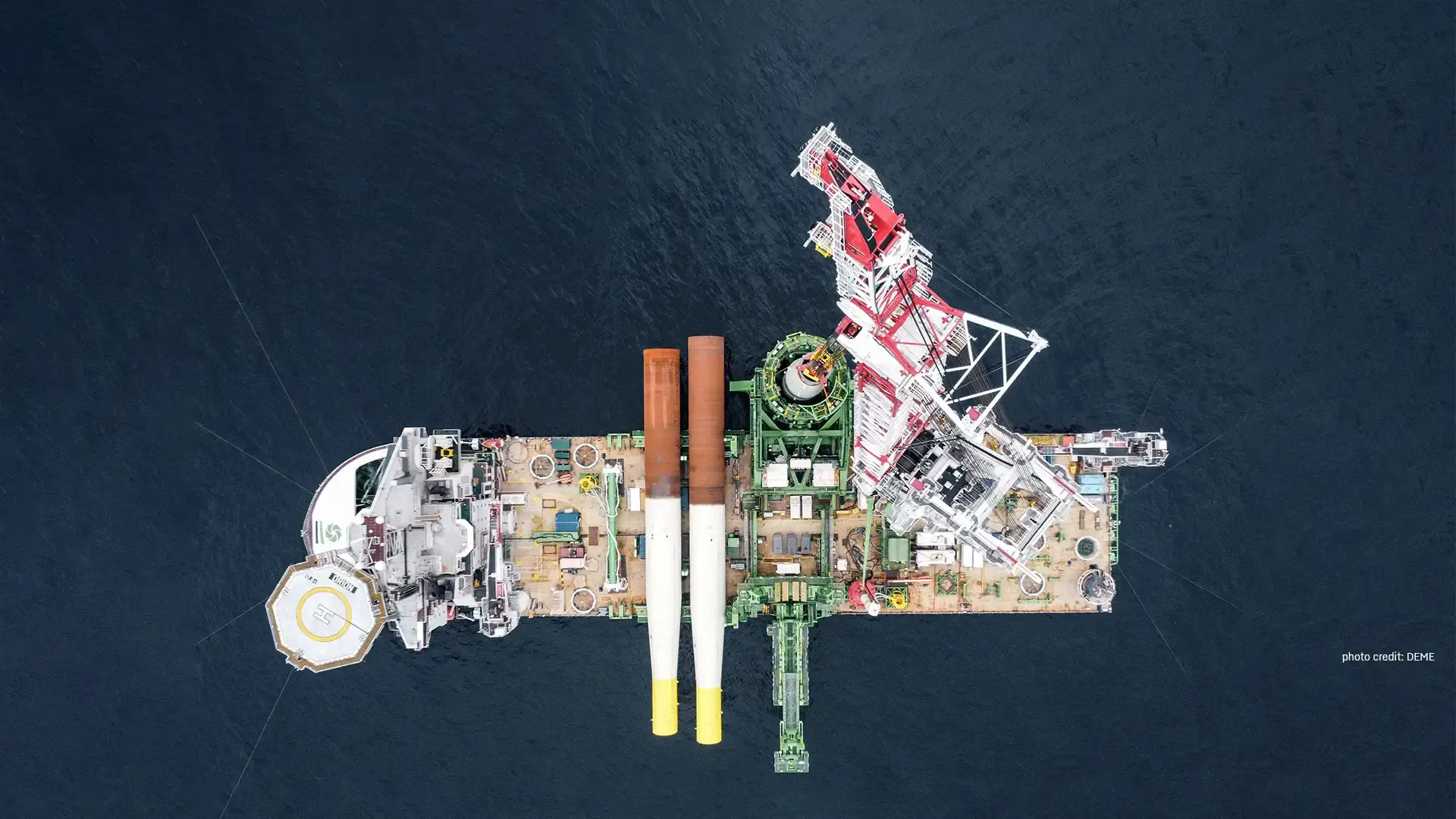

With a maximum lifting capacity of up to 5,000 tonnes and a maximum lifting height of 175 metres above deck, the HLC 295000 is the largest offshore crane Liebherr has ever manufactured. With this offshore crane and its modern technologies, the Orion is currently considered the most innovative vessel in the offshore wind industry. By dismantling the old and building up the new energy, the HLC series can promote the energy transition "at both ends of development" for a more sustainable future.

Your solution for:

Liebherr cranes working on both ends of the energy transition. Whether it’s an abandoned Oil & Gas platform or a jacket foundation at its end-of-life – the HLC is the ultimate tool to get rid of such residues.

Jacket foundations remain the means of choice when it comes to certain water depths or range of applications. With its outstanding hook height and remarkable lifting capacity even taller jackets are no problem for the HLC series.

Single platforms lifts or the stepwise installation of platform-components for the established O & G sector or for the rising Renewables are the characteristic domain of the HLC series. Those tasks are supported by its abundant lifting capacity and its very precise Litronic® crane controls.

When we talk about monopile installation, the HLC cranes feel “like a fish in the water”. Even the biggest monopiles do not really challenge the HLC series, considering all necessary operational steps from harbour loadout over the upending operation to the final transition piece installation.

Get in touch

- Trolley hoist

- Cabin

- Compact design

- Foldable A-frame

In order to move smaller loads as efficiently as possible, the HLC series can be equipped with one or more trolley hoists. The trolley rails of the Heavy Lift cranes are guided along the bottom of the main boom. In addition to the crane function, the trolley hoist winches can also be used as constant pull winches for load stabilisation. The hoisting rope of the trolley hoist is attached to the hoisting load and can be moved upwards with the hoisting load due to the travel capability of the trolley. This guarantees an optimum rope take-off angle to the hoisting load, so that it is optimally calmed down.

In order to move smaller loads as efficiently as possible, the HLC series can be equipped with one or more trolley hoists. The trolley rails of the Heavy Lift cranes are guided along the bottom of the main boom. In addition to the crane function, the trolley hoist winches can also be used as constant pull winches for load stabilisation. The hoisting rope of the trolley hoist is attached to the hoisting load and can be moved upwards with the hoisting load due to the travel capability of the trolley. This guarantees an optimum rope take-off angle to the hoisting load, so that it is optimally calmed down.

An enhancement for the energy transition

Offshore wind farms are being built more and more frequently to enable sustainable energy production. At the same time, ageing offshore oil and gas platforms are being dismantled. The HLC heavy duty crane series has been developed for both applications.

For the decommissioning of offshore oil and gas installations, there is a focus on dismantling as large parts as possible in order to reduce the need for flame-cutting works offshore as well as the overall number of necessary transport round-trips. With lifting capacities up to 5,000 tonnes and corresponding outreaches Liebherr's HLC series perfectly fits into that set of requirements.

Technical details

| HLC 295000 | HLC 150000 | |

| Max. lifting capacity | 5,000 t | 3,000 t |

| Max. outreach | 151 m | 84 m |

| Max. lifting height | 175 m | 121 m |

| Fly Jib capacity | up to 1,500 t | no Fly Jib |

| Base column | 16.8 m | 14 m |

| Slewing range | unlimited | unlimited |

Manufactured in Rostock (Germany)

Outstanding: The Liebherr global service-network

The Liebherr group provides a best-practice world-wide sales and service network. It’s Liebherr’s self-perception, that our dedication, care, and sense of responsibility as a leading crane manufacturer does not end as soon the crane has been handed over. The delivery date simply just marks the beginning of a long-term partnership. Whenever the customer needs the support of our remote technical advisors or our service engineers on the ground, they will be there.