How to: Customized gear skiving

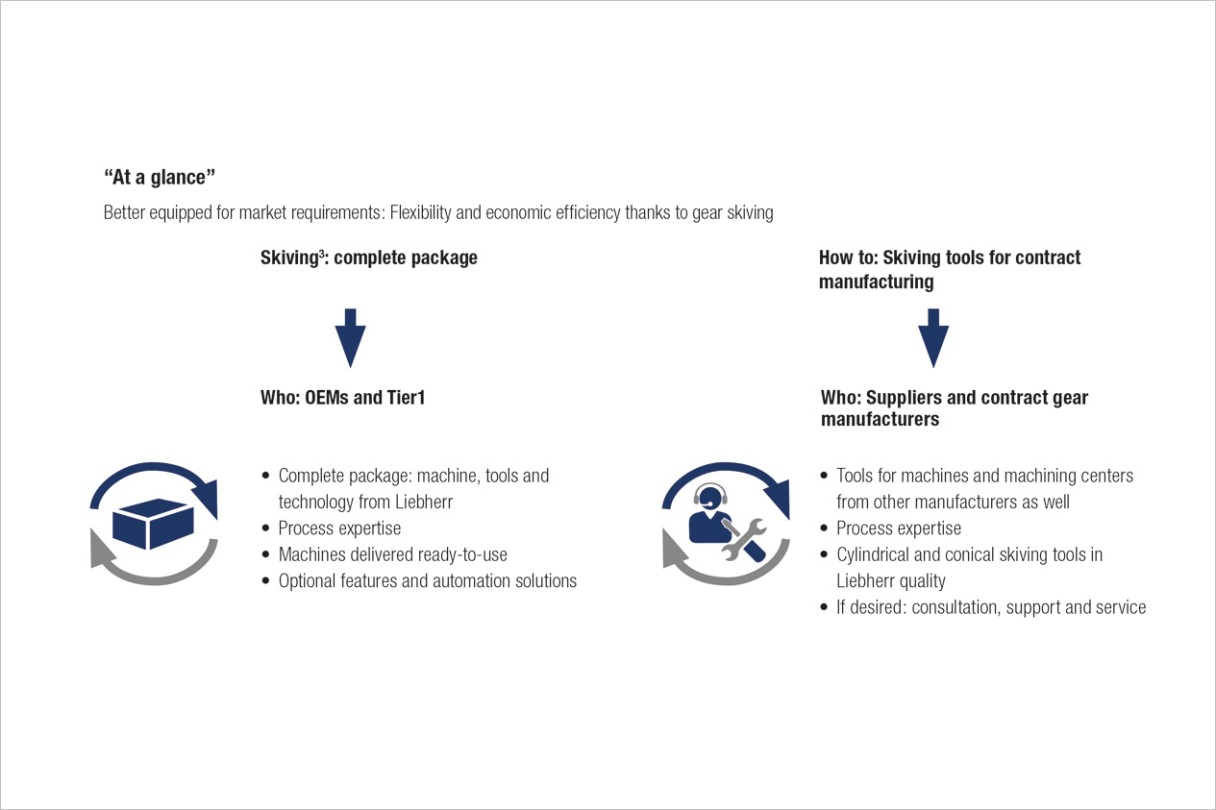

Gear skiving is over 100 years old and has recently been experiencing a renaissance as a flexible and economical alternative to other gear cutting methods. However, this complex process frequently presents great challenges to users. In addition to Skiving³, a “complete package” consisting of machine, tool and process, Liebherr now also offers skiving tools for suppliers and contract gear manufacturers – and the appropriate consultation, if desired.

Liebherr also offers skiving tools independently of the machines

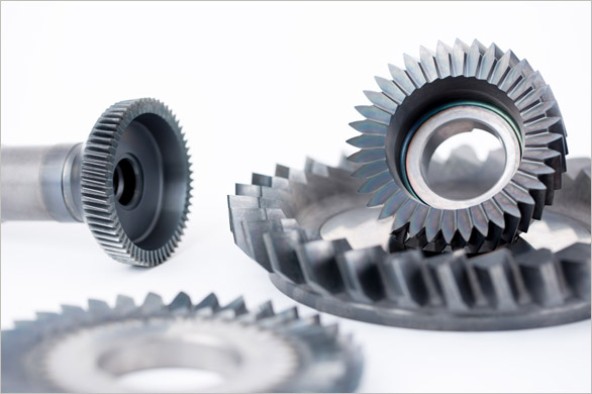

The almost forgotten method of gear skiving has again gained momentum through technological advancement. Modern, fast direct drives increase the cutting speed and therefore the productivity. Low-wear cutting materials and in-novative coatings ensure a long tool life. Gear skiving is considerably faster than shaping and, in many cases, more economical than broaching. The combination of crossed-axis angle, cutting speed, feeding and other kinematic parameters make the method very flexible: particularly for internal gears in medium batch sizes and external gears with an interfering contour, gear skiving is an additional “ace up your sleeve” in the gear cutting range.

Gear skiving doesn’t forgive any errors. Deviations in manufacturing tolerances often decide whether the machining will work or not. You have to know precisely which setting screws you have to turn.

It’s all about the process

So far, so good. Except that the highly complex process has to be mastered. The extreme dynamics and the complex axis arrangement demand a lot of the tool and make the method very challenging for users: “Gear skiving doesn’t forgive any errors. Deviations in manufacturing tolerances often decide whether the machining will work or not. You have to know precisely which setting screws you have to turn,” explains Dr. Oliver Winkel, Head of Technology Application. “We at Liebherr have taken the time and can justifiably claim that we understand the process.” If the customer buys a machine or tools from Liebherr, he is buying precisely this expertise and pro-cess reliability at the same time.

Economical in contract manufacturing as well

In times of fluctuating and generally decreasing batch sizes, gear skiving is also increasingly of interest to contract manufacturing – as a flexible and economical addition to the established gear cutting methods. However, many contract manufacturers shy away from investing in a new machine. An economical alternative is to use Liebherr tools on existing equipment. In Kempten, Liebherr uses an open concept and offers their own manufactured tools independently of the machines – with consultation on request.

Whether they are in the supplier industry or contract manufacturing, all customers ultimately want to be optimally equipped for future market requirements and to enjoy the benefits offered by gear skiving. With the tried and tested, comprehensive allround package Skiving3 and the open tool concept, Liebherr is a suitable partner for both groups.