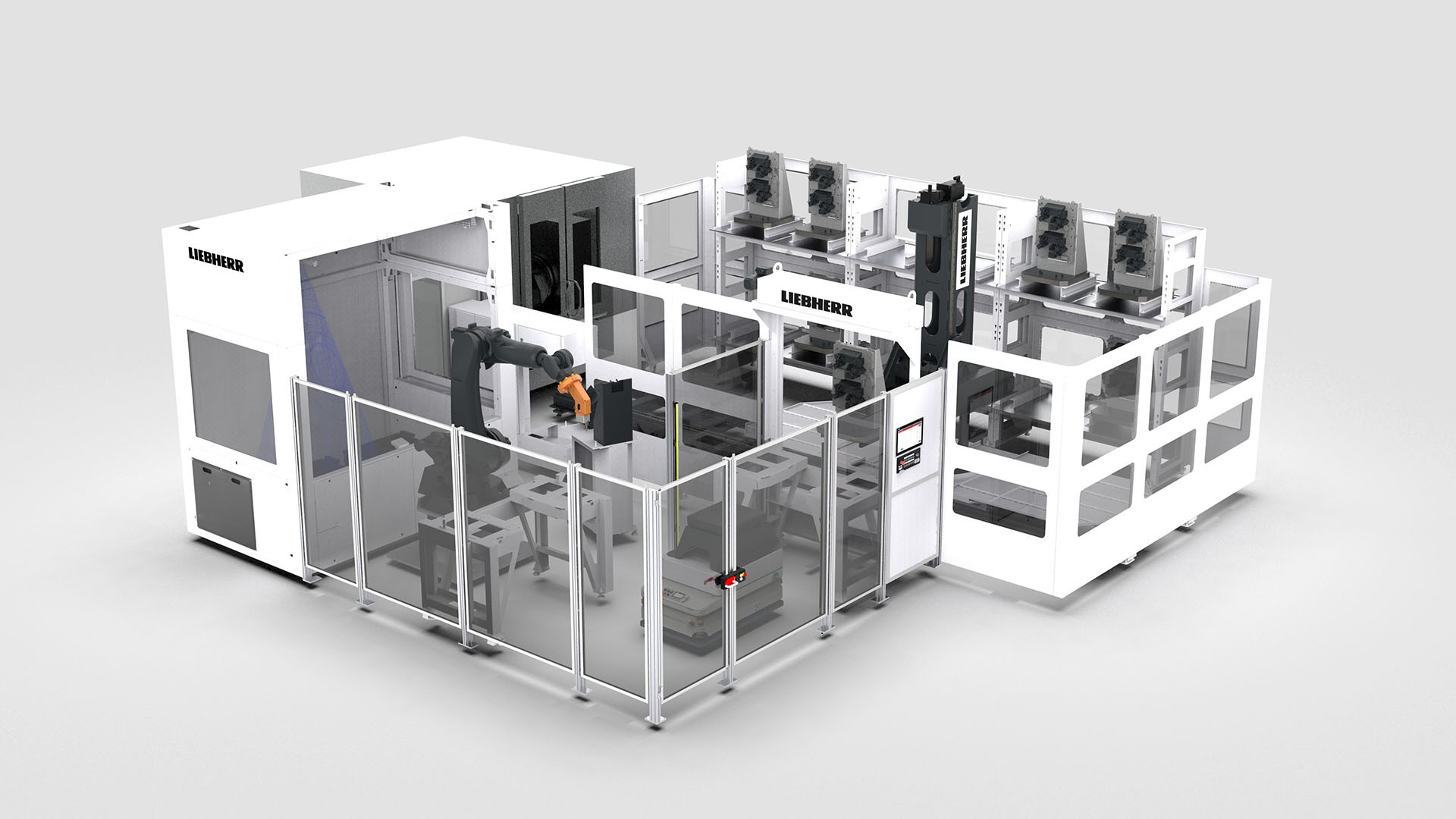

Flexible robot cells

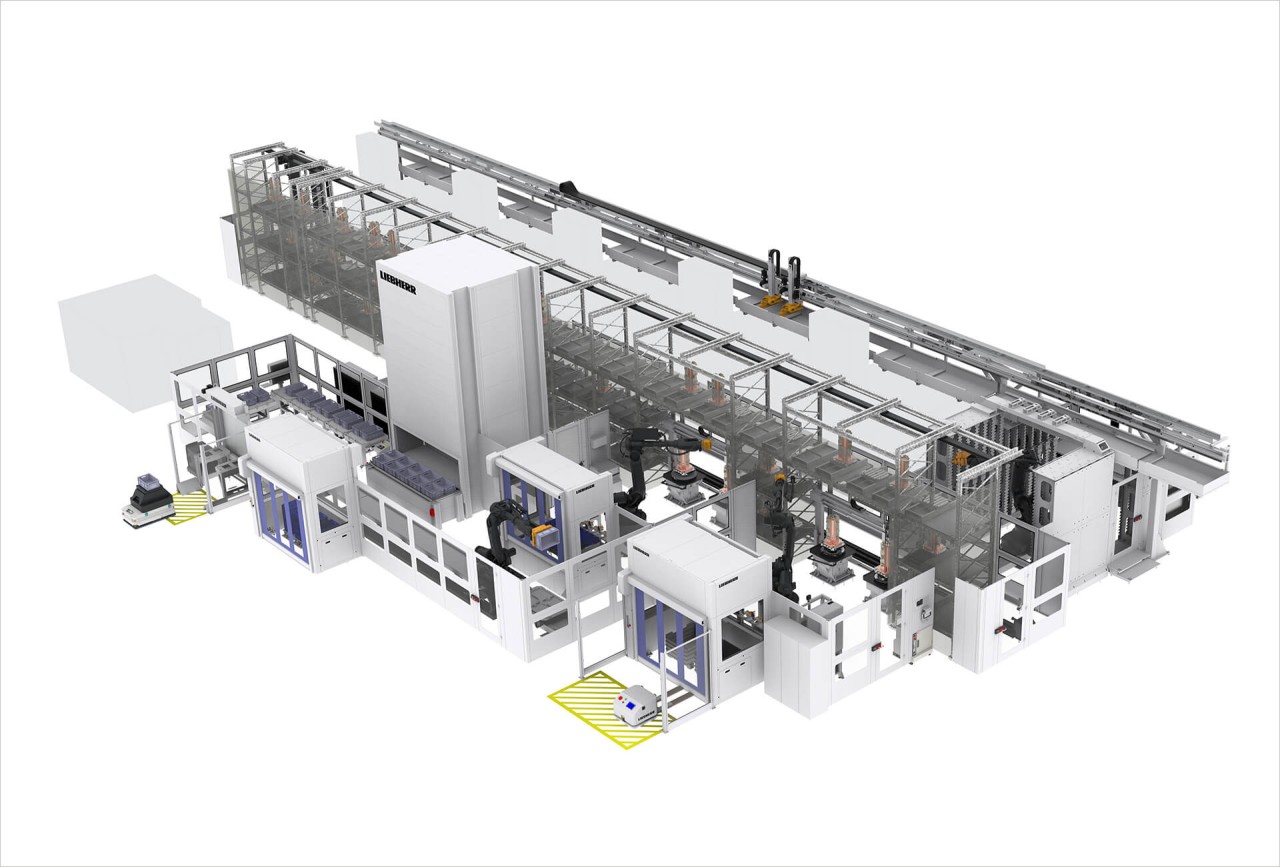

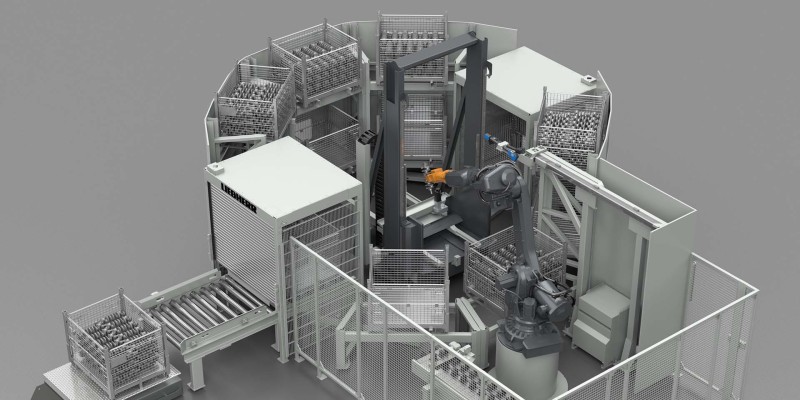

Liebherr automation for flexible production

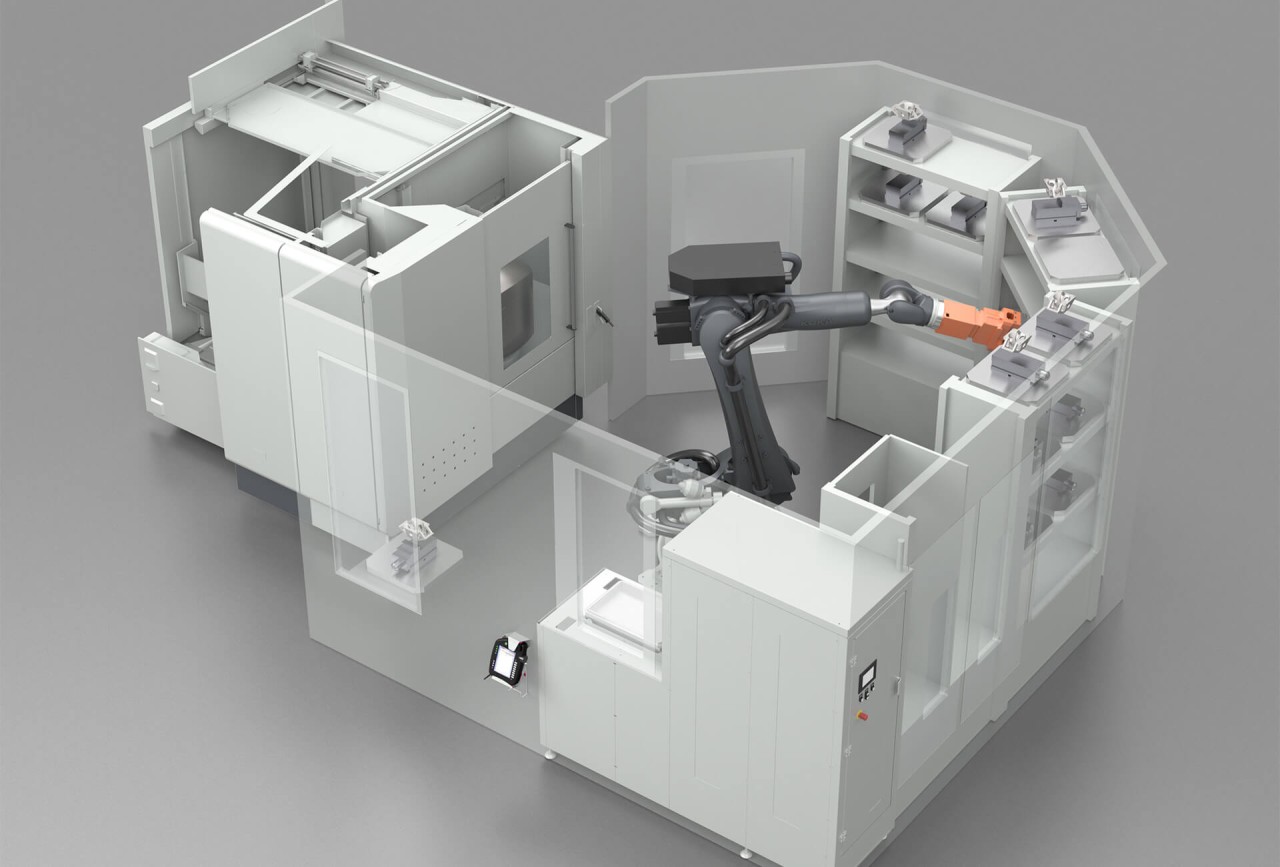

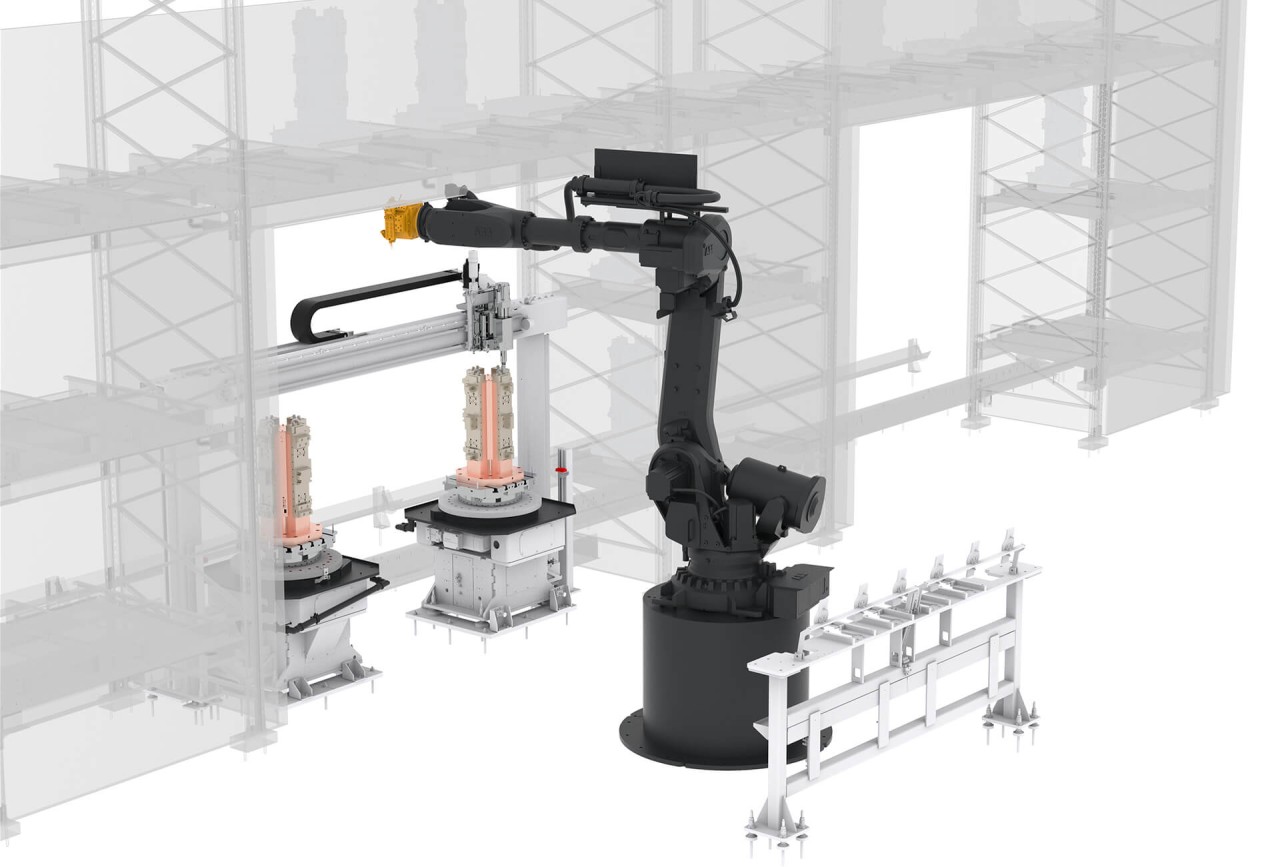

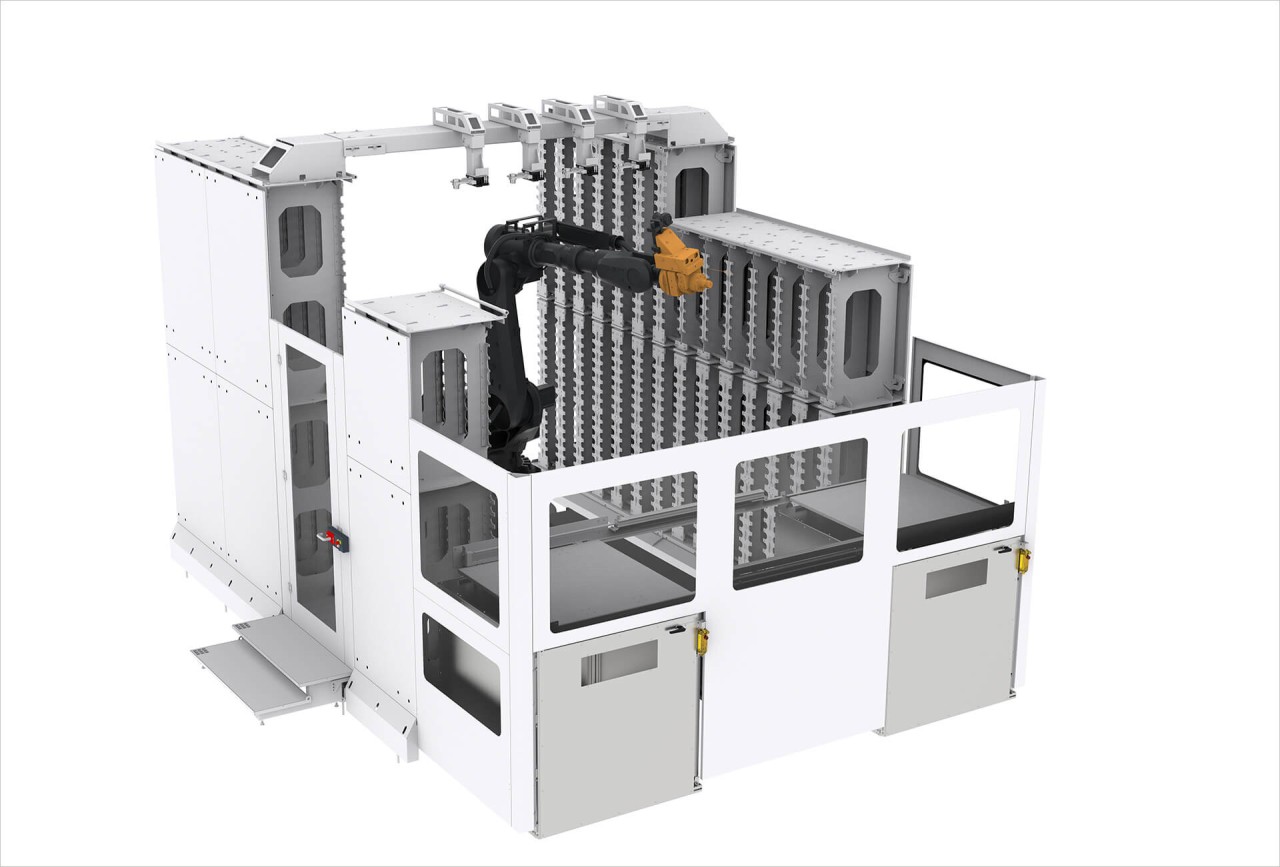

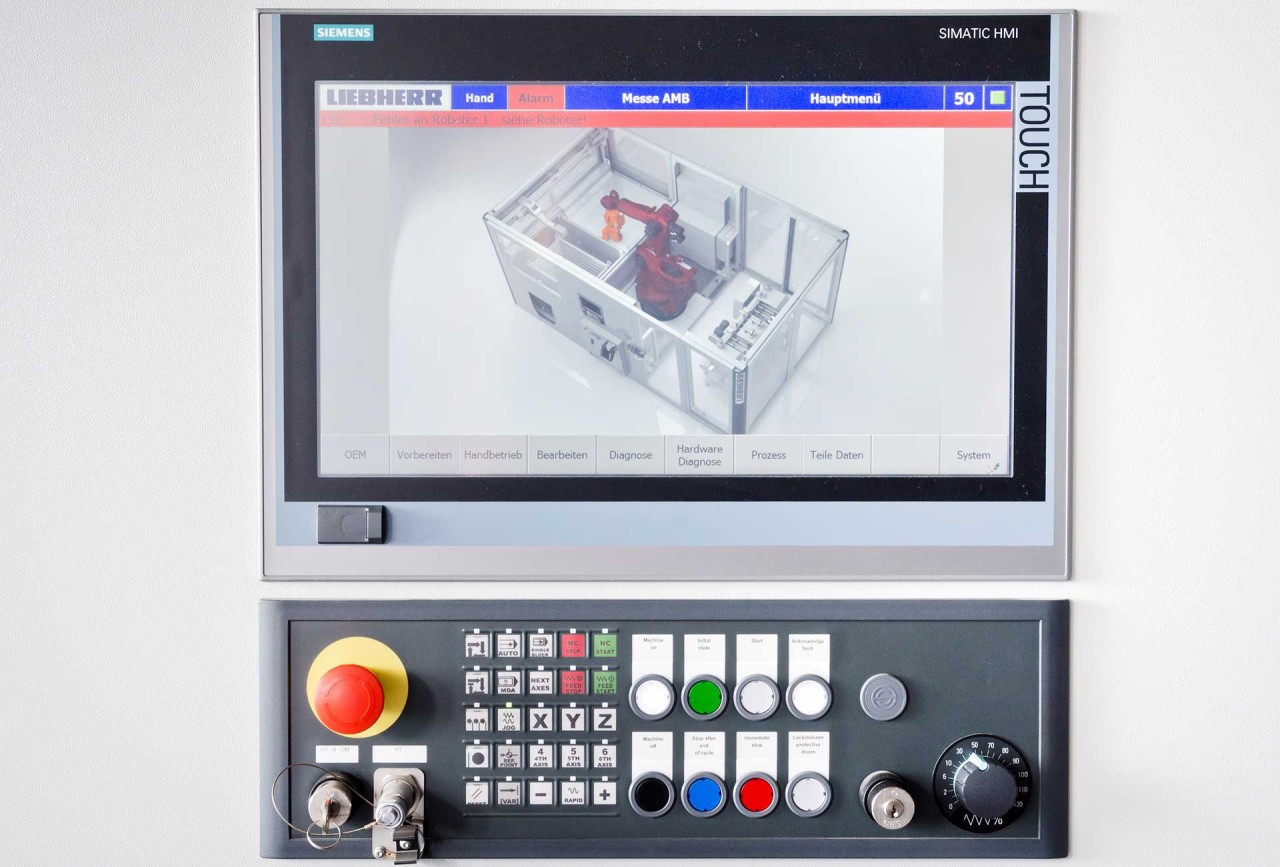

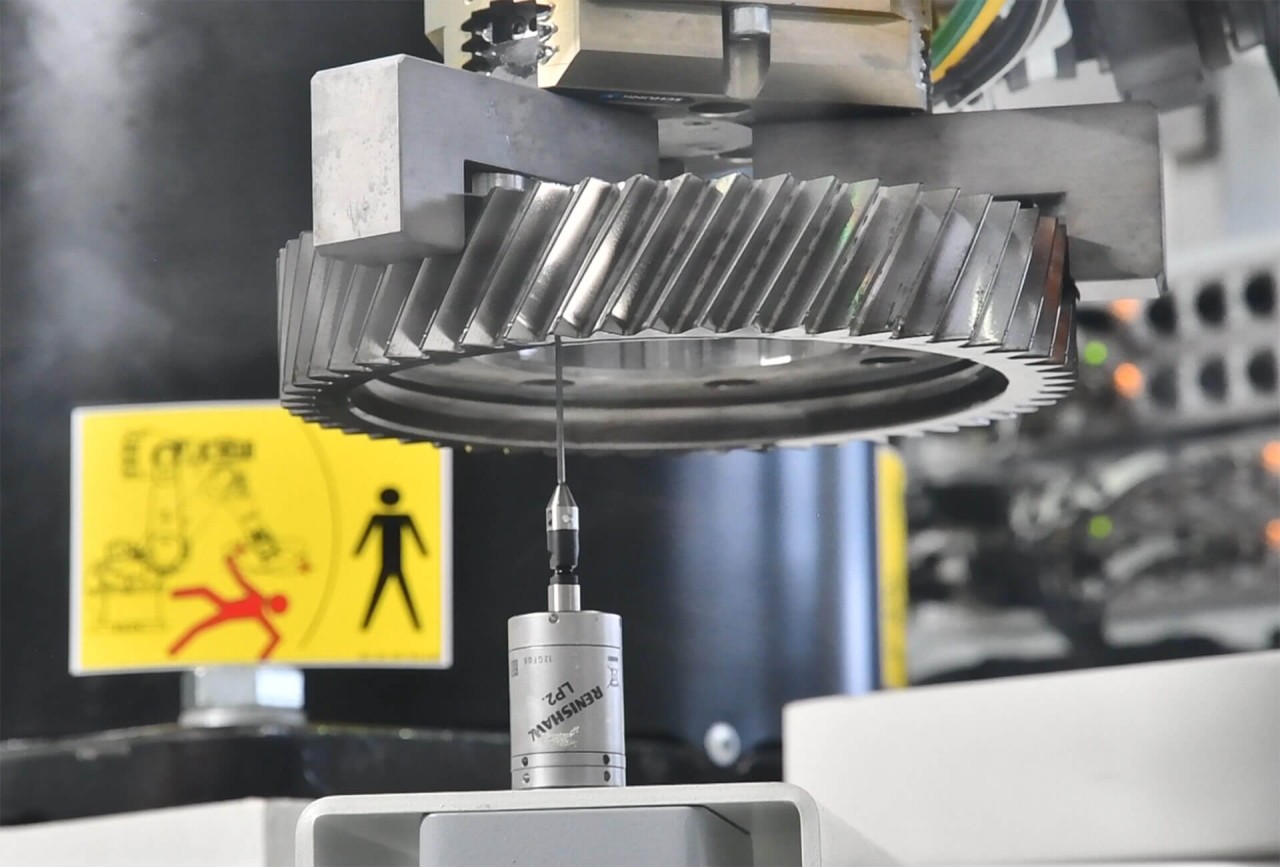

Automation is only suitable for large batches is a well-known myth but it only applies to production in rigid sequences. Flexible manufacturing systems with robot cells, on the other hand, can handle multiple part variants in different batch sizes. This makes them ideal for the production of small or medium-sized batches and enables alternative manufacturing concepts. In matrix production, processing steps are divided among manufacturing islands and are no longer tied to a fixed cycle. Production is more flexible and can compensate for fluctuations using buffer storage. This minimizes standstill times and maximizes productivity.

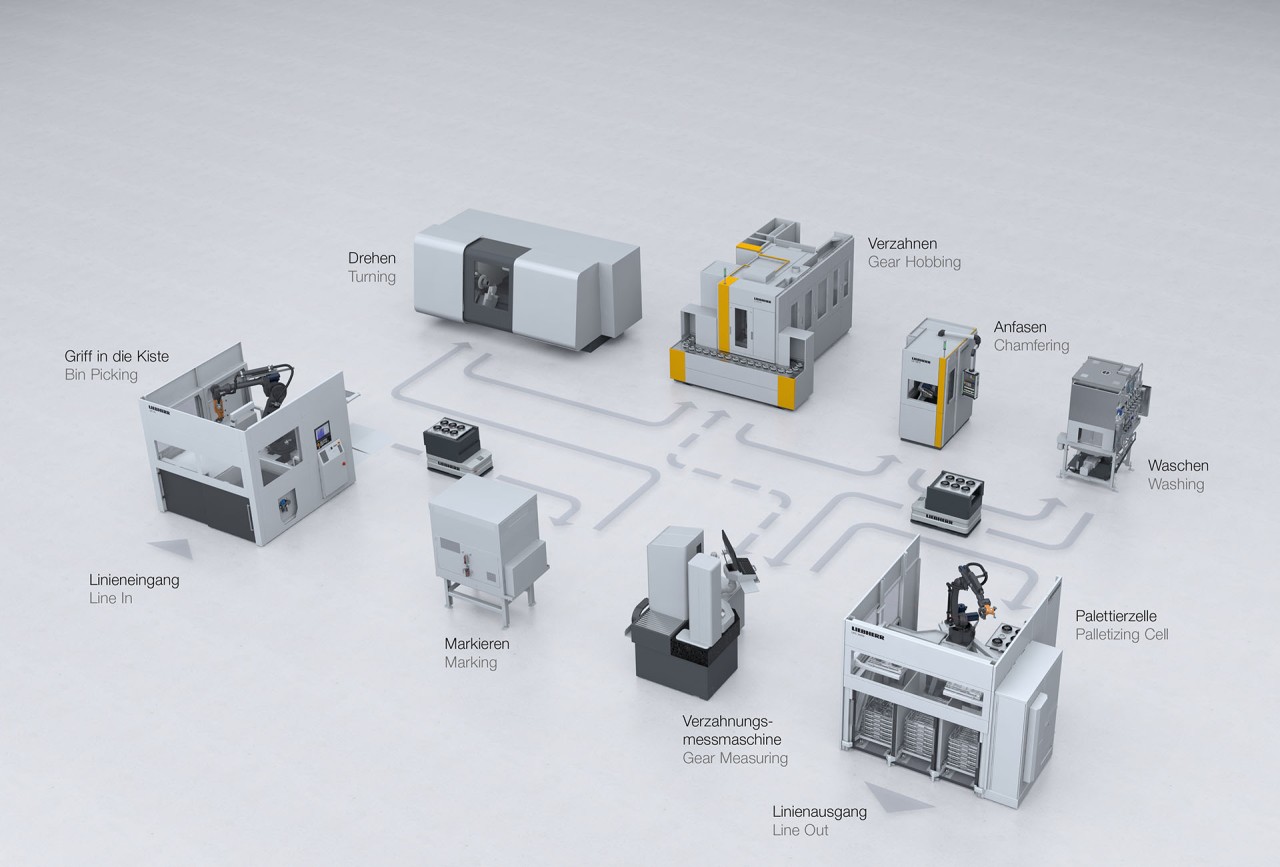

Practical insight: automated gear manufacturing

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Knowing beforehand how it will work afterwards

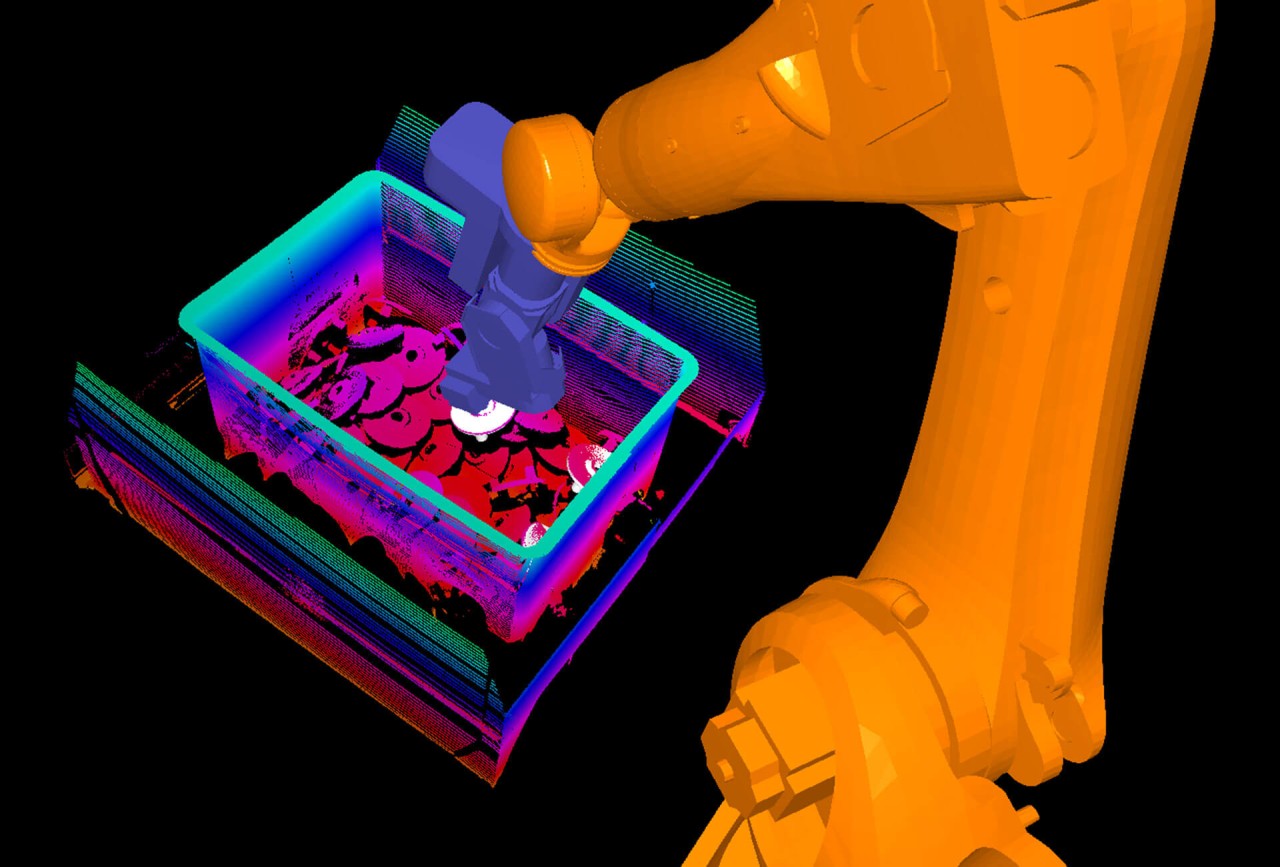

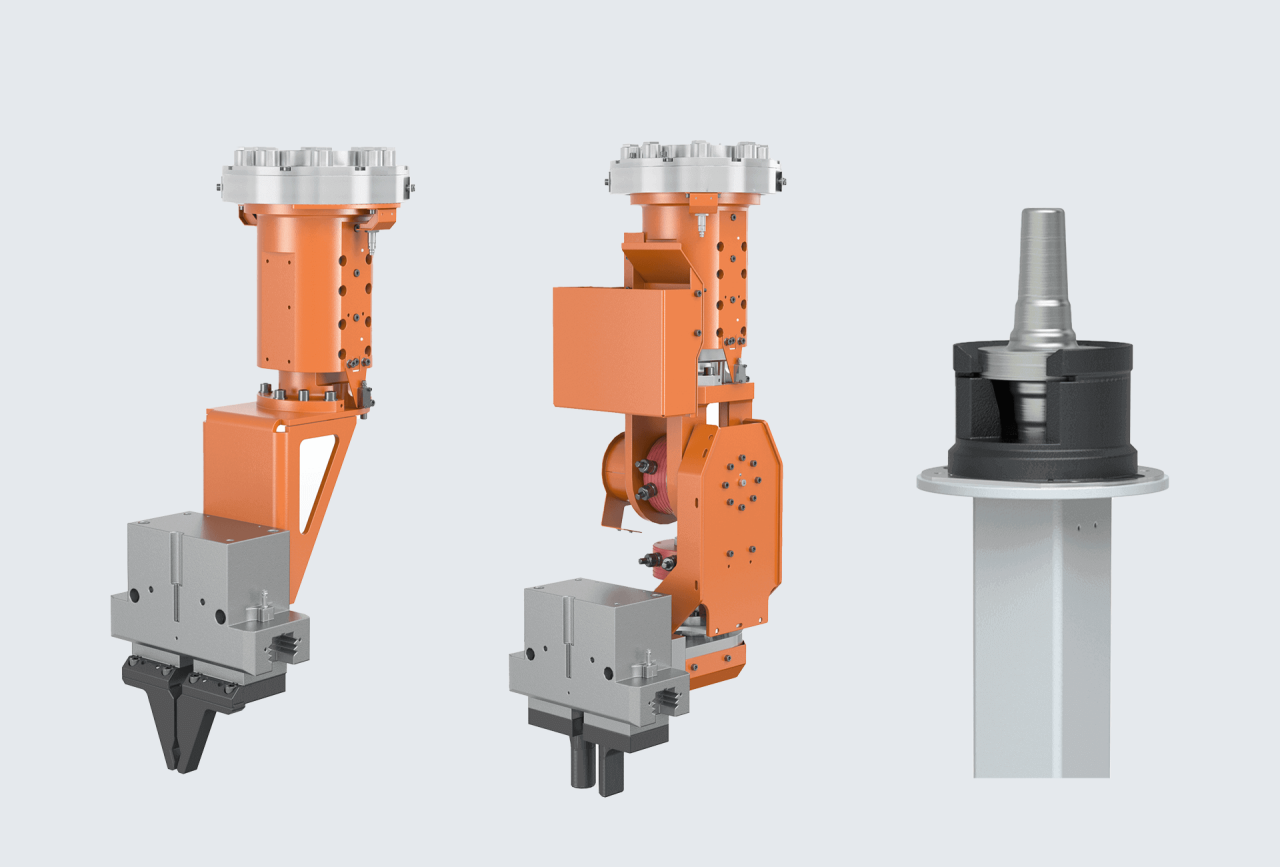

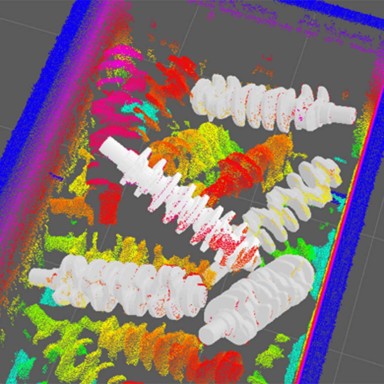

When it comes to automation projects, a certain amount of uncertainty is often involved. Are you implementing a particular cell concept for the first time? Do you lack experience in the application field? Do you have very tight cycle time requirements?

We can eliminate your project's uncertainties in advance with expert advice and comprehensive simulation offerings and know that it will work. We test reach and collisions, loads and gripping situations for every project. Decades of experience and testing capabilities at our customer center round off our portfolio.

Your contact for Flexible Robot Cells

We will be happy to answer your questions about Flexible Robot Cells.

Jürgen Groß

Sales Director Cells & Flexible Manufacturing Systems, Automation Systems, E-Mobility

Liebherr-Verzahntechnik GmbH

Kaufbeurer Straße 141

87437 Kempten

Deutschland

Tel.: +49 170 950 09 89

E-Mail

More information about flexible cells

Read exciting articles from our customer brochure