Automation solutions for mechanical engineering

Mechanical engineering

Markets have become more fast-paced. That's why we have to adapt to changing market situations at increasingly shorter notice in the interests of our customers.

Variety needs flexibility

Mechanical engineering is in our blood. From construction machinery to machine tools, Liebherr itself has been producing with a high level of vertical integration for more than 70 years. That's why we understand firsthand the challenges in mechanical engineering.

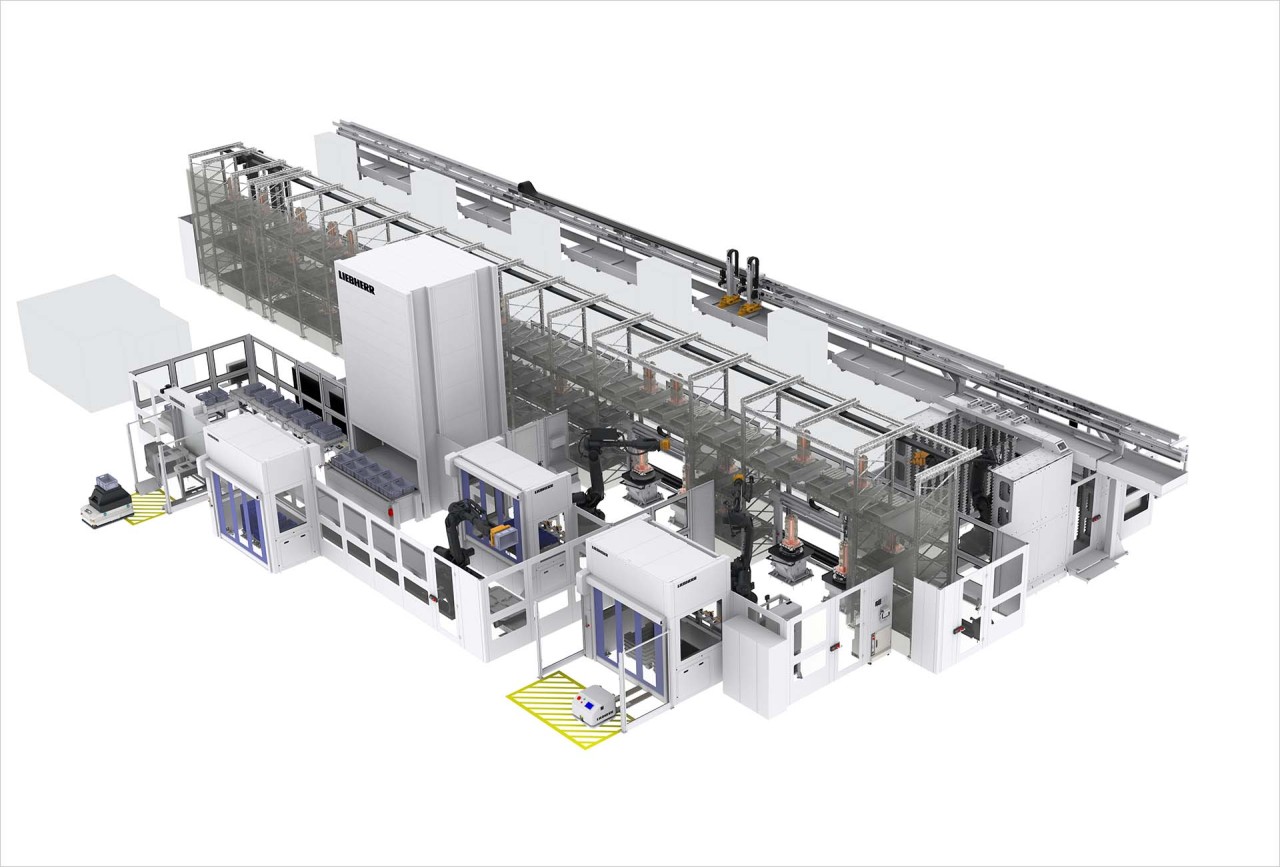

When it comes to automation, the number one requirement is flexibility. The large variety of parts makes intelligent automation concepts necessary: from series parts such as hydraulic cylinders to the variant-rich production of similar parts such as valve blocks to the small batch manufacturing of massive workpieces such as machine beds or components in steel construction.

To ensure that our automation fits this wide range of parts, we offer a broad product portfolio from a quantity of 1 to series production. If requirements ever change, we will subsequently adapt the capacity of your manufacturing system to the changed demand. Our goal is to advise you individually and deliver a solution that works exactly for you and your manufacturing processes. Top quality, maximum flexibility and costs under control our automation supports you in this.

Mechanical engineering: how to automate your manufacturing processes

Flexible robot cells

LHRobotics.Vision

PHS pallet handling systems

Video

Pallet handling systems: manufacturing from batch size 1

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).On our visits to Kempten, we were advised and taught about all the details and felt very well informed. Here it became apparent to us that Liebherr, as a long-established family business, is a reliable partner representing dependable and high-quality German mechanical engineering.

Flexible, error-free and low-maintenance - that's Liebherr.

Contact your sales partner:

By clicking on “ACCEPT”, you consent to the data transmission to Google for this map pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each Google map individually in the future and want to be able to load them without this blocker, you can also select “Always accept Google Maps” and thus also consent to the respectively associated data transmissions to Google for all other Google maps that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and thr Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).