Engineering partners for slewing bearings

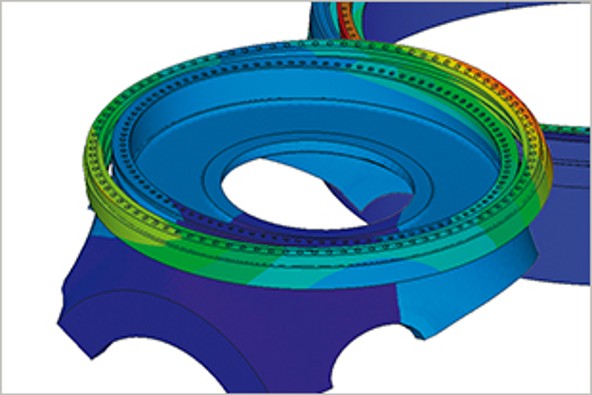

FEM calculation model for large diameter bearings

Competent design and calculation

An eye on all influencing factors: The optimal design and calculation of the components is decisive for the reliability and durability of Liebherr large diameter bearings. Every single bearing is therefore comprehensively checked and evaluated for specific requirements in the development and prototype stage.

Modern processes and methods

The latest construction processes, simulation methods, as well as quality management tools, are used in the design and calculation of Liebherr large diameter bearings. Our own calculation models round off the spectrum of methods. Application-specific criteria are always the focus of making the design a reality. Our customers benefit from our complex application expertise.

High level of vertical integration and professional know-how

Liebherr impresses with a high level of vertical integration when it comes to quality-related process steps. This ranges from the machining and inductive hardening of the bearing raceways to the gearing of large diameter bearings through to the surface coating in-house. Professional know-how and our modern machine fleet characterise the entire manufacturing process.

Manufacturing systems and production process

Contact

Please contact us – we will answer your questions and put together an individual offer for you. If you need a component as a spare part for your Liebherr machine, please contact your local service partner.

Contact

Regular audits and internal company standards

All corporate processes at Liebherr are focussed on quality, from the selection of raw materials and suppliers to the after-sales service. Each individual component of the large diameter slewing bearing is subject to strict quality requirements. This is why we only work with select suppliers, who are audited on a regular basis. Internal company standards apply to certain raw materials like rolled steel rings. These standards contain requirements, which go beyond the common industry standards.

Sophisticated quality management

Liebherr bearings are characterised by their high quality and reliability. In order to guarantee and further improve our quality standard over the long term, we document all manufacturing and assembly processes in a production data acquisition system. This also serves as a central quality management system for production and assembly measurements, thus allowing comprehensive control, monitoring and tracking; deviations are quickly eliminated and processes are constantly optimised.

Approved quality: certifications

The numerous certifications are testament to Liebherr's high standard of quality. Aside from the usual ISO standards of the quality management system, Liebherr has the following certifications:

- DIN EN ISO 9001:2015

This norm forms the basis for our QA system and the ongoing improvement process within the company Liebherr-Components Biberach GmbH for the business unit slewing bearings. - EN 1090-2:2008+A1:2011; EXC3 in accordance with EN 1090-2

This certification qualifies us to weld and produce steel support structures. These serve, for example, as earthquake protection in nuclear power stations.

Ultramodern measurement methods

Liebherr not only makes regular use of traditional computer-aided measurement methods. The Liebherr Group also possesses numerous highly specialised measuring devices. In recent years, for example, the company has invested in a state-of-the-art crack detection system using high frequency magnetisation and a fully climate-controlled large diameter bearing measuring chamber. 3D measurements of slewing rings with a diameter up to 6,000 mm can be effected. This type of measurement is unique worldwide.

Seamless quality management

Contact

Please contact us – we will answer your questions and put together an individual offer for you. If you need a component as a spare part for your Liebherr machine, please contact your local service partner.

Many years of collaboration with certification and inspection authorities

The certification and classification by internationally recognised certification and inspection authorities serves as an external quality certification for Liebherr. Classifications and certifications of components and complete systems are common in the area of maritime applications and in the wind industry. The Group looks back here on the many years of successful collaboration with classification companies.

Classification companies

We work with the following certification and inspection authorities, among others:

Certificates in accordance with EN 10204

The European standard EN 10204 defines various types of inspection documents and test certificates. Depending on the requirement of the test and documentation scope, we may provide various certificates in accordance with EN 10204 for the raw parts. Certificates in accordance with EN 10204 include:

For typical applications in mechanical and plant engineering:

- Certificate of Compliance 2.1

- Factory Certificate 2.2

- Acceptance Certificate 3.1

For special requirements:

- Acceptance Certificate 3.2

The classification companies require certain certificates within the framework of a prescribed classification approval. Upon request, Liebherr issues and supplies the necessary documents.

Contact

Please contact us – we will answer your questions and put together an individual offer for you. If you need a component as a spare part for your Liebherr machine, please contact your local service partner.

Wind industry

Liebherr supplies individual components, as well as the entire system for the rotor blade and yaw adjustment in wind turbines.

Contact

Wind industry

Liebherr supplies individual components, as well as the entire system for the rotor blade and yaw adjustment in wind turbines.