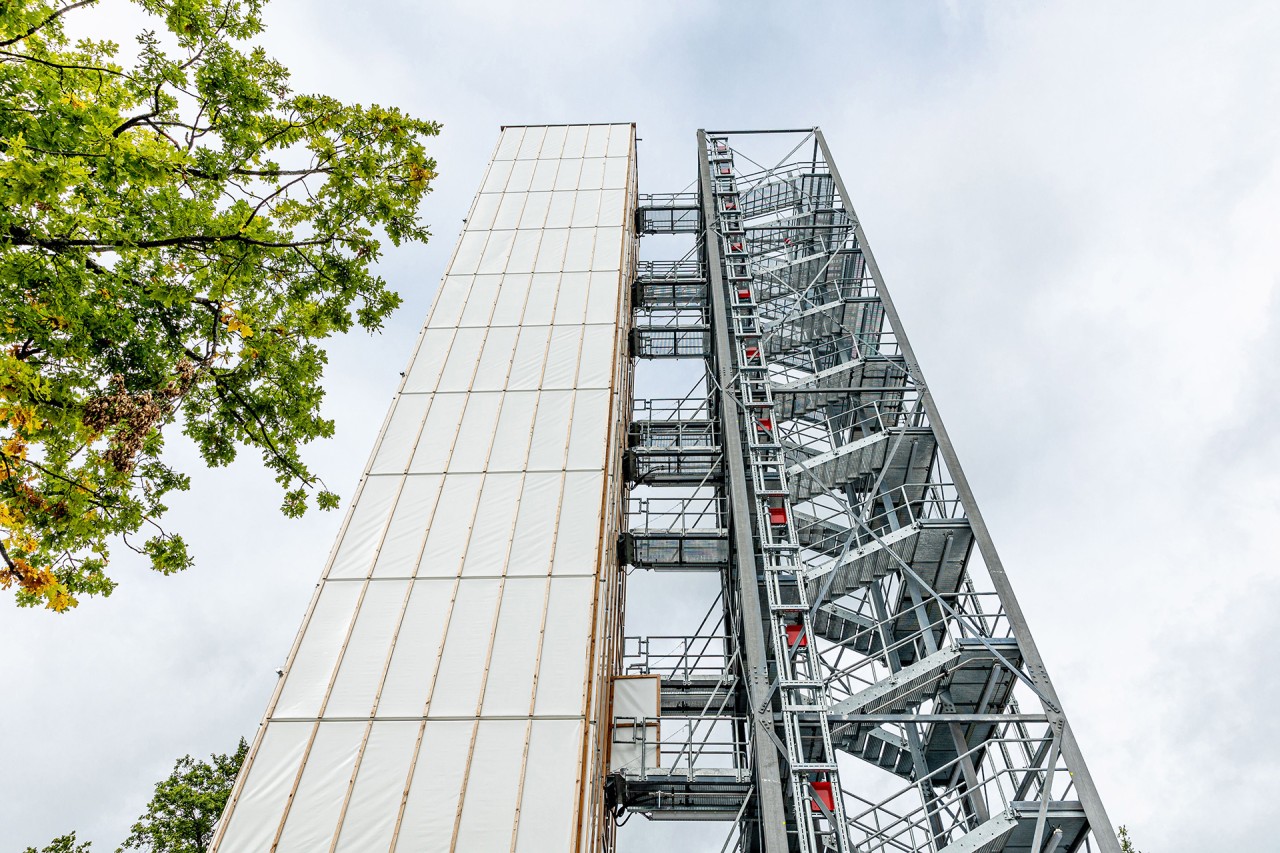

Projects, applications and success stories

By developing individual hydraulic solutions for a wide range of applications, we have been supporting our customers for years. Let yourself be captivated by our diverse stories and gain deeper insights into the world of our products.

01/02

01/02

Contact us.

We look forward to answering your questions and providing you with tailor made offers.

Fill in our contact form or get directly in touch with your contact person.

Are you curious to know more?

Stay in the know of other exciting topics and learn more about our products on LinkedIn.