Industria mineraria

Industria minerariaNews | 18.12.2024

Bringing innovation to life at Liebherr Mining

Before new products reach our customers, they need to be thoroughly tested. This is something that Lionel Oberhauser, group manager for the testing department at Liebherr-Mining Equipment Colmar SAS – our production facility for mining in Colmar, France – knows only too well. Working with these giant machines can be a challenge – but it’s a challenge that Oberhauser enjoys.

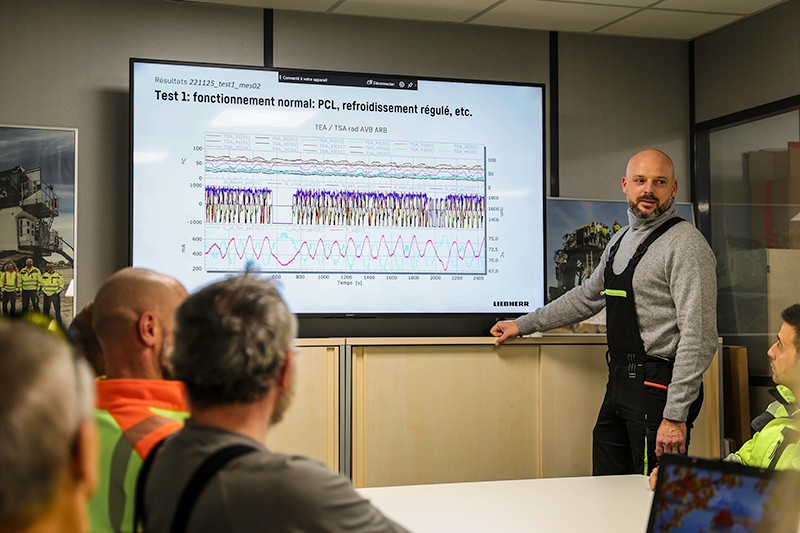

As a company, we strive for continuous innovation: our achievements today are the foundation on which we build the revolutionary ideas of tomorrow. But innovative ideas can only become innovative products with rigorous testing. The testing department within our mining production facility in Colmar, France, is responsible for making sure that our products can actually withstand the intense conditions of a mine site. As group manager of the testing department, Lionel Oberhauser oversees all of the validation tasks that come across his desk, coordinating each task with the members of his highly skilled team.

No two days the same

So what does a day in the life of the testing department look like? Well, it depends!

‘We can have very fast-paced days because of emergencies, or calmer days when we can carry out our planned tasks. Every day is different!’ says Oberhauser.

The testing department is made up of four test engineers, a workshop manager, three measurement and adjustment specialists and, of course, Oberhauser. The team uses its extensive product knowledge to define and fine-tune the parameters of an excavator prototype to ensure that the machine functions as the designers expect and is as productive and efficient as possible. They are also responsible for checking that components within subsystems, such as the cooling system, have been installed correctly. To do all of this fine-tuning and checking, the team conducts the relevant tests for each system and subsystem and then relays the collected information to the product development teams.

‘We regularly go out to our customers' sites and to Liebherr branches around the world to monitor machines in field tests, take part in troubleshooting or acquire data from the field,’ explains Oberhauser. ‘Our role puts us in contact with different players both in and out of Liebherr. That's what makes it such a rewarding job!’

The perfect fit

Oberhauser has been part of Liebherr Mining for nearly 14 years! He worked as a test engineer in the testing department for eight years before becoming group manager for the same team in 2019.

‘Applying for a job with Liebherr Mining was the best career decision I’ve made so far!’ he enthused.

The nature of the role was a perfect fit for Oberhauser; it allowed him to mix the theory he’d learned throughout his mechanical engineering studies with the practical skills he gained working as a structural design engineer for a company that manufactured car-carrying trucks. Plus, the work itself – overseeing the testing, validation and fine-tuning of Liebherr’s huge mining excavators – was a multidisciplinary and complex challenge that he thoroughly enjoyed when he first started and still enjoys to this day.

‘Although my title has changed, my job still involves handling test engineering tasks about 40 % of the time – which I love as this kind of job opportunity is rare,’ Oberhauser says. ‘When you work for the testing department, you must be able to talk to everyone as testing our excavators requires expertise in hydraulics, electricity, electronics, software and mechanics. Such collaboration is an important and fascinating part of my job.’

Accepting the role as group manager was a big challenge for Oberhauser, but one that he continues to enjoy to this day.

‘What’s great about my job is the feeling of having an active role in product development and customer satisfaction. Our machines are gigantic and technological monsters and we're the ones who validate them.’

The importance of teamwork

Having a team that he can rely on is a huge part of why Oberhauser enjoys his work. Even during times of stress, he knows that his team will always give their best. During one particularly challenging period, Oberhauser had to work out how his four testing engineers could manage the validation of seven different machines all at the same time. This was all while members of his team needed to make multiple trips around the world, some of which took them as far away as Australia and Indonesia! This not only represented technical, strategic and test equipment management challenges but also challenges in diplomacy.

‘In our work, we're facing the customer. We represent the image and quality of Liebherr Mining products both inside and outside the factory and it can be a lot of pressure,’ says Oberhauser. ‘But because the members of our group are motivated, trained and committed, we were able to navigate our way through this intense period. We know we can count on each other. It's priceless.’

Contacts

Liebherr Mining Equipment Newport News Co.

Newport News, VA 23607

United States of America