4 minutes | magazine 02/2021

Simply explained: remote control

Alexander Wirth, Product Software Developer at the Liebherr Plant in Ehingen, explains the Liebherr remote control.

Alexander Wirth - Product Software Developer

Liebherr remote control – from 30 to 3000 tonne cranes

What has been standard on tower cranes for decades is now becoming ever more established on mobile cranes as well – remote control from outside the crane cab. The benefit is obvious – the crane operator selects the location from which he has the best view of the site. This means greater safety, more comfort and easier communication on site. The introduction of the second generation of the LICCON control system around ten years ago enabled us to make the remote control of our mobile and crawler cranes particularly comprehensive and economical – the same control system for cranes between 30 and 3000 tonnes. Alexander Wirth has been working in the crane control department at Liebherr in Ehingen for 15 years. He explains the technology behind it.

Most crane manufacturers install a remote control system from a third party supplier. We did the same thing in the past. But then two different systems have to communicate with each other and the remote control functions are limited. It is difficult to make adjustments and add functions.

The remote control we have developed in-house makes us ready to face the challenges of the future.

Our LICCON2 control system took a completely different approach – the remote control is an in-house development. That also means that its ongoing development is also completely in our own hands. And that has already proved to be a good thing.

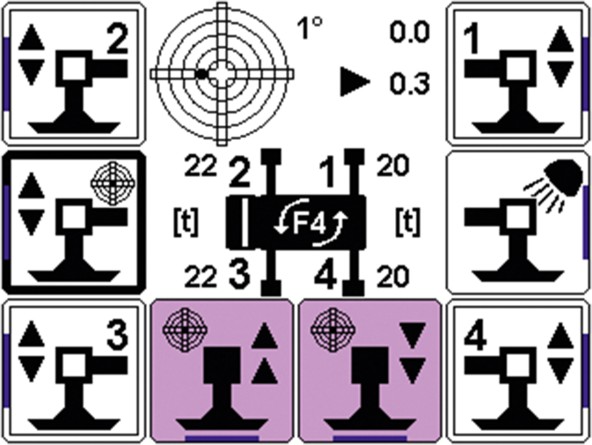

The new and unique feature for mobile cranes was that all the cranes with the new control system were supplied with a remote control for setting up the crane as standard – using a hand-held control console, the BTT, the crane operator can extend the crane’s outriggers, attach the hook block to the bumper and larger cranes have more functions, such as attaching the ballast or installing the telescopic boom. And all of this work is carried out in the operator’s direct line of sight – safely, quickly and conveniently.

RemoteDrive: Manoeuvring the crane chassis on constricted sites with excellent visibility

Supporting with fully automatic levelling

The BTT, featuring a display and function keys, makes it possible to level the crane fully automatically, start and stop the engine and adjust the engine speed remotely. The telescopic boom, hoist winches and the axle suspension on the crane can all be controlled using the BTT. Many crane operators first had to get used to this new luxury, but very few of them would want to set up a crane without the remote control these days.

And now we come to the real highlight of Liebherr’s remote control system – you only have to buy a single BTT-E, a console with two master switches, and you can control every LICCON2 crane in your fleet by remote. For several years now, we have been installing the software for complete remote control in all our cranes which feature the LICCON2 control system. You cannot control mobile and crawler cranes remotely at a lower cost! The system will work on all cranes from the small LTM 1030-2.1 to the gigantic LR 13000. All crane movements can be controlled economically and conveniently from outside the cab with clear lines of sight and close to the load.

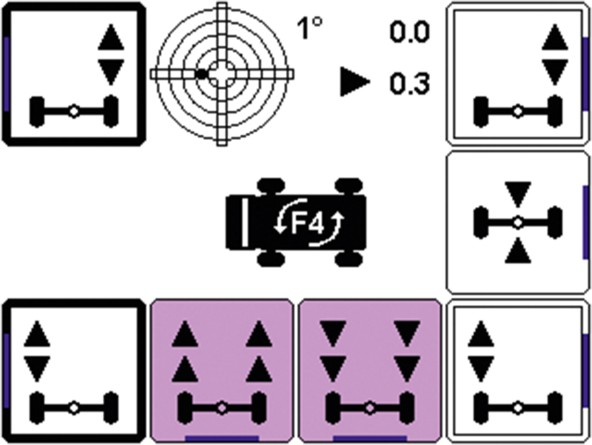

Convenient control of the axle suspension

It is now also possible to control the crane chassis remotely on the compact LTC 1050-3.1. Using RemoteDrive, the operator positions himself in the problem area to manoeuvre the crane safely through constricted areas. Several additional components are required in the drive system for this new option, but it also works using exactly the same hardware, the BTT and BTT-E control consoles.

And there is another major benefit, particularly when it comes to selling a used crane – because we decided to use a globally licensed frequency range (ISM band 2.4 GHz), our system can be used in every country in the world.

This article was published in the UpLoad magazine 02 | 2021.