Mobile and crawler cranes

Mobile and crawler cranes

4 minutes - magazine 01 | 2023

EN 13000

A few years ago, when all the crane manufacturers in Europe had to remove the key switch to bypass the overload system, the subject of the EN 13000 standard was suddenly on everybody’s lips.

Standard compliance

All our load charts stated that they had been calculated on the basis of EN 13000. So what exactly is EN 13000 and how does this standard affect our crane design work? Head of Design Bernd Boos, who himself actively plays a part in writing standards, explains the situation.

Product safety in Europe is regulated by a wide range of directives. These directives are implemented as laws in the member countries of the European Union, making them mandatory. The directive which particularly affects us as a crane manufacturer is the Machinery Directive 2006/42/EC. This defines the basic requirements for the safety of machines, starting, for example, with hand-held drills and extending right up to our mobile cranes.

Bernd Boos - Head of Design Telescopic Cranes

A specific section of this directive deals with the hazards resulting from hoisting processes and formulates the special requirements for everything to do with hoisting work. Even in this section, the requirements are formulated in very general terms as it covers all hoisting gear, for example, a manual chain hoist with a lifting capacity of 750 kilograms up to a crawler crane with a lifting capacity of 3,000 tonnes.

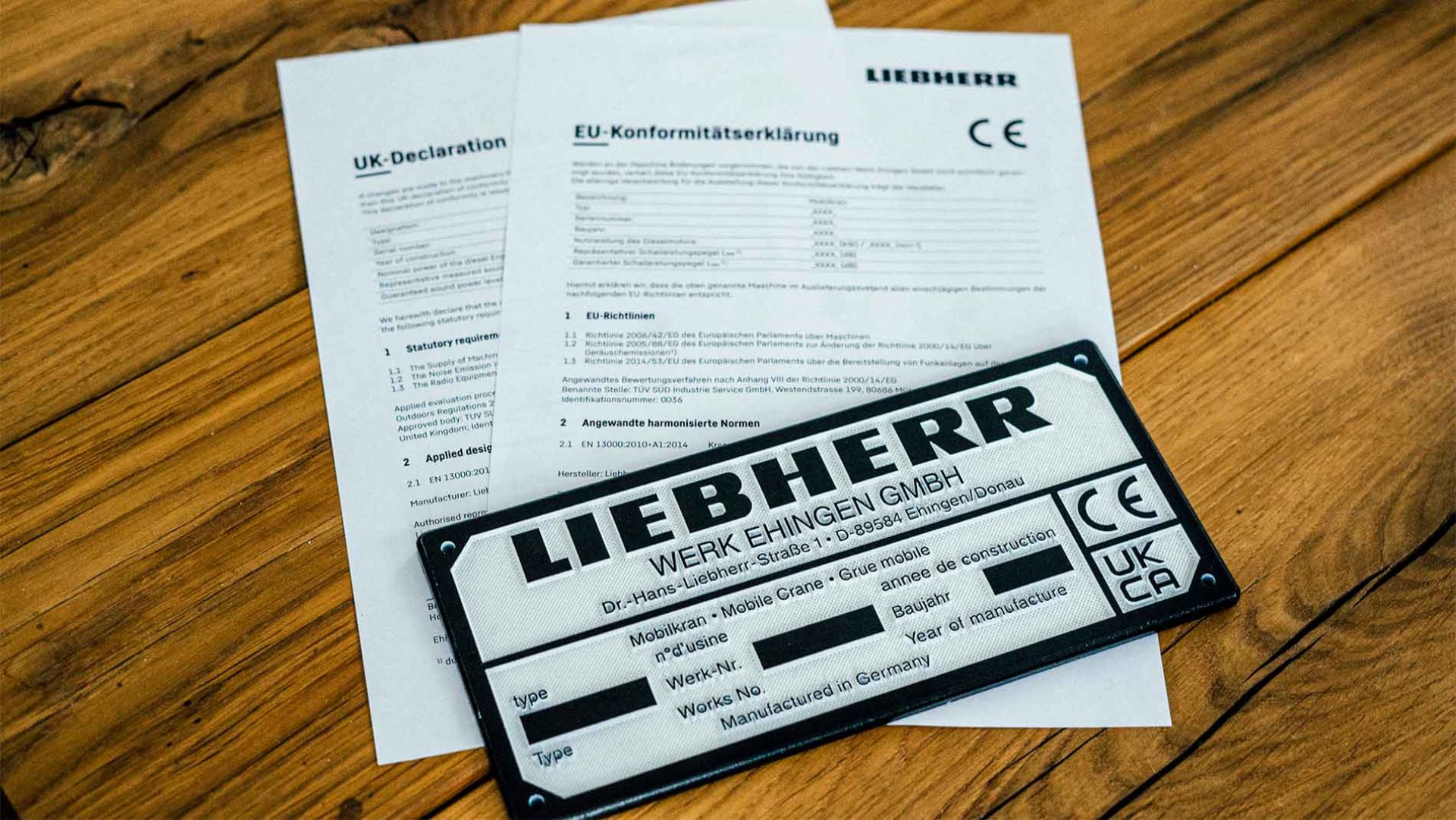

To flesh out these general requirements to suit specific products, they are formulated in European product standards. For us as a mobile crane manufacturer, the relevant standard is EN 13000. When a European standard is harmonised, in other words when it is officially published in the Official Gazette of the European Union, conformity is assumed by the application of the standard. In other words, if the EN 13000 product standard is used, we as a manufacturer may assume that we are complying with the Machinery Directive and therefore the law. We confirm compliance with European directives with the CE mark on the machine tag and the EU declaration of conformity which forms part of the crane documentation. In addition to the Machinery Directive, we also use the CE sign to confirm compliance with noise emissions and the Radio Equipment Directive.

EN 13000 was first published in 2004. All products from the Liebherr plant in Ehingen, in other words LTM, LTR, LTC, LTF, LRT, LR and LG cranes, are covered by this product standard. MK cranes for which we supply the chassis, on the other hand, are covered by the tower crane standard EN 14439.

The current version of the standard is EN 13000:2010+A1:2014. The basis of this version was published in 2010 and has been in force since 2012. One of the aspects of the 2010 version was the ban on the key switch in the LMB from the cab, in other words the situation that we know today. The amendment dated 2014 (A1:2014) then also added the outrigger width monitor in the form of warning.

Both the Machinery Directive and EN 13000 are currently undergoing revision. The publication of the new Machinery Directive, which we expect in short term and will also result in a regulation, which will place new requirements on us as a manufacturer. These requirements will then have to be fleshed out in detail in the next version of EN 13000 for mobile cranes. Some of the requirements from this version have already been implemented at Liebherr, for example the identification of counterweights on telescopic cranes, the outrigger width monitor with a shutdown facility and the support force monitor.

At Liebherr-Werk Ehingen GmbH, we play an active role in creating the EN 13000 product standard. Whilst I work on the standard committee as a whole, some of my colleagues work in the structural engineering and crane control expert groups.

This article was published in the UpLoad magazine 01 | 2023.