9 minutes - magazine 02 | 2023

Into the future with green concepts

The energy transition is moving forward, climate protection is on everyoneʼs lips. And we are helping to shape the change.

Reducing our heat demand is crucial.

How environmental protection and crane production work in harmony.

Whether through our products, in plant traffic or in building management – there are many small and large examples of environmental protection at Liebherr in Ehingen.

By 2050, renewable energy sources such as hydroelectric, solar power, geothermal energy and wind energy as well as renewable raw materials should account for around 60 per cent of gross final energy consumption and 80 per cent of gross electricity consumption in Germany. In order for the energy transition to be successful, the Federal Ministry of Education and Research also aims to oversee a significant increase in energy efficiency. Among other things, this involves energy-efficient building renovations and energysaving industrial processes.

Areas in which savings are being made:

– 43,000 metres of geothermal energy installed since 2006

– Approx. 160,000 m² of lighting converted to dimmable LED technology

– 30 % reduction in the power consumption of the LED technology due to proprietary daylightdependent control systems

– 70 % heat recovery in the paint shop and exhaust air systems

– 67 % heat recovery from extraction systems and compressed air systems

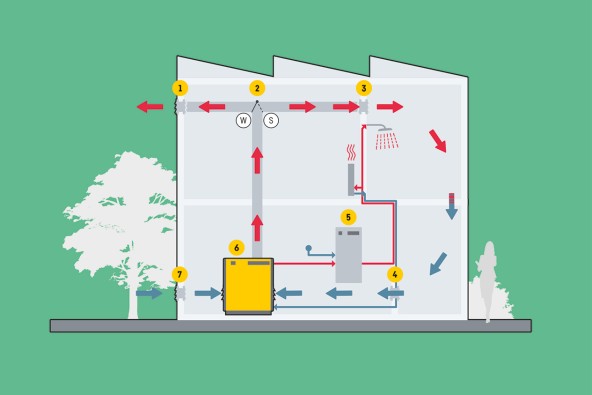

“We are seeing a constant stream of new proposals and ideas from the legislator and new regulations are being issued. However, we have been developing our own environmental protection measures for many years and have already made significant progress in terms of protecting the environment, saving energy and, of course, costs,” says Jürgen Abele, Division Manager for Industrial Services and Construction. One area of focus is heat supply, which is not only about ensuring pleasant temperatures in office buildings and production halls: “We are developing concepts that optimise the way we generate and use heat, among other things,” he explains. Abele and his department are therefore in charge of a versatile heating system: the heat is generated using geothermal and solar thermal energy, for example, or recovered by heat pumps and heat recovery equipment installed in the compressed air and exhaust air systems. The conventional natural-gas-fuelled radiant heaters and burners are operated via temperature or cascade controls, which can limit their consumption and thus lower the demand on the natural gas grid. “The key factor is reducing heat demand,” adds Energy Engineer Sophie Gantert: “The production buildings have therefore been continuously renovated over the years and the roofs and façades have been insulated.” This improvement of the building shell is not only noticeable in the heating season due to reduced energy consumption. The temperatures are also lower in the summer, making the working environment in the renovated halls more pleasant. Heat loss and draughts are counteracted through simultaneous operation of interlocking door groups and the existing airlock systems.

Three men with a green concept: Stefan Dambacher, Jürgen Abele and Berthold Ströbele

Green electricity for every new machine, an energy concept for every new building

Since January 2022, we have been drawing all the electricity for our machines and systems, but also for our lighting, office equipment, etc. from European wind power. This green electricity is certified with the “EKOenergy 100% Wind” label and is therefore CO₂-free. “The electricity from the grid is supplemented by 2.7 megawatts from photovoltaic systems – installed on four buildings at the plant so far,” says Purchasing Manager Stefan Dambacher.

“As a matter of principle, we construct new buildings to at least the KfW 55 standard, including our southern repair branch in Ehingen/Berg,” explains Abele. In addition, one third of the 12,000 square metre roof area on the building there has been greened. Another third, which is reserved for photovoltaics, is already occupied by a 142 kilowatt peak system. And the last third consists of skylights to deliver natural light into the building to reduce artificial lighting.

How heat storage and compressed air releases work: Compressed air is created when air is compressed by a high-pressure compressor. This produces heat that is fed into the buffer storage tank to heat buildings and halls. 1 Summer (S) – exhaust air | 2 Ventilation flap | 3 Winter (W) – heating | 4 Winter – recirculating air | 5 Buffer tank | 6 Air compressor (including heat exchanger) | 7 Summer – air supply

The role of the building control system

“We can use it to control every building in our plant,” explains Christian Wölfle from the Industrial Service Electrics department as he shows us an overview of flashing bars and numbers on his computer. “Via a central program, we can control, for example, lighting, heating, skylights, compressors, compressed-air or exhaust systems, and even the medical refrigerators used by our medical service. We can track the energy consumption of the buildings down to the individual machines with a connected load of more than 20 kilowatts. To work out how much energy we can save, we need to know our actual consumption.” More than 20 years ago, his supervisor Jürgen Abele began working on the building control system in the final assembly area. Among other things, it enables all compressed air consumption to be switched off centrally outside working hours to reduce losses. Once identified, potential for improvement is exploited using the latest technology and control systems, which were developed in-house. More than half of the lighting has already been converted to dimmable LED technology – and the trend is rising. “We can reduce our energy consumption by a further 30 per cent with the LED lighting by using a daylight-dependent control system, which we also developed in-house. Our team creates every control system, be it for lighting, heating, skylights and other applications, to suit the needs of the site and their colleagues,” Wölfle tells us proudly.

We design new buildings to at least the KfW 55 standard as a matter of principle.

Increasing mobility

Another aspect of the energy transition that we are tackling at our Liebherr plant is mobility management. One of the challenges is to accommodate the increasing number of employees within a limited parking area. “But commuter traffic also plays a role, especially at rush hour. In order to make the transport situation more environmentally friendly, socially acceptable and efficient, we are working on a mobility concept for our employees,” explains Fleet Manager Berthold Ströbele. A working group was also set up for this purpose, consisting of representatives from the HR department, works council, IT, production, plant planning and marketing.

Besides promoting electric mobility for cars and twowheelers, other potential measures include support for car-pooling, appropriate fleet and parking management, and improvements in the area of business travel. “We have already electrified nine vehicles in our fleet and ordered nine more. In addition, we are working on a concept for a bus shuttle service directly to the factory and are thinking about an employee app for carpooling,” reports Ströbele.

Christian Wölfle and Sophie Gantert check the heat flow meters on the canteenʼs heating manifold.

Embracing the future with an open approach to technology

“When we talk about the energy transition, we think of it holistically,” says Dr Ulrich Hamme, Managing Director Design and Development. “Logically, this also includes our products.” For almost two years now, we have been fuelling our cranes in Ehingen exclusively with pure HVO – a synthetic fuel that is largely carbon neutral and consists mainly of vegetable oil waste – for acceptance, test runs and for delivery. With regard to our products, HVO has the further advantage that there is no need to develop new machines or replace or upgrade the existing ones. You can continue working with HVO immediately.

“At Liebherr, our approach is to remain open to all types of technology. For our drive technologies, this means that they are adapted to the machine and the general conditions at the place of use,” says Dr Hamme. Therefore, besides HVO, there are still diesel vehicles as well as battery drives and e-fuels on the market. Being open to technology also means accepting that electrification does not always make sense and is not always possible. For example, construction sites in remote, inaccessible locations do not always have a reliable charging infrastructure. “When erecting wind turbines, the supporting infrastructure and power supply are first created using mobile and crawler cranes. Nevertheless, these energy-intensive machines must work reliably. In addition, in terms of the power source you need a different basic vehicle for electricity than for HVO, which means converting the vehicles for every job is not technically possible.”

A green future – in Ehingen and the rest of the world

“As you can see, we are doing a lot in terms of environmental protection here at our plant in Ehingen. And our products, in turn, are used all over the world to preserve our environment for future generations,” sums up Dr Hamme. For example, Liebherr cranes are used to erect wind turbines and power lines, and to build and expand photovoltaic plants and power storage facilities all over the world.

This article was published in the UpLoad magazine 02 | 2023.