What are job shops?

Small and medium-sized enterprises (SMEs) for contract gear manufacturing.

≤ 250 employees

≤ 50 Mio. euros turnover per year

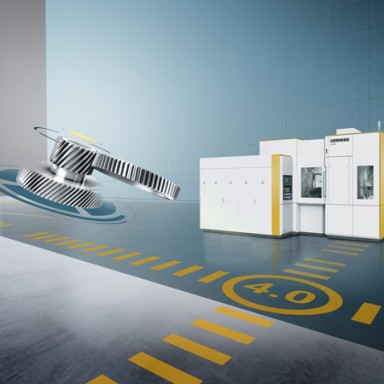

Job shops and manufacturers of small series and single parts must be able to react flexibly to market conditions and produce a wide variety of gear components. The workpieces range from very small or complex components, such as those used in robotics or aerospace, to standard gears used in industrial gearboxes, for example. Production may go all the way from small batch sizes to series production.

Special requirements in contract gear manufacturing

In order to meet market requirements in the medium and long term and to remain internationally competitive, the machines must be as universal, durable and upgradeable as possible. Particularly for medium-sized, often owner-managed companies that produce a wide variety of gears for different industries, this means that purchasing is not just a question of price, but also about investing in the future. In addition to the versatility of the machines, this also requires a partner that can be trusted to guarantee quality, and provide advice and support in the long term.

Machine overview

Partner for small and medium-sized companies

For a long time, Liebherr-Verzahntechnik GmbH was traditionally regarded as a partner of automobile and commercial vehicle manufacturers and their suppliers with large-scale production. However, the company has since long outgrown this image. “What many people don’t know is that Liebherr machines cover the entire gearing portfolio for job shops,” explains Dr. Oliver Winkel, head of technology application at Liebherr-Verzahntechnik GmbH. “Even our standard machines offer the full range of external and internal, straight and helical gears for workpieces such as ring gears, shafts and worm gears, with and without automation.”

Machines, consulting, support

Machines such as the LC 280 а universal gear cutting machine, the LS 400 EM gear shaping machine with electronic helical guide or the powerful LGG 700 M generating and profile grinding machine are particularly well suited for job shops. The WGT gear measuring machine ensures absolute precision and versatility in component measurement far beyond conventional gear checking (see machine overview). In addition, Liebherr offers consultation, support and service. “We contribute our expertise and experience and advise our customers when deciding on a specific machine or technology, because we view ourselves as partners,” Winkel emphasizes.