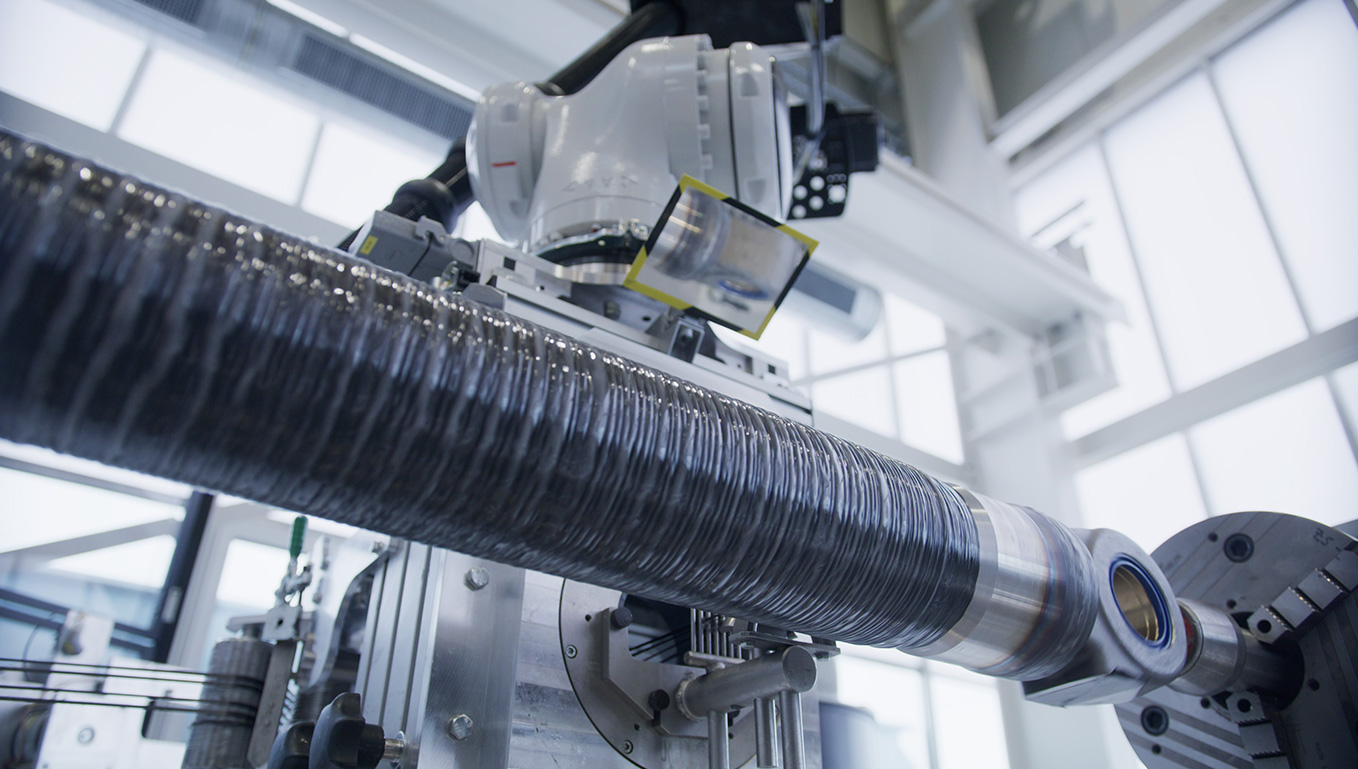

CFRP hybrid cylinder for heavy-duty applications: lightweight, smart and sustainable

In a world where heavy-duty machines must perform at peak efficiency while conserving resources and the environment, Liebherr's modular hydraulic cylinders drive sustainable, high-performance applications. Our future-ready cylinders offer the opportunity to open upnew fields of applications and meet increasingly stringent regulations and growing requirements.The sensor technology approachalso contributes to the future of autonomous construction machinery.

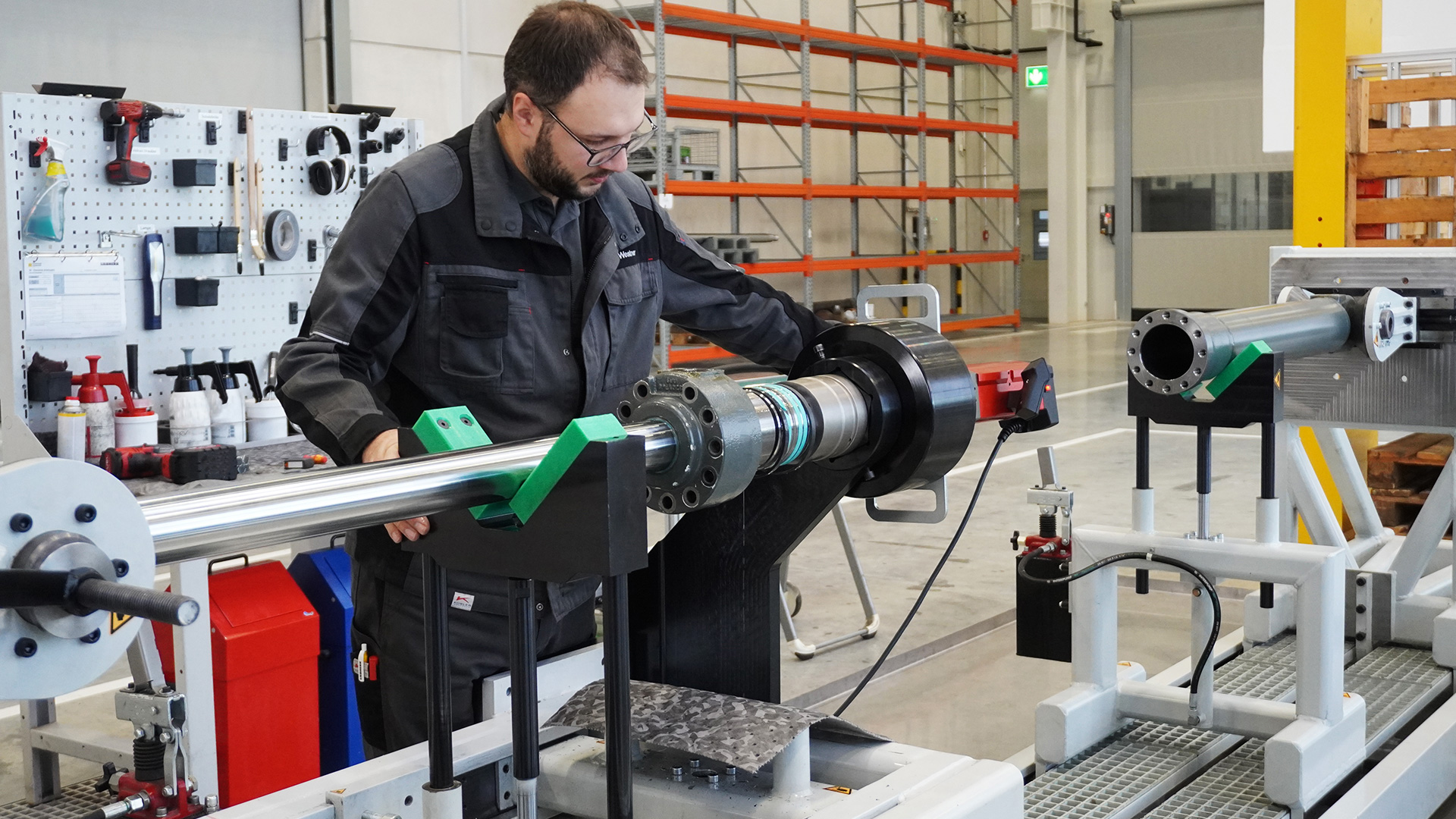

With a team of experts and state-of-the-art production facilities, the Liebherr-Components product segment develops hydraulic cylinders at its site in Oberopfingen, Germany.

What makes our hydraulic cylinders unique?

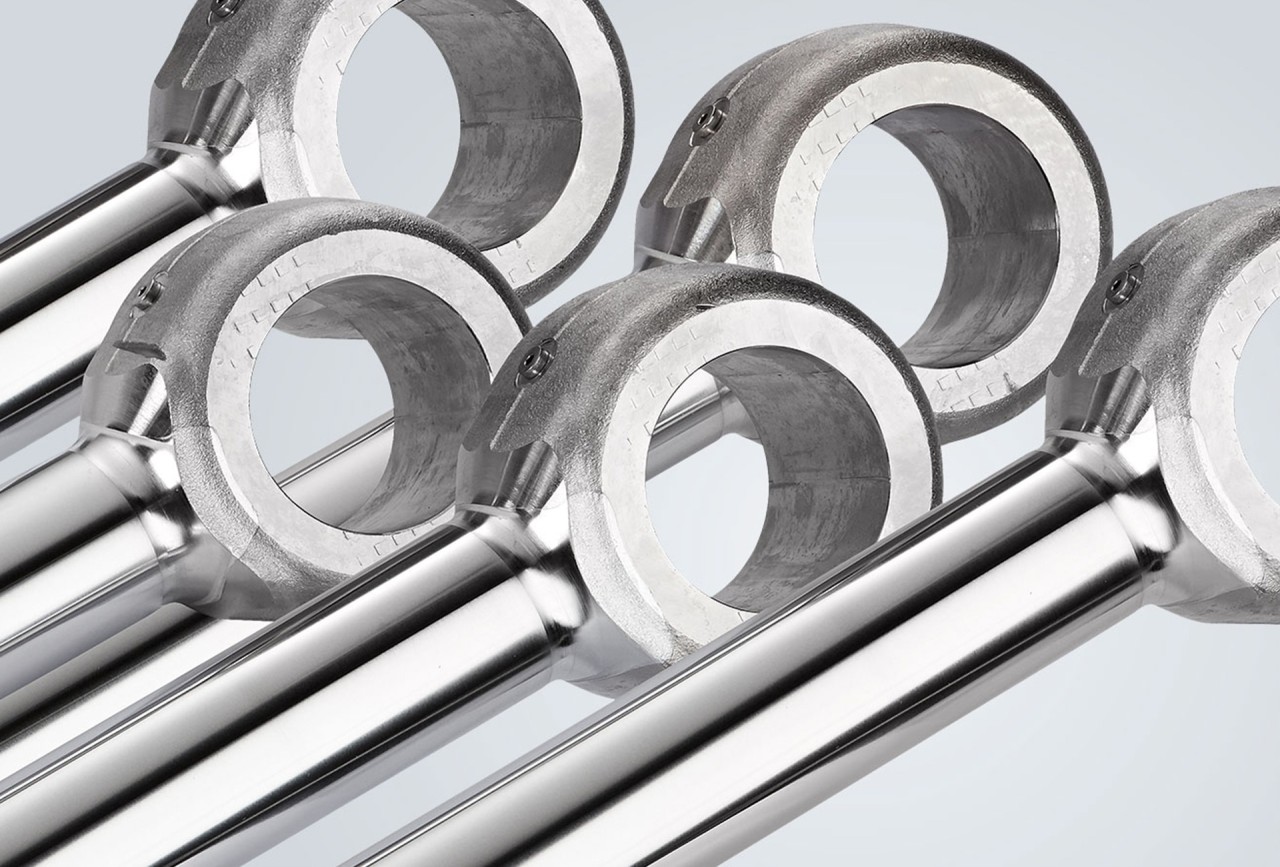

Lightweight

Smart

Sustainable

Longlasting & robust

CFRP hybrid cylinder for heavy-duty applications:

lightweight, smart and sustainable

In a world where heavy-duty machines must perform at peak efficiency while conserving resources and the environment, Liebherr's modular hydraulic cylinders drive sustainable, high-performance applications. Our future-ready cylinders offer the opportunity to open upnew fields of applications and meet increasingly stringent regulations and growing requirements.The sensor technology approachalso contributes to the future of autonomous construction machinery.

With a team of experts and state-of-the-art production facilities, the Liebherr-Components product segment develops hydraulic cylinders at its site in Oberopfingen, Germany.

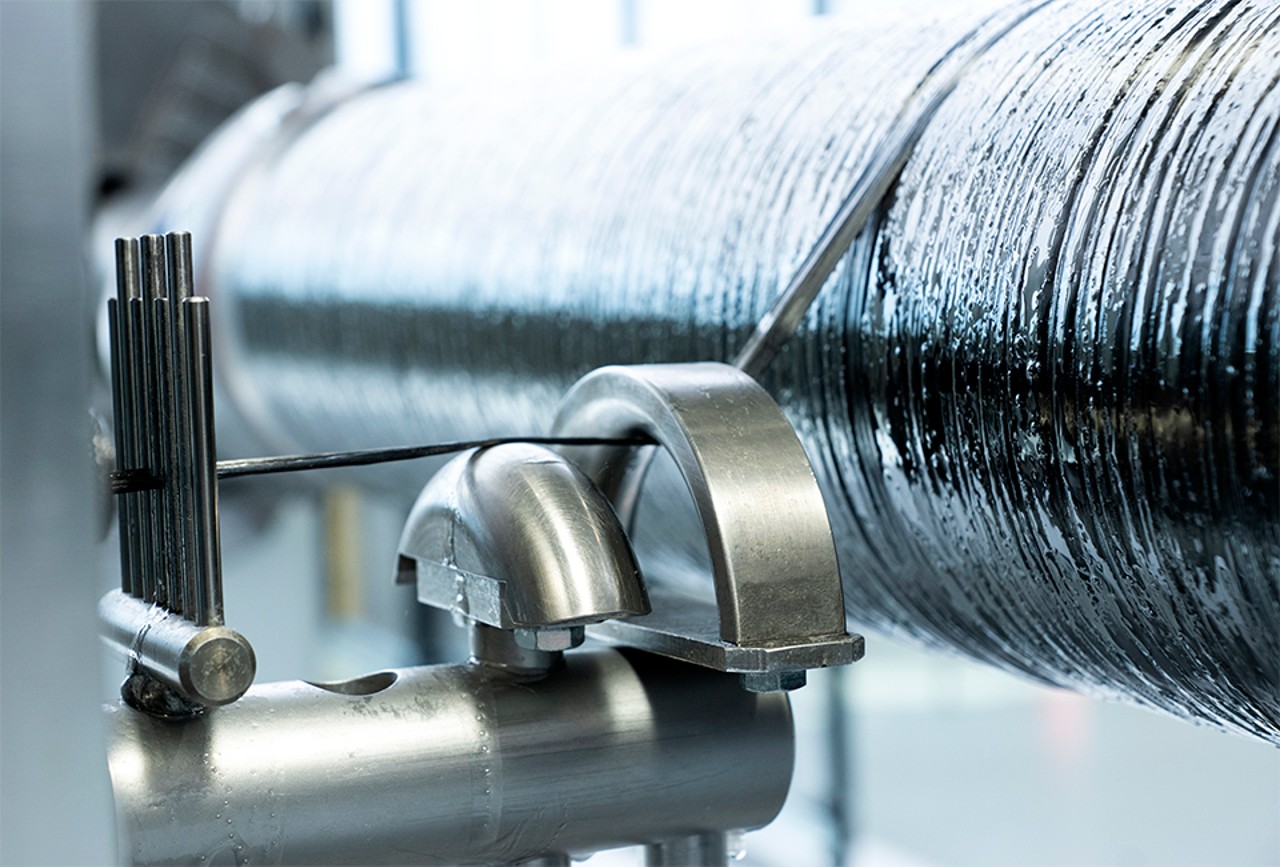

The future of smart hydraulic cylinders

Discover how sensor-based condition monitoring can revolutionise hydraulic cylinders. Integrated sensor technology monitors the condition of hydraulic cylinders in real time, enabling predictive maintenance and paving the way for automation and autonomous construction machinery.