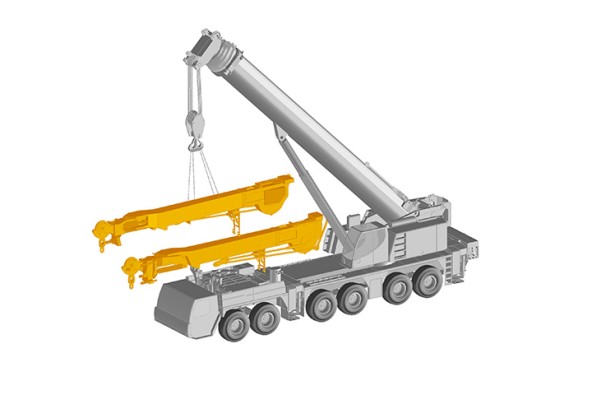

Folding jib

Quickly ready for use and particularly low cost

The folding jib significantly increases the working range of mobile cranes. On many crane models, the double folding jib can be carried on the crane with a 12-tonne axle load. Eliminating additional transport and extremely short set-up times make these mobile cranes particularly economical to run.

Functional additional equipment for the folding jib

Additional bespoke systems and components are available for every crane model to improve its flexibility even further.

- Folding jib extension

- Telescopic boom extension

- Various working angles for the jib

- Hydraulic adjustment under full load, lifting capacity interpolation

- Special folding jibs

- Different lengths

- Integral erection jib

- Hydraulically adjustable

- Rooster sheave

5.5 m erection jib,

hydraulically adjustable

Hydraulically adjustable folding jib

(0° to 40°)

Runner can be folded to the side

Erection jib, consisting of the folding jib

adapter and an additional roller set

or a hook traverse

Hydraulic assistance to mount

the folding jib with BTT

Hose drum for hydraulic adjustment

of the folding jib

Fixed jib

Increased hoist height and radius

The telescopic boom of our large mobile cranes can be extended using a fixed lattice jib. That enables to deliver great hoist heights and load capacities. The fixed jib is particularly helpful when working with projecting edges, such as on high buildings. It can be fitted at various working angles.

Luffing jib

Enormous working range with

lattice luffing jib

Our large cranes can cover a massive working range with a lattice luffing jib. That is ensured by infinite lifting capacity interpolation when luffing the boom combination. The luffing jib is used in particular for hoisting work which requires a large radius.

Automated raising of the luffing jib

A user-friendly automatic system allows the lattice luffing jib to be raised easily. The straightforward handling takes the strain off the crane operator and enhances safety. The crane operator only has to luff the telescopic boom. The adjustment winch is operated by the crane controller.

High load capacities with Y guying

Increased load capacity through greater lateral stability

Some of our mobile cranes with a lifting capacity of 350 tonnes or more can be fitted with telescopic boom Y guying. This delivers enormous increases in lifting capacity to be achieved, particularly on long boom systems since it significantly improves lateral stability. During the guying process, on some mobile cranes the ropes are set to exactly the same length on both sides by clamping cylinders so that the boom is held in the best possible straight position in static load terms.

Efficient assembly

Liebherr's telescopic boom guying systems are designed to be erected quickly and easily on site.

On some crane models the Y guying system can be mounted in self-assembly.

Manoeuvring on site

The design of the telescopic boom guying systems and the technical layout of the Liebherr mobile cranes allow that the cranes can be manoeuvred on site when erected.

More information

Your local contact

By clicking on “ACCEPT”, you consent to the data transmission to Google for this map pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each Google map individually in the future and want to be able to load them without this blocker, you can also select “Always accept Google Maps” and thus also consent to the respectively associated data transmissions to Google for all other Google maps that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Data protection settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and thr Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).