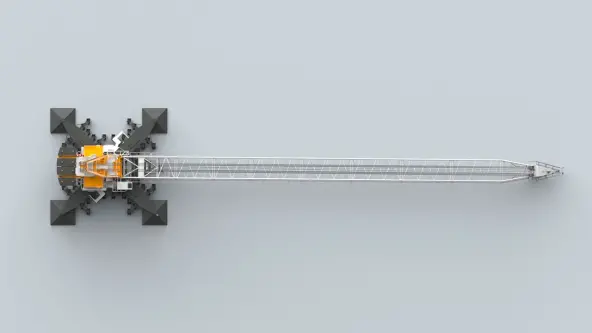

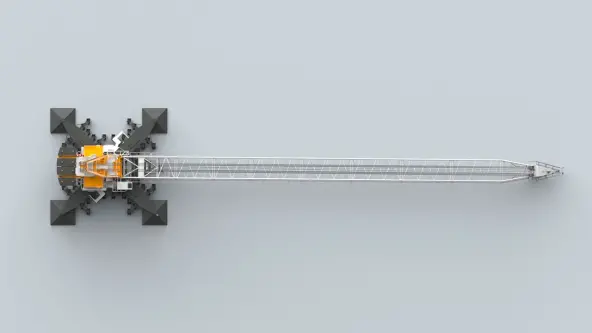

Flexibility with rapid mobilisation and superior lifting power

The Liebherr TCC 14000 is characterised by its unique flexibility. A short mobilisation time makes it a real game changer. By installing the crane on a mobile undercarriage, the crane can be used for a wide range of applications. Depending on the application, lifting capacities of up to 600 tonnes are possible. Lifting heights of up to 100 m can be realised.

- Design

- Cabin

- Maintenance

- Service

With its unusual design, the crane combines the high lifting capacity of a Board offshore crane (BOS) with the unique flexibility of a mobile harbour crane. The BOS crane design has been developed in accordance with offshore standards and meets the highest requirements. It has proven itself over decades with its functional and application-optimised construction and is mounted on an X-shape undercarriage. This allows it to be manoeuvred flexibly in all directions and positioned precisely.

With its unusual design, the crane combines the high lifting capacity of a Board offshore crane (BOS) with the unique flexibility of a mobile harbour crane. The BOS crane design has been developed in accordance with offshore standards and meets the highest requirements. It has proven itself over decades with its functional and application-optimised construction and is mounted on an X-shape undercarriage. This allows it to be manoeuvred flexibly in all directions and positioned precisely.

The assembly of the TCC 14000

The TCC 14000 was manufactured at our site in Rostock on the Baltic coast. The video shows the assembly of the crane on the test stand in fast motion. Watch as our skilled team brings this impressive piece of machinery to life.

Boom

Find out more

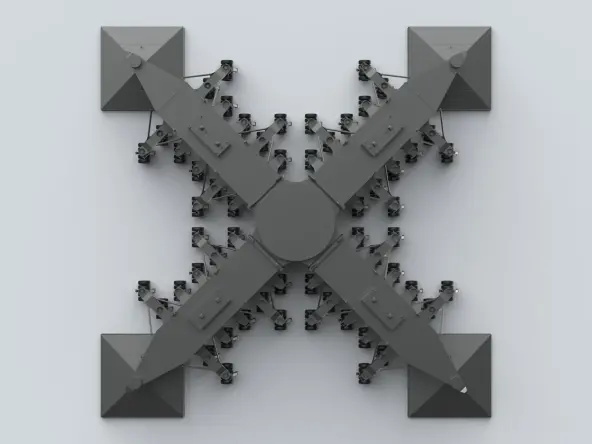

Undercarriage

Find out more

Mobilisation

Find out more

Machinery housing

Find out more

Drive system

Find out more

Load bearing

Find out more

Get in touch

Areas of application

The TCC 14000 can be used for a wide range of applications. The main applications include the pre-assembly of wind turbines and the handling of large and heavy loads. This can be used in the maritime environment of a harbour as well as for support in other branches of industry.

Wind energy sector

The Liebherr TCC 14000 is an effective solution for the wind industry for handling and preparatory assembly work on wind power components for onshore and offshore wind farms. The TCC 14000 offers high availability even in strong winds, which often prevail in harbour environments. Crane operation can be guaranteed at wind speeds of up to 25 m/s. It impresses with its excellent manoeuvrability in tight harbour facilities and confined spaces.

Industrial sector

The TCC 14000 can be used for a wide range of applications in large industrial plants. On the one hand, for lifting and loading heavy and oversized parts and components as well as for assembly support in large industrial structures. On the other hand, applications in scrap handling of large structures, such as the scrapping of maritime structures or other heavy industrial plants, are a possible field of application.

Benefits of the undercarriage – 360° mobility

All wheel sets are individually steerable. The 360° mobility ensures highest maneuverability. This allows curves at any possible radii and even slewing on the spot and facilitates effective positioning of the crane. This is a decisive advantage at confined spaces. All wheel sets have load balancing, whereby the ground pressure will be levelled out for each wheel. Furthermore, the accessibility for maintenance purposes is ensured.

Benefits of the undercarriage – optimal stability

The crane has an x-shaped supporting base. This is optimised for the crane's intended use and enables the reduction of the torsion strain on the steel structure and ensures optimal vertical stability during operation. The size of the support base can be customised to suit the customer's ground conditions. This allows a wide range of applications to be realised.