Analyse your crane performance

Numbers are everywhere in our lives, and statistics is about turning these numbers into useful information on which we can take action. Getting the right information at the right time is the key to act on a process level. Big data analytics examines large amounts of data to uncover hidden trends, anomalies and other insights.

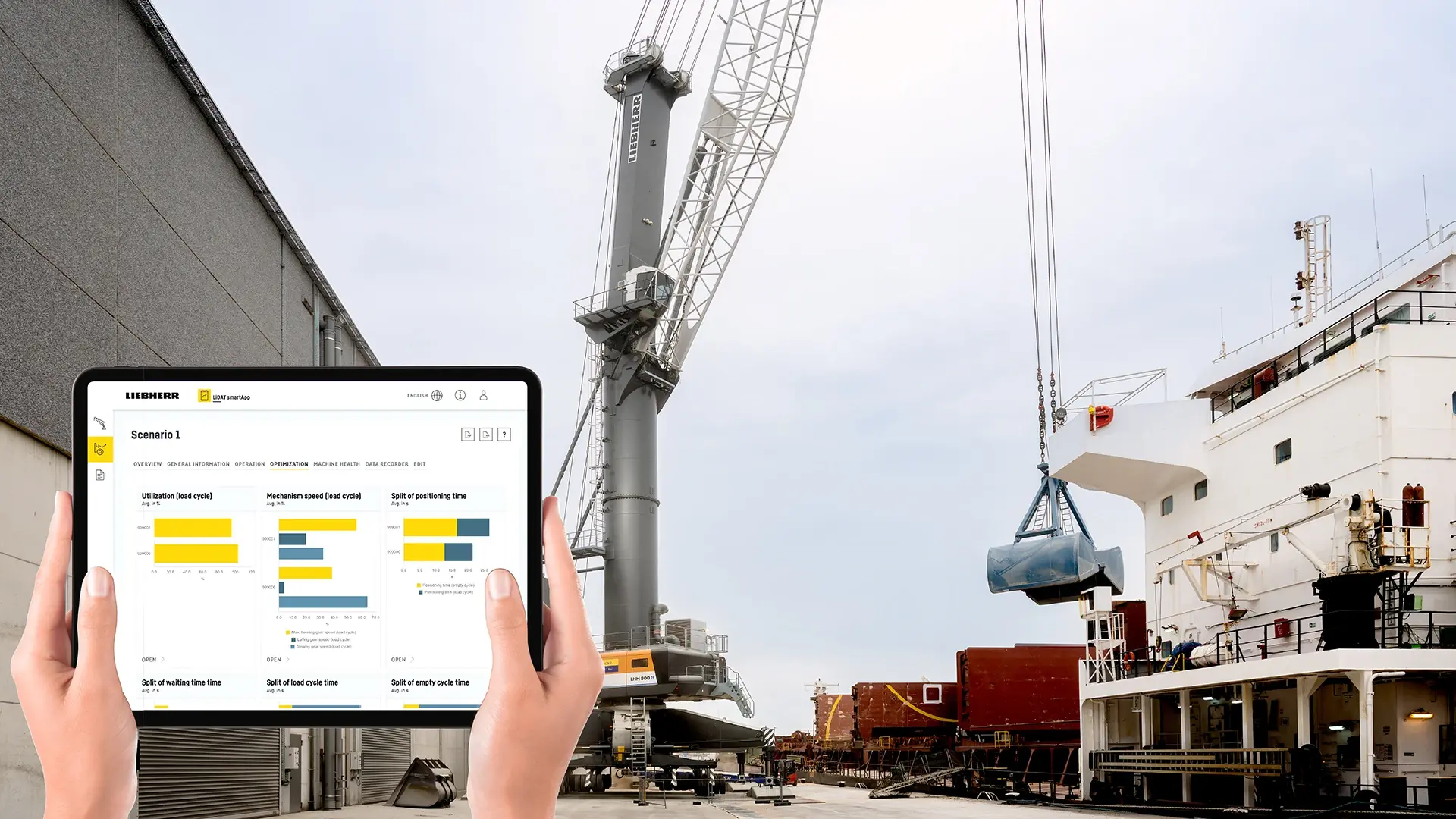

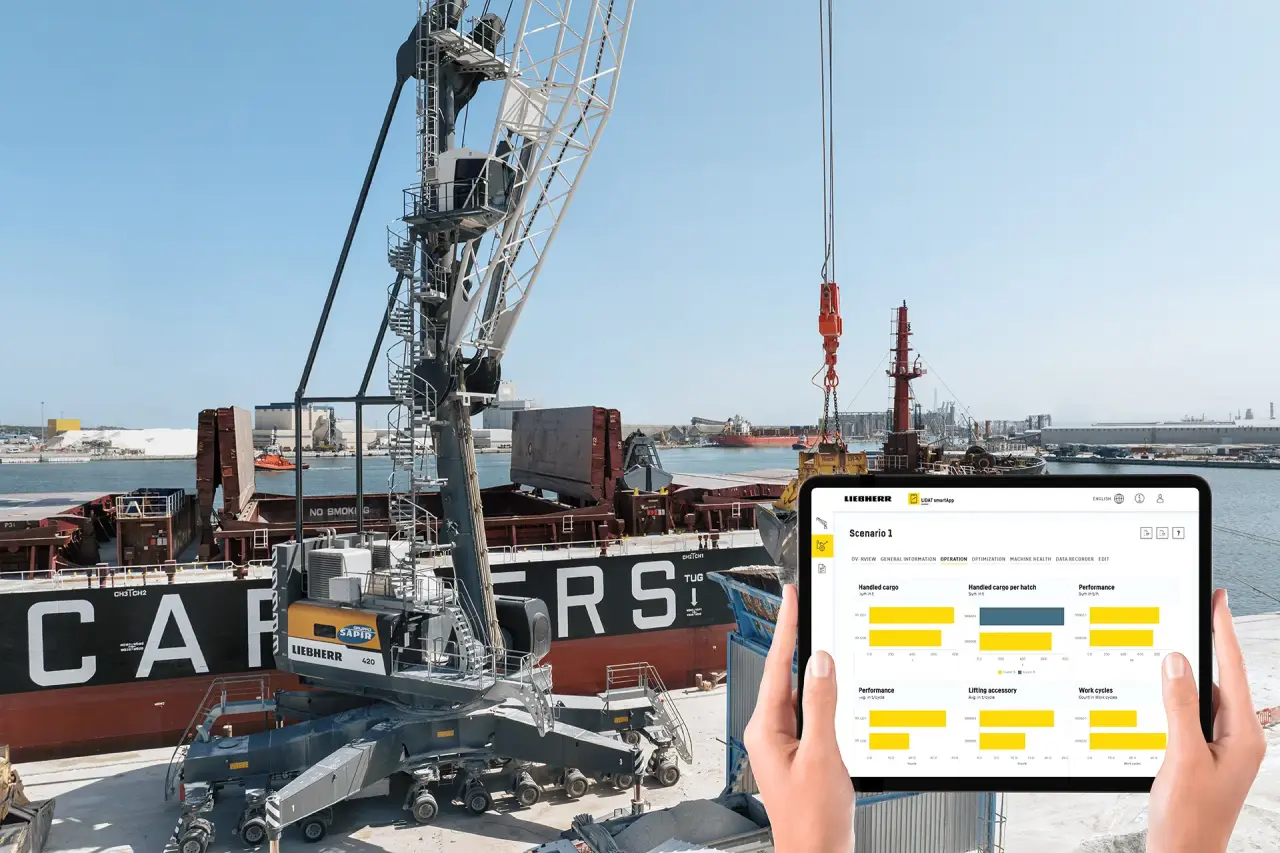

With LiDAT smartApp, it’s possible to analyse your crane (operating and performance) data and get answers from it almost immediately. That leads to immediate decisions. The ability to work faster gives ports a competitive edge they didn’t have before. Big data analytics helps to detect bottle necks and to identify new opportunities.

Functionality

Basically LiDAT combines crane technology and data transfer logic. Big data analytics is where advanced analytic techniques operate on big data.

The online work cycle detection on the crane records specific values during the crane operation.

Process data are transmitted in real time to the LiDAT server centre, where the analysis is taking place.

Detailed process data incl. data from load recorder are displayed as key performance indicators (KPIs) on any device.

The result of the analysis can be printed as PDF-report. Results of the Position Optimizer can be transmitted back to the operator via LiDAT and shown on the operators display.

Get in touch

More information or direct to the shop

Talk to our specialists to learn more about the LiDAT smartApp and its useful features.

You want to purchase a licence for your maritime crane?

Register your company on MyLiebherr!

Features and benefits

Detailed view

- In-depth analysis for performance condition of machines

- Comparision of multiple machines

Optimisation

- Giving the user direct guidelines to improve processes

- SmartApp proposes optimisation actions (Position Optimiser)

- Optimisation information can be sent to the crane/driver for immediate action

Reports

- Download turnover process reports and machine reports

- KPIs allow for a quick overview about a single machine or a set of machines to decide on further actions

- Monitor your cargo handling process in real time (process visualisation)

Telematic System for Big Data Analytics

ISO certification

The Certification Body of TÜV SÜD Management Service GmbH has certified our Liebherr plants in Bischofshofen and Nenzing for having established and applied an Information Security Management System according to “Statement of Applicability” for development, operation and support of applications responsible for providing process, service and operating data of Liebherr machines.

Proof has been furnished that the requirements according to ISO/IEC 27001:2013 are fulfilled.