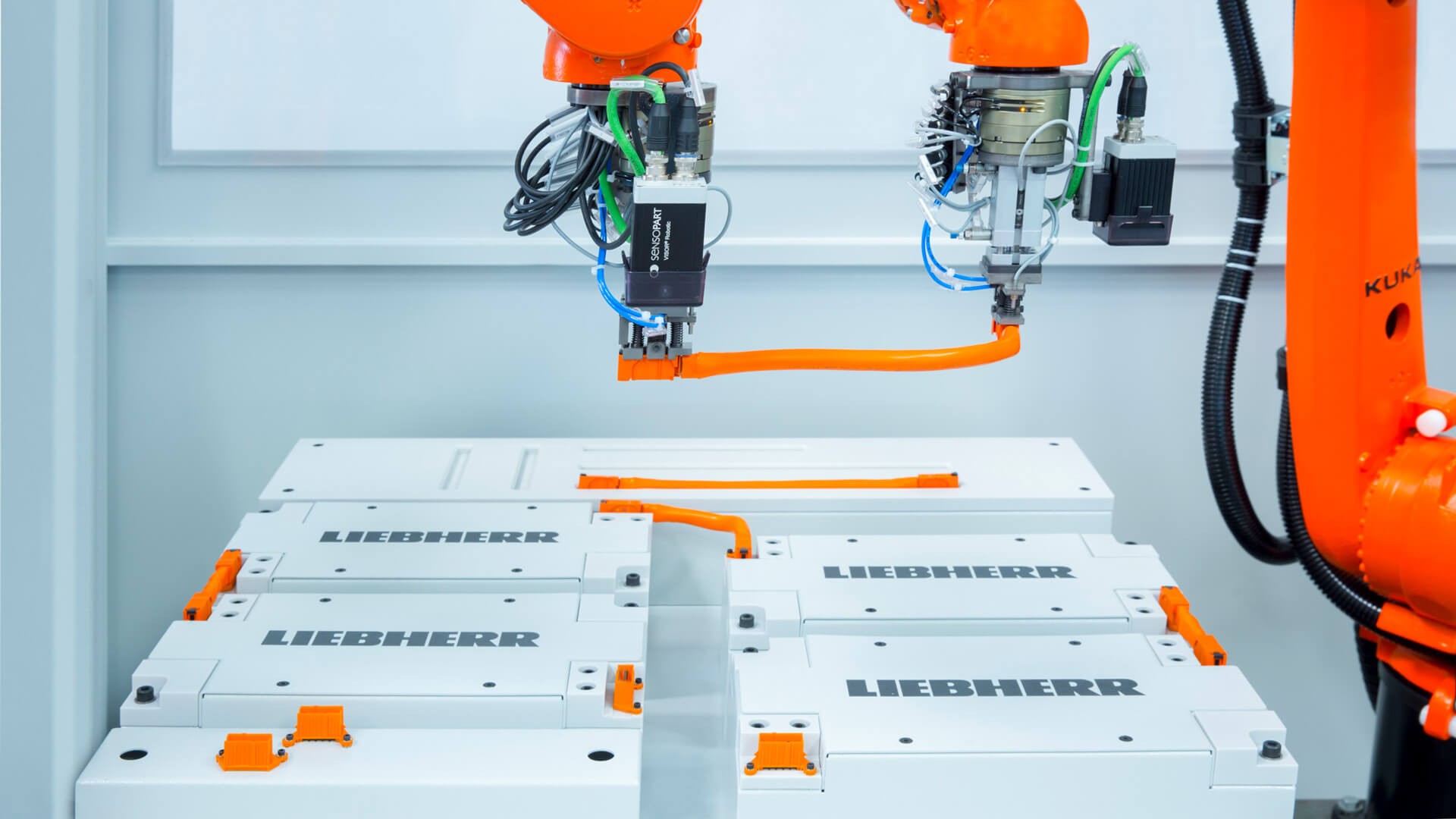

Liebherr automates the assembly of pluggable module connectors

Plug connections for electrical contacting of modules in the battery pack offer several advantages. However, until now it was only possible to assemble them manually – an obstacle for large batch sizes. Liebherr, together with KOSTAL Kontakt Systeme GmbH, has developed an innovative solution for the automation of the plugging process.

The modules installed in the high-voltage battery must be electrically contacted with each other. Currently, screw connections with busbars made of copper material are predominantly used for this. It is also possible to use plug connections with flexible cables or busbars.

Advantages of plug connections

Compared with screwed and rigid busbars, plug connections with flexible cables offer a number of advantages:

- Easy assembly: Only the plug and counterpart have to be connected. This also facilitates the disassembly of the modules in the battery pack during later servicing, for a second life or for battery recycling. The flexible cables can also compensate positioning tolerances in the battery modules of several millimeters.

- Safety: Normed, touch-protected contact parts mean that no danger is presented by exposed electrical high-volt contacts.

- Robustness in practice: If there are strong vibrations in the vehicle, screwed busbars can detach themselves. The flexible cables with the plug connections are able to compensate for these vibrations.

Video

E-Mobility solutions by Liebherr

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Data protection settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Automated plugging of high voltage battery module connectors

Challenge: the automation of soft parts

For these reasons, there is growing interest from manufacturers in pluggable connections. However, since the automated assembly of soft components presents an engineering challenge, this has till now still been carried out manually. This can cause a bottleneck in production if batch sizes increase. The problem is that the parts have low resistance against shape changes. They already become very highly deformed as a result of even small stresses, such as their own weight. These changes in shape are often a rejection criterion for the automation of handling or assembly processes.

Innovative automation solution by Liebherr

Liebherr has developed a unique solution for this to enable the automated, process reliable, plugging of module connections. Two cooperating robots each grip one end of the cable and carry out the plugging process synchronously with temporally and geometrically coordinated movements. Using a 2D camera, the robot detects the real position of the slots, thus enabling positioning tolerances to be compensated. The actual, mechanical plugging process is performed using a pneumatic cylinder. A spring assembly limits the force transfer to the module, plug and plug lock to secure the position (CPA). Finally, process reliable monitoring is performed by a stop position sensor. Liebherr can also solve the laying of the cables in the desired position and geometry using suitable cable bend grips.

KOSTAL Kontakt Systeme GmbH

Sector:

Development, production and distribution of plug systems for the automotive industry

Company size:

1,400 employees

Founded:

1993

Company headquarters:

Lüdenscheid, Germany

Sites:

9 sites on three continents: Dresden (Germany), Goldthorpe (Rotherham, Great Britain), Gyancourt (France), Jince (Czech Republic), Turin (Italy), Rochester Hills (Michigan, USA), Shanghai (China), Seoul (Korea)

Turnover:

approx. €3 billion

Website:

www.kostal-kontakt-systeme.com/en-us/