System solutions from a single source – worldwide

A year ago, Wenzel GearTec GmbH, a successful manufacturer of gear inspection machines, was integrated into Liebherr-Verzahntechnik GmbH. How are the customers, technology and employees benefiting from this today? We spoke to Peter Biemer, Liebherr’s divisional Head of Sales Gear Cutting Machines, and Heinrich Brüderle, Head of Measuring Technology, formerly of Wenzel GearTec GmbH.

Measuring technology has been part of the Liebherr portfolio for a year now. How would you assess the integration from today’s perspective?

Peter Biemer: Liebherr has successfully expanded its portfolio as a full-service provider. Integrating measuring technology into the company was an important strategic step and the logical development of the partnership which has existed since 2015 with Wenzel GearTec GmbH. We can now offer coordinated system solutions for gear cutting and inspection machines from a single source.

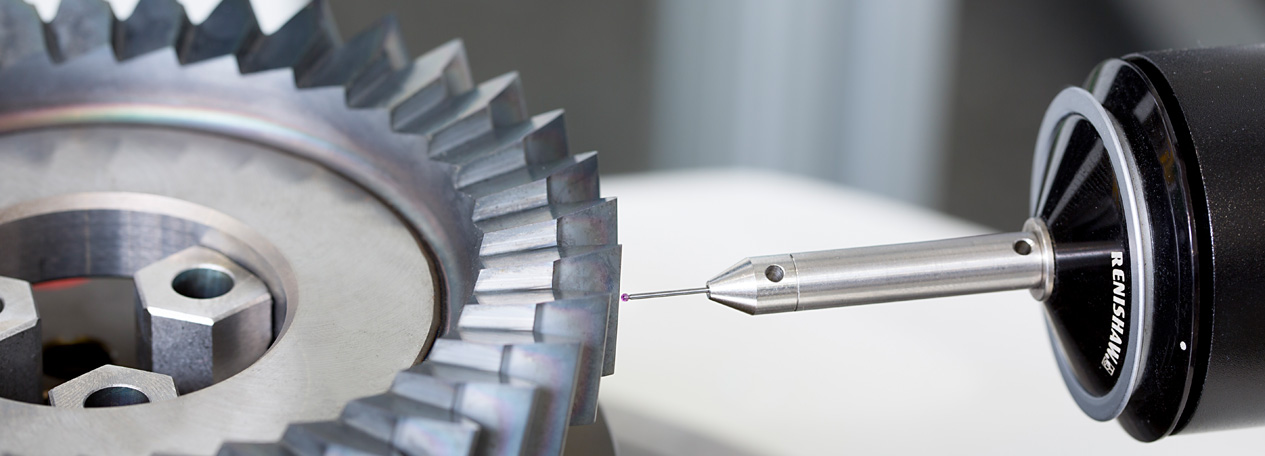

Heinrich Brüderle: Our measuring instruments are known for their optimum accuracy when inspecting gears. The existing partnership with Liebherr made it clear to us that the integration was the right step in order to advance our technology together and continue to offer it to our customers at the highest level. The synergy effects can already be seen in the development of LHOpenConnect and other system solutions.

At EMO 2019, you presented a solution for transferring data between production machines and inspection machines. Your solution is called LHOpenConnect. How does it differ from the closed loop approach?

Peter Biemer: At EMO 2019, Liebherr presented the WGT 280 inspection machine, which has a manufacturer-neutral GDE interface for transferring data to the production machine. We have expanded this concept into a system which, unlike a “closed” loop, is based on open data structures and connectivity. The LHOpenConnect software enables the user to exchange data with other processing and inspection machines, control centers and data analysis systems, even more flexibly and across different processes (more information here).

So you’ve already achieved synergy effects on the technical side. What other advantages of integrating measuring technology do you see?

Heinrich Brüderle: Customers around the world benefit from our expanded product range, improved service network and greater international sales network. Because Liebherr has so many sites, we are never too far away from customers and can offer local service and support.

Drawing a positive conclusion: Heinrich Brüderle (left) and Peter Biemer

What has changed for the former employees of Wenzel GearTec?

Heinrich Brüderle: All 25 employees at the Karlsruhe and Shanghai sites were taken on. They appreciate the benefits of an international family business that is not only run for short-term profit. Our workforce sees the whole thing very positively. And that’s also very important to us, because one of the most important factors in our success is the people who put in the work every day.

What do you think are the future challenges for Liebherr measuring technology?

Peter Biemer:The future trend will be towards automation and data exchange. Because Liebherr is working intensively on this and it’s one of our core areas of expertise, I’m optimistic that we’ll stay at the forefront in this area.

Heinrich Brüderle: We will be dealing with the area where automated, production-related and unmanned measuring systems interact with the expertise of the people who operate them. With Liebherr, we have the right technology partner to be able to offer our customers stability and certainty.