Gears are in continuous contact with each other under high load, with fast movement. Therefore, it is immensely important that they comply with predetermined quality standards, to keep noise generation as low as possible, for example. Their quality is also a significant factor in the prevention of premature wear and, as a result, the prevention of gearbox failure. Machines for gear inspection, such as the successful WGT series from Wenzel GearTec, are predominantly used in gear manufacturing for gearboxes in the auto, truck, rail vehicle and aerospace industries as well as in mechanical engineering, where they ensure high precision.

Integration of measurement technology

Wenzel GearTec GmbH, a successful manufacturer of gear inspection machines, has been part of Liebherr-Verzahntechnik GmbH since May 2019. The Karlsruhe-based company has specialised in the measurement of gears, gear cutting tools and other rotationally symmetrical workpieces since 2004 and has an innovative product range that perfectly complements Liebherr's own.

The star: the WGT series

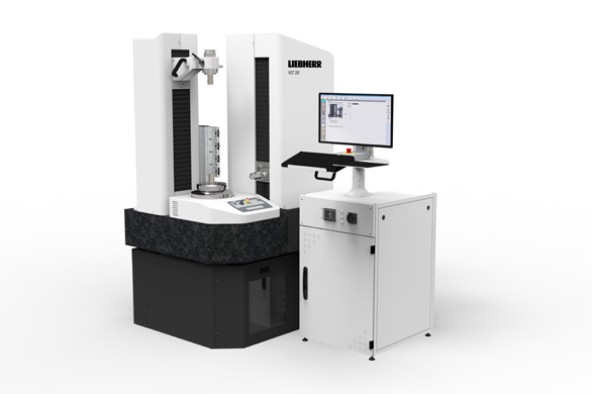

The 4-axis measuring instruments of the WGT series have high-precision mechanics and electronics, which are controlled by smart software. Machines for gear inspection must fulfil even stricter specifications than machines for gear manufacturing: they comply with the VDI guideline VDI/VDE 2613, group 1.

The WGT machine is not the solution – it is part of the solution. The application team examines the specific requirements and then configures a system that fulfils them. Gear inspection machine options include travel ranges on the Z-axis adapted to customer requests, longer tailstocks for mounting longer shafts and various rotary tables for the right load capacity. An automatic probe change system ensures uninterrupted measurement of the workpieces. Thanks to its wide range of accessories, a WGT machine can be perfectly adapted to meet customer requirements and individually configured. It is suitable for all types of gears, such as cylindrical gears, bevel gears, worms, worm wheels, shafts, gear cutting tools and other rotationally symmetric parts.

All machines are equipped with Renishaw probes. They offer the highest precision at low operating costs. The international Renishaw team supports customers and Liebherr and is responsible for the global supply of spare parts, probes and accessories as needed.

Liebherr is renowned around the world as a trusted employer and we are proud to be part of a global company

An option for the future

Nothing will change for existing customers and staff at Wenzel GearTec because of the acquisition. “Liebherr is renowned around the world as a trusted employer and we are proud to be part of a global company,” Heinrich Brüderle, divisional manager at Wenzel GearTec GmbH, states. Wenzel and Liebherr have been partners since 2015. The goal of this year’s acquisition was to be able to offer closed-loop system solutions from a single source.

Dr Christian Lang, General Manager of Sales and Marketing at Liebherr-Verzahntechnik GmbH, is positive about the acquisition: “We are delighted that we were able to finalise the negotiations in an efficient and constructive manner. Now we are able to include gear cutting measurement technology in our range of products and work together on technological development.” Former managing partner Frank Wenzel agrees: “We know our company is in safe and reliable hands.”