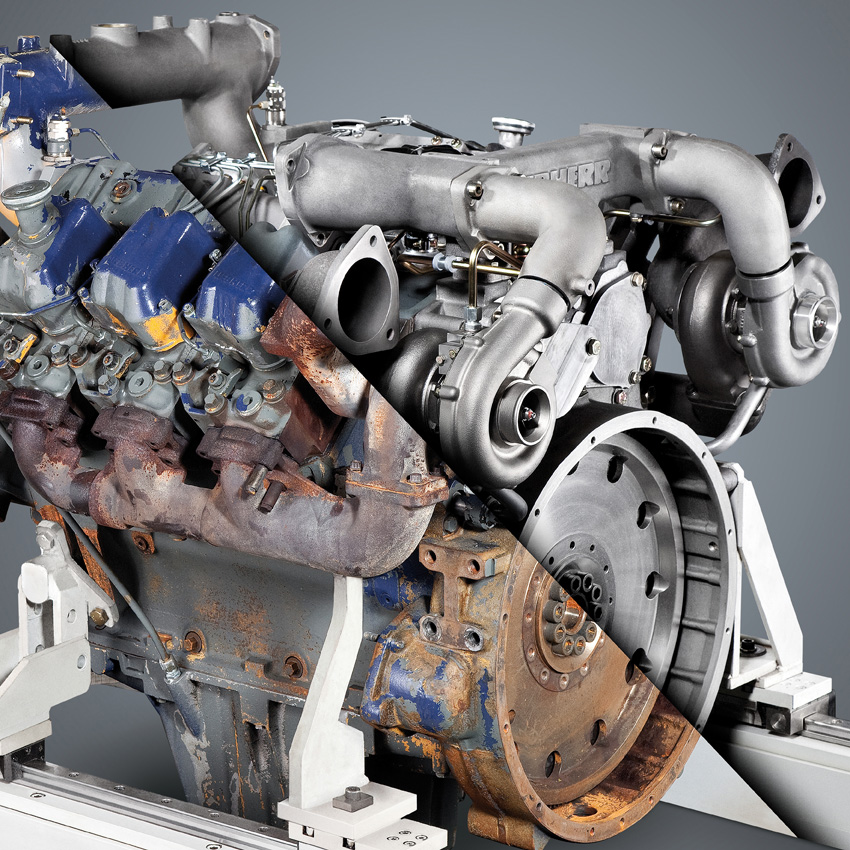

Savings potential through recycling of components in the Reman programme

- Remanufacturing gives a 60% reduced CO2 footprint for the components from a diesel engine with the same quality as for new parts.

- Factoring in the replacement of cores no longer used by new parts, the CO2 saving is still more or less half.

- The CO2 saving essentially results from retaining massive components made from materials such as steel and cast iron. An ability to reuse about three quarters of the cores (old parts) after corresponding cleaning and reconditioning means that these are no longer destined for scrap.

- This does away with the need to melt down old metal again – an energy-intensive process – while eliminating a certain element of the primary production for metals and costly manufacturing of new components.

- Depending on the supply chain, the transport expense for returning the cores (old parts) by road transport can be slightly higher than for new parts.

- As regards the CO2 footprint, this extra expense is of minor significance and is surpassed by the considerable savings in regard to materials and processing expenditure.