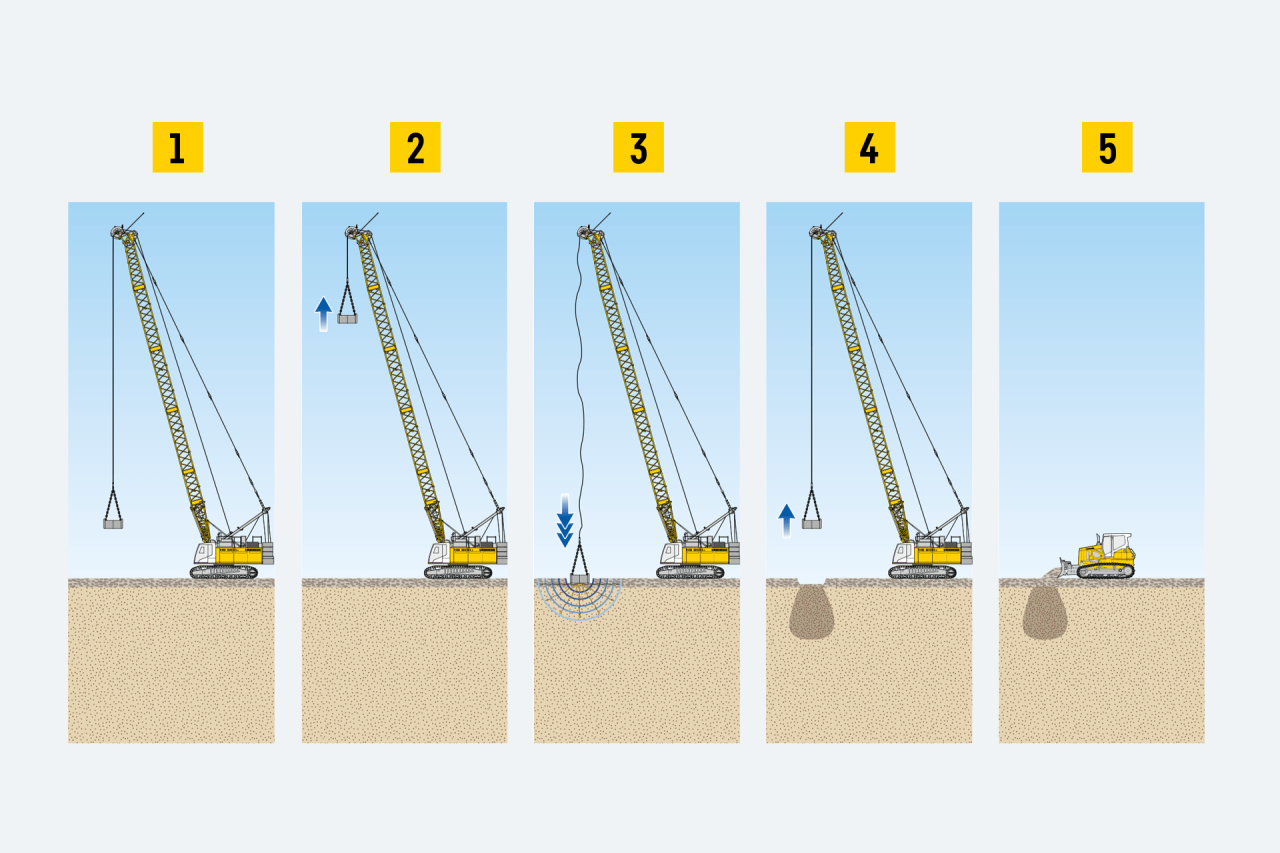

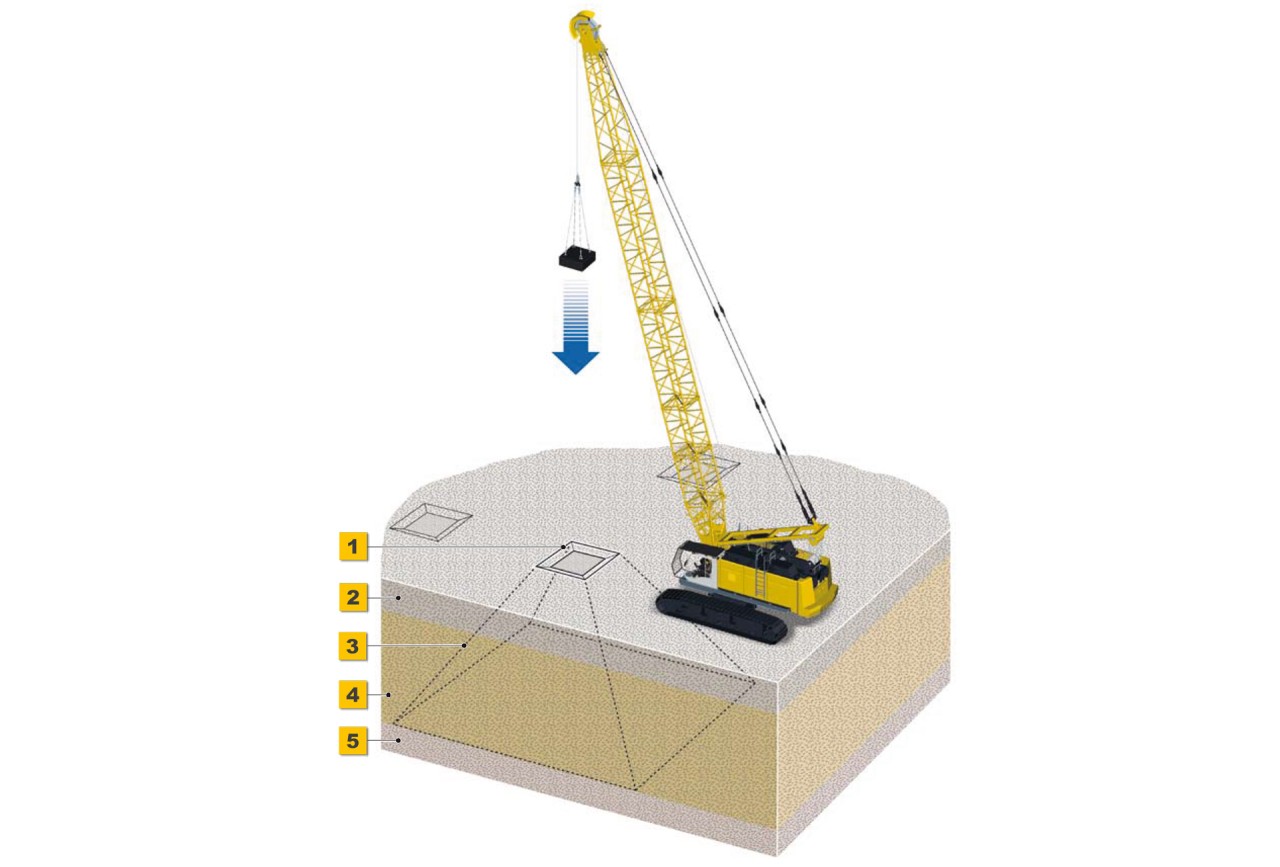

For impact compaction a heavy tamper weight is dropped from heights of up to 40 metres onto the ground to be compacted. This dynamic input of energy increases the density of the building ground. The craters created through impact compaction are refilled with suitable material and further compacted, if necessary. Duty cycle crawler cranes of the HS series carry out the compaction process efficiently and automatically with free-fall winches and crane control.

01/02

01/05

Video

Machines

Results 1–2 of 4

1

2

Video impact compaction

Impact compaction is particularly suitable for the compaction of sandy soils for land reclamation.