Double rotary drilling

A single-pass drilling method

Cased continuous flight auger drilling (CCFA)

Double rotary drilling combines continuous flight auger drilling with a continuous casing. Casing and auger (inside the casing) are simultaneously installed and extracted. Double rotary drilling is applied for the production of cast-in-place piles and for predrilling.

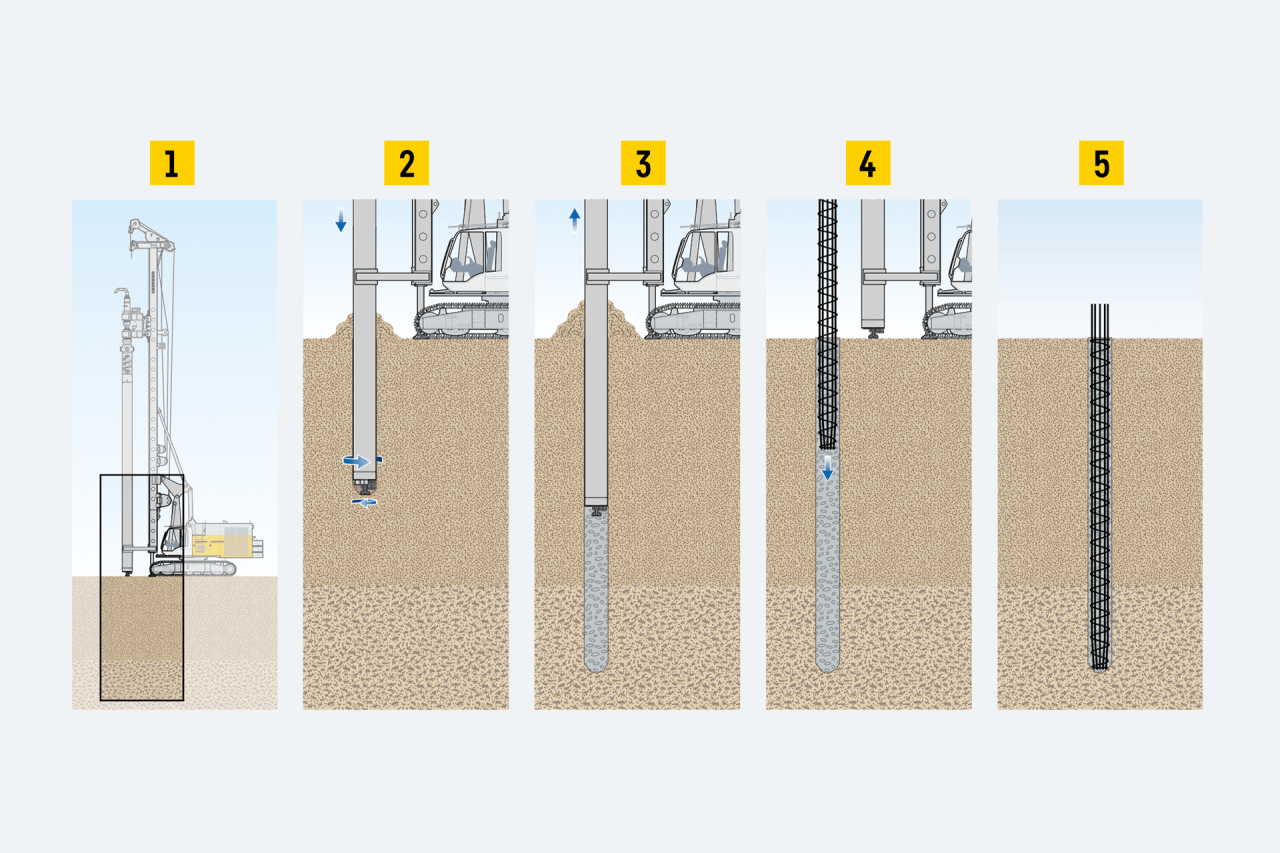

Procedure of producing a cast-in-place concrete pile with double rotary drilling:

1. Positioning at the drilling point

2. Auger drilling with simultaneous advance of the casing

3. Extraction of auger and casing while concrete is pumped in through hollow stern

4. Inserting the reinforcement

5. Finished pile

Video double rotary drilling

The video shows two jobsites with double rotary drilling for producing cast-in-place piles.

Combination of continuous flight auger and casing

This method combines continuous flight auger drilling with a casing. It is mainly applied for producing cast-in-place piles.

Double rotary drilling

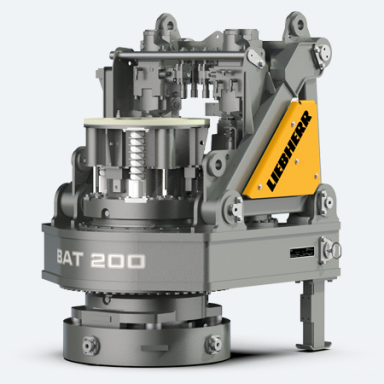

Two rotary drives are separately mounted on the sledge and independently drive the inner continuous flight auger and the casing.

Installing cast-in-place piles

During the drilling process the auger flights convey the drill cuttings to the surface inside the casing. Through an opening at the upper end of the auger the drill cuttings are ejected.

“Front-of-wall” drilling

The compact design of the double rotary head allows operation very close to existing building structures, i.e. in front of building walls.

Protection cover

A protection cover encloses the casing so creating an annular space inside. Thus, the ejected drill cuttings fall to the ground in a controlled manner.

Emptying the auger

After their extraction, casing and auger are swung to the side and emptied by rotating the auger in the reverse direction.

Extracting and concreting

After the final depth has been reached concrete is pumped through the auger’s hollow stem. During the extraction process the concrete exits at the lower end of casing and auger.

Reinforcement

After concreting a reinforcement cage can be inserted in the column of fresh concrete. For this purpose the auxiliary winch of the carrier machine is used.

Machines

Operating weight - 52.8 t

52.8 t

Max. torque - 200 kNm

200 kNm

Kelly drilling, max. drilling depth - 34.5 m

34.5 m

Kelly drilling, max. drilling diameter - 1,500 mm

1,500 mm

Operating weight - 69.3 - 79.9 t

69.3 - 79.9 t

Max. torque - 252 kNm

252 kNm

Kelly drilling, max. drilling depth - 53.2 m

53.2 m

Kelly drilling, max. drilling diameter - 3,300 mm

3,300 mm

Operating weight - 71.1 - 82.1 t

71.1 - 82.1 t

Max. torque - 252 kNm

252 kNm

Kelly drilling, max. drilling depth - 53.2 m

53.2 m

Kelly drilling, max. drilling diameter - 3,300 mm

3,300 mm

Operating weight - 73.6 - 84.6 t

73.6 - 84.6 t

Max. torque - 297 kNm

297 kNm

Kelly drilling, max. drilling depth - 70.8 m

70.8 m

Kelly drilling, max. drilling diameter - 3,400 mm

3,400 mm

Operating weight - 75.5 - 85.5 t

75.5 - 85.5 t

Max. torque - 297 kNm

297 kNm

Kelly drilling, max. drilling depth - 70.8 m

70.8 m

Kelly drilling, max. drilling diameter - 3,400 mm

3,400 mm

Operating weight - 99.0 - 111.1 t

99.0 - 111.1 t

Max. torque - 347 kNm

347 kNm

Kelly drilling, max. drilling depth - 77.5 m

77.5 m

Kelly drilling, max. drilling diameter - 4,100 mm

4,100 mm

LRB 18 with double rotary drive DBA 80

Pile wall must be installed for the foundation of residential and business premises in an extremely tight space.

The Positioning System LIPOS supports double rotrary drilling

320 piles for new build logistic centre.

800 piles for new apartment buildings

The LRB 355 requires, under optimum conditions, only 14 minutes to complete a cast-in-place pile.

Foundation work for a multi-storey office and appartment building

The powerfull piling and drilling rig LRB 355 installs 316 piles for a secant pile wall.

Tools for professionals

- Augers, auger starters, casings, cutting shoes

- Wear parts (chisels, teeth, pilot bits, blocks)

Get in touch

If you have any further questions, please contact our local sales or service team.