Lifinity: Solid lubrication

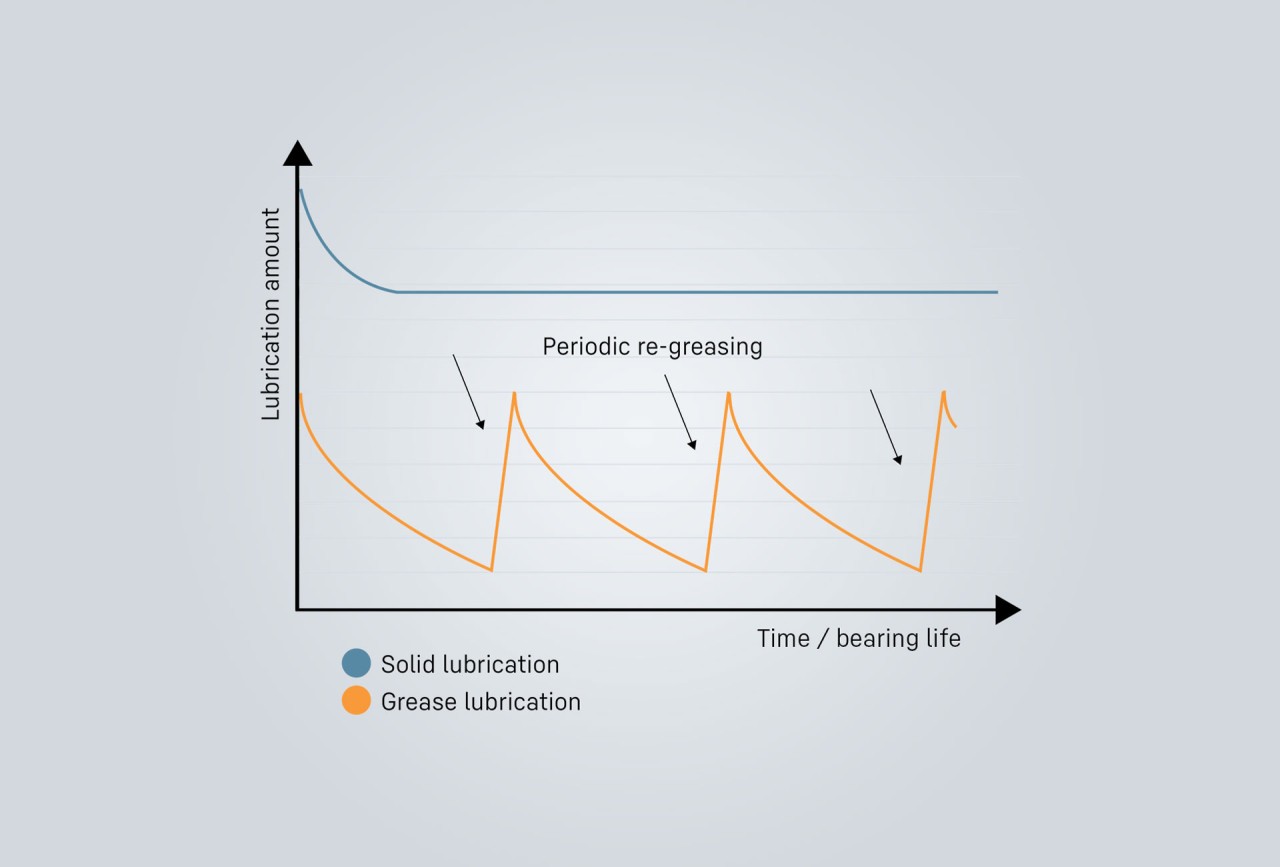

Discover the breakthrough solution that eliminates the hassle of regreasing slewing bearings and slew drives. With Lifinity, we have revolutionized the industry by providing a seamless and long-lasting lubrication solution that ensures optimal performance throughout the lifespan of your equipment.

Lasts forever, serves a lifetime

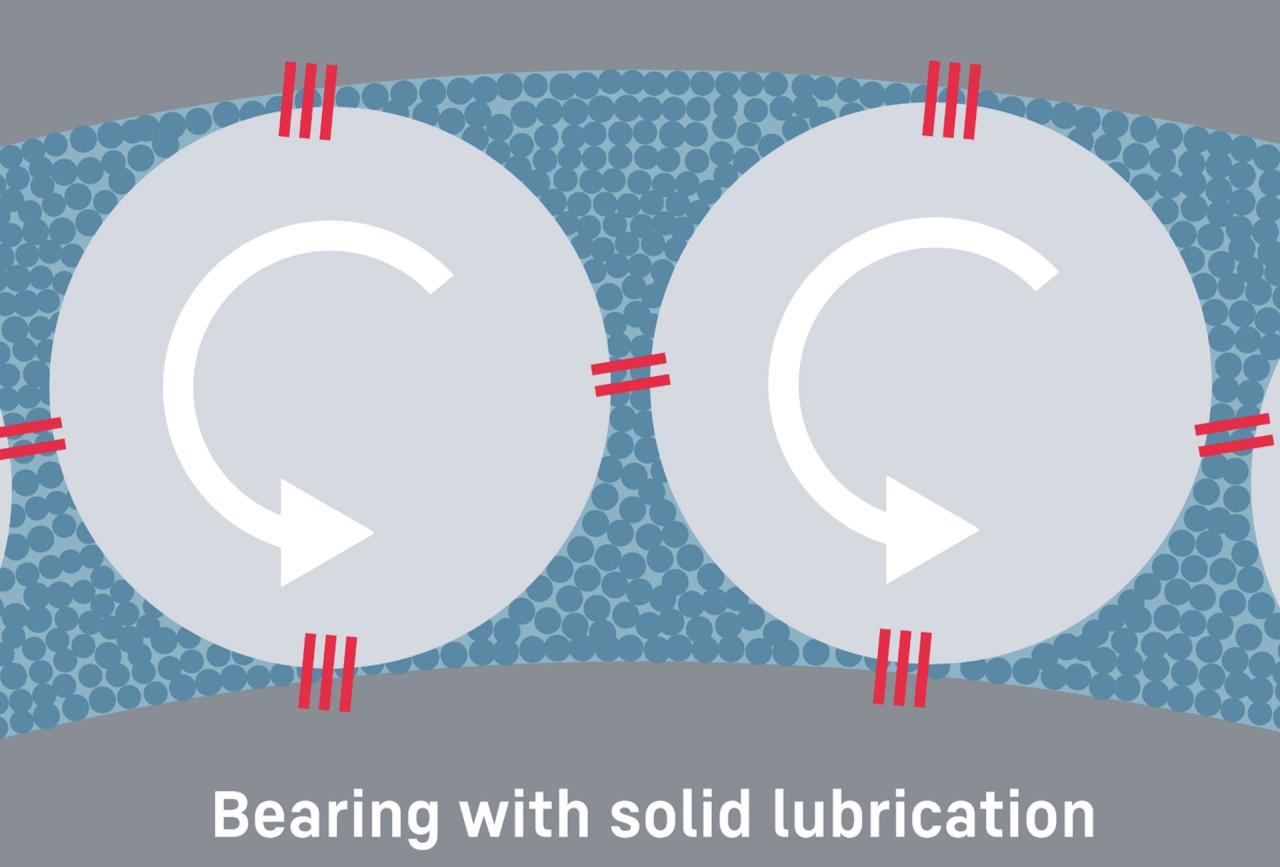

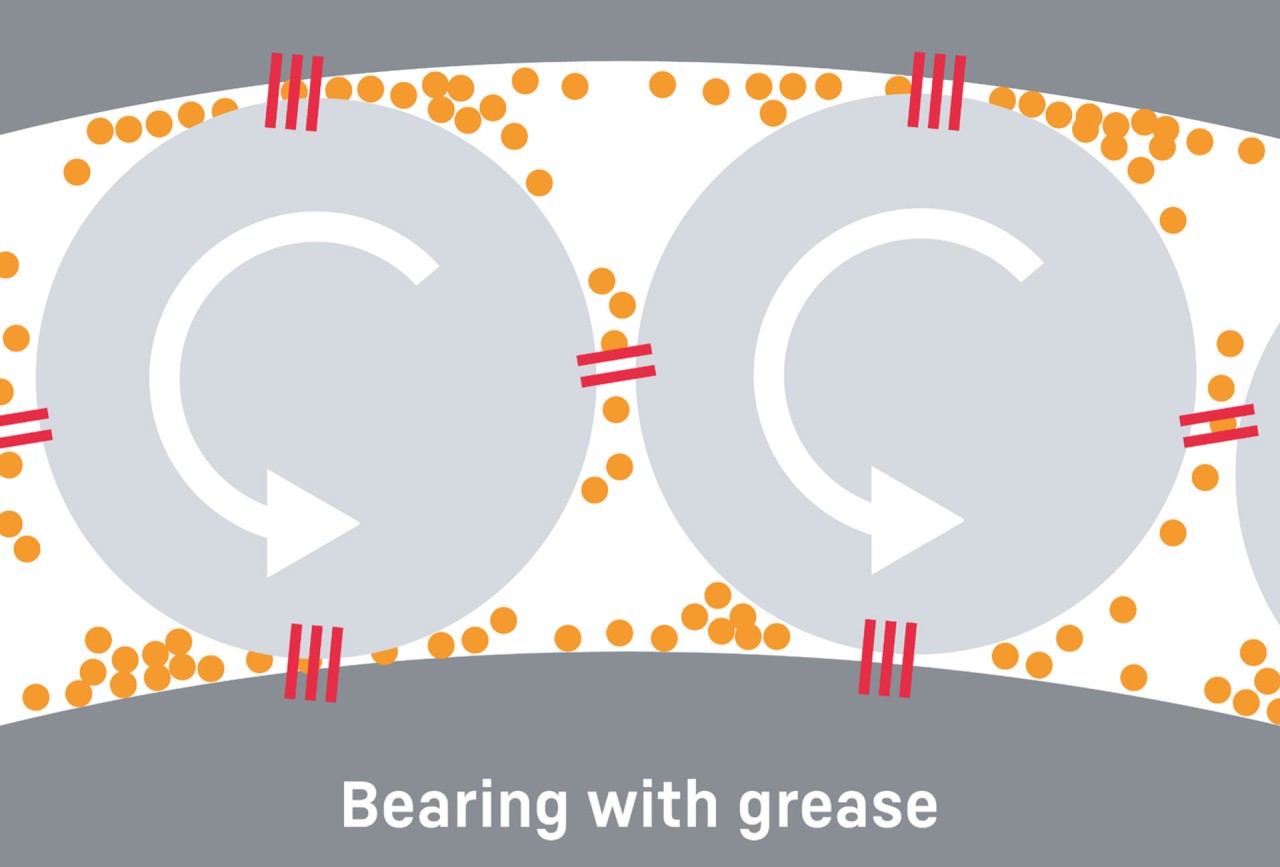

How does Lifinity work? It's simple yet ingenious. We introduce a liquid and heated polymer-oil compound into the heated slewing bearing. As the polymer cools and hardens within the bearing, it forms a durable lubricating layer that guarantees optimal performance. This innovative approach not only minimizes the risk of raceway corrosion but also eliminates the need for a time-consuming and costly relubrication system.

Solid lubrication: suitable for a wide range of applications

Wind energy

- Optimum characteristics of compound during high forces and low dynamic

- Improved protection in regard of standstill marking due to oil lubrication

Mining and earth moving

- No risk of insufficient lubrication due to empty grease system or damaged clogged piping

- Improved sealing

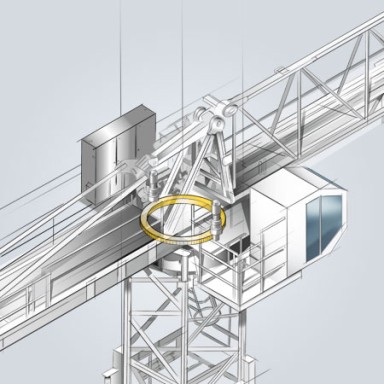

Tower cranes

- Less condensation and risk of corrosion due to maximum filling of the raceway

- No grease leakage, no environmental contamination

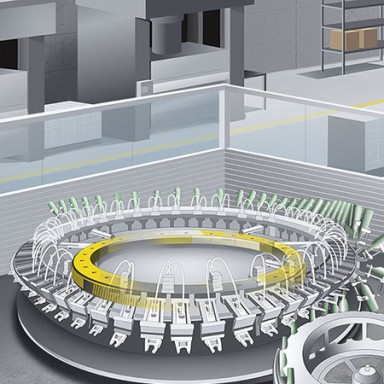

Bottle filling machines

- Long operating time, high turning speed

- Suitable for food industry: NSF/H1-approval

Lifinity is available for the following products:

Get in touch

Contact our local sales team or follow us on our LinkedIn channel.