LCS 600 - 1200

Large dimensions. Fantastic technology.

Generating grinding up to module 14mm

Generating grinding workpieces up to 1,200mm in workpiece diameter

Workpiece automation up to a workpiece diameter of 800mm and a workpiece weight of 1,000kg

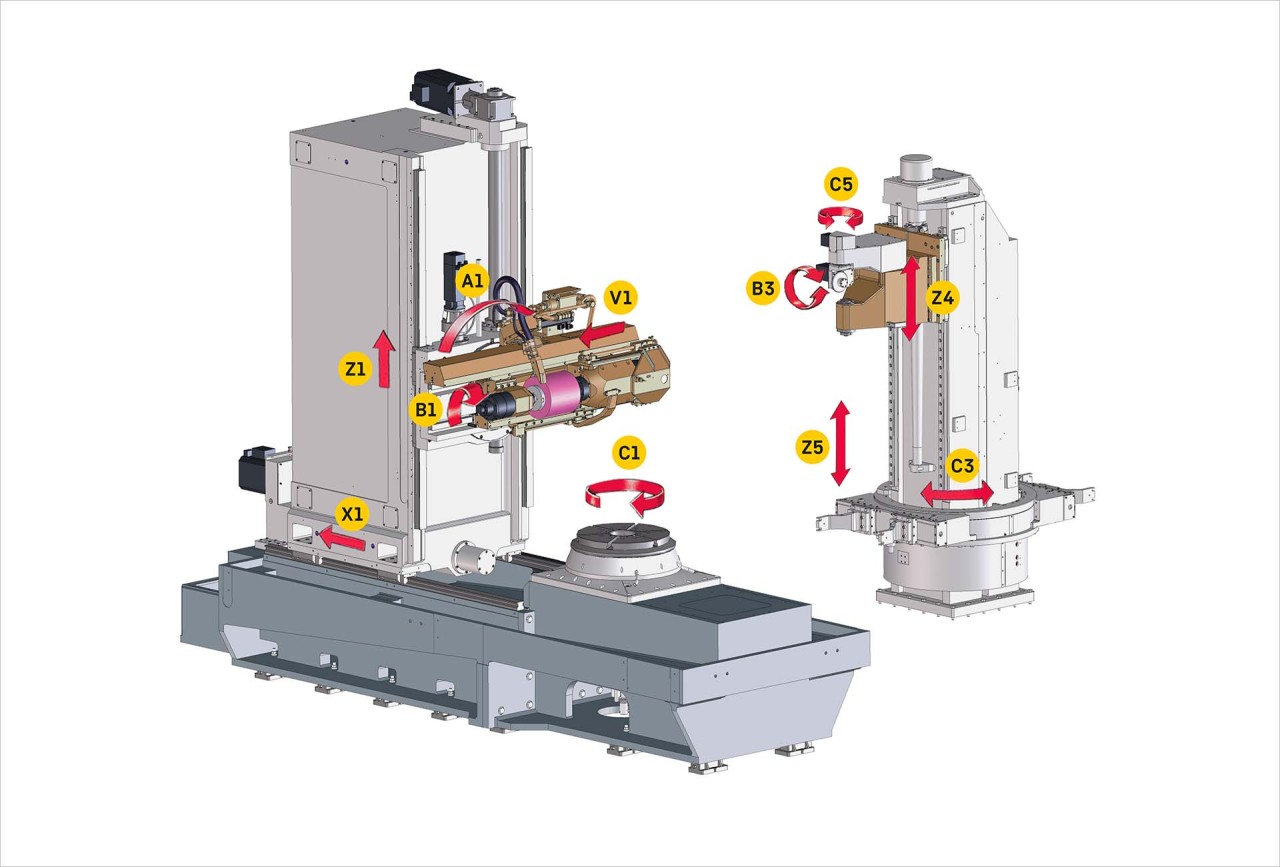

Machine design

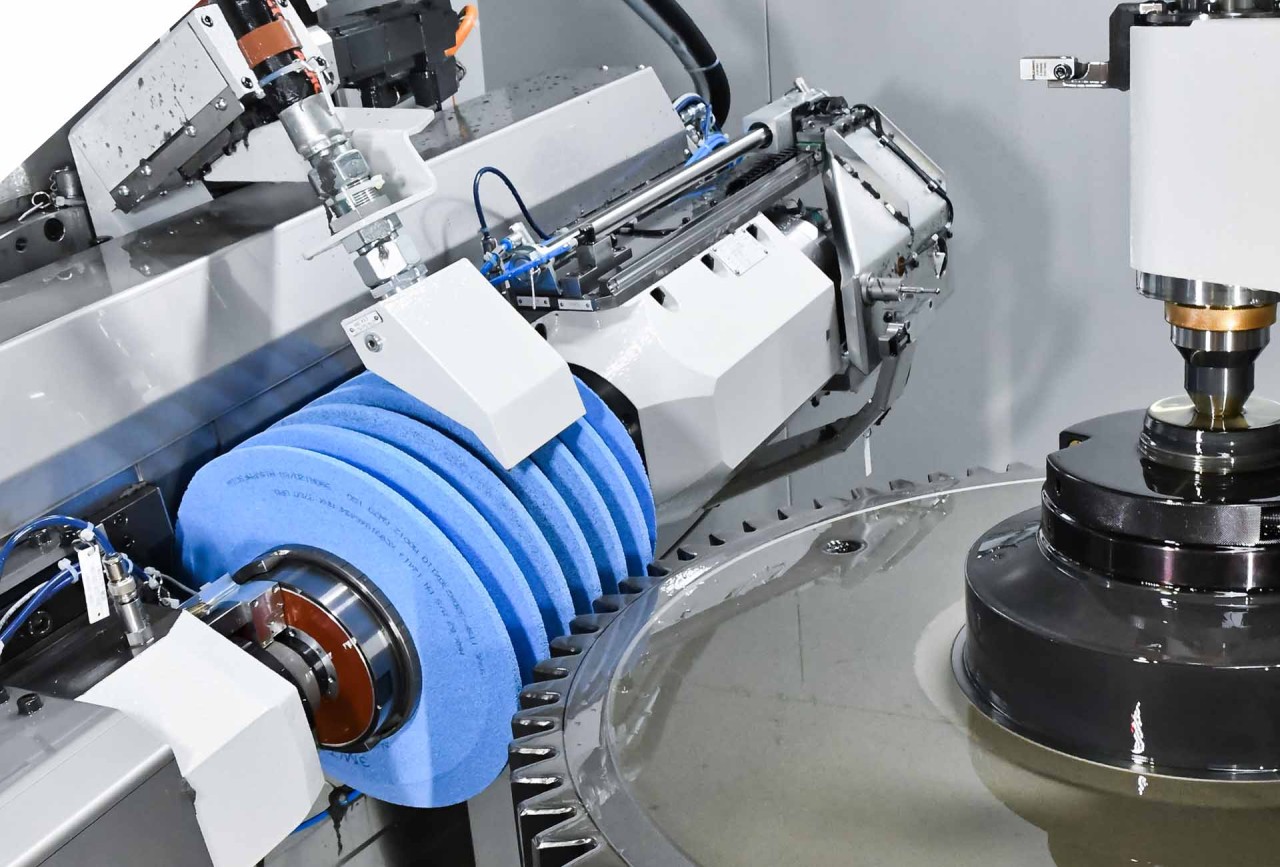

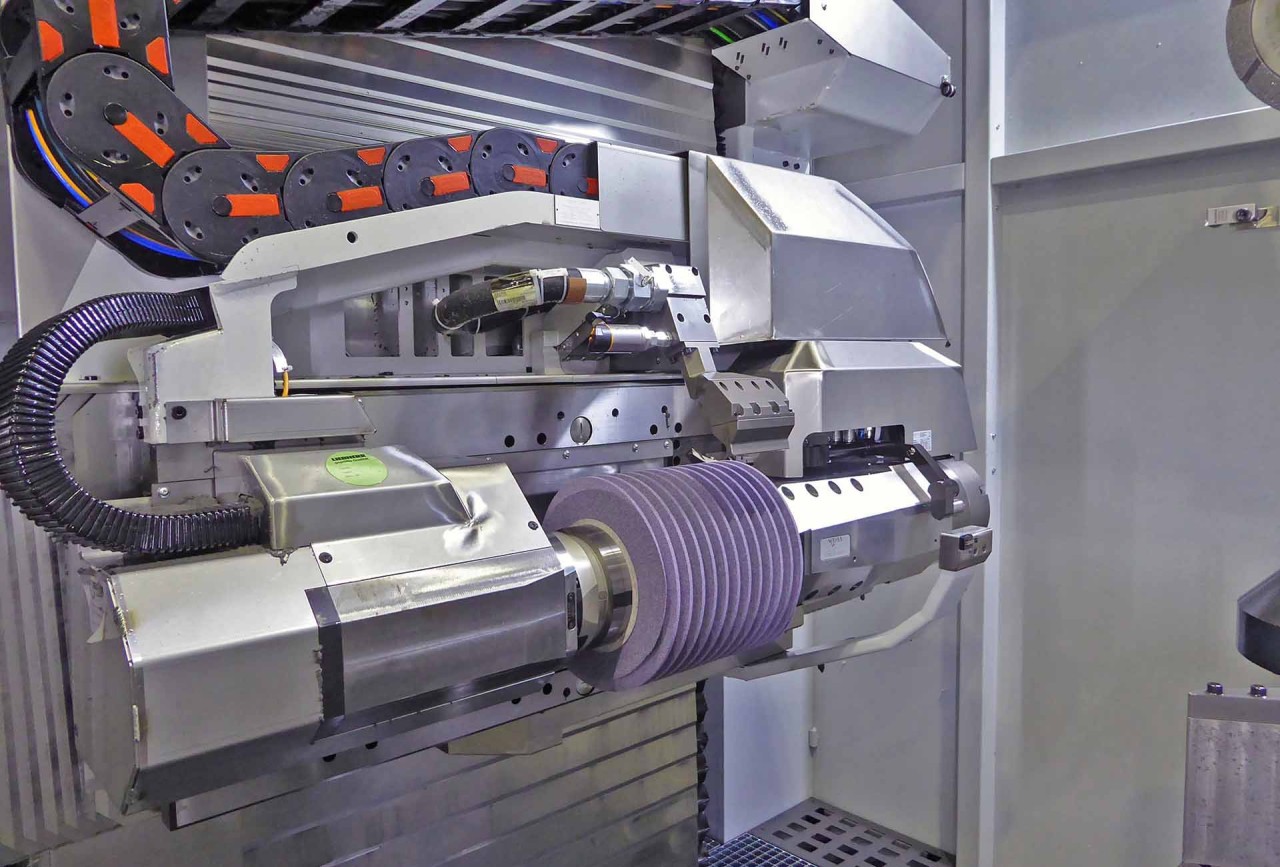

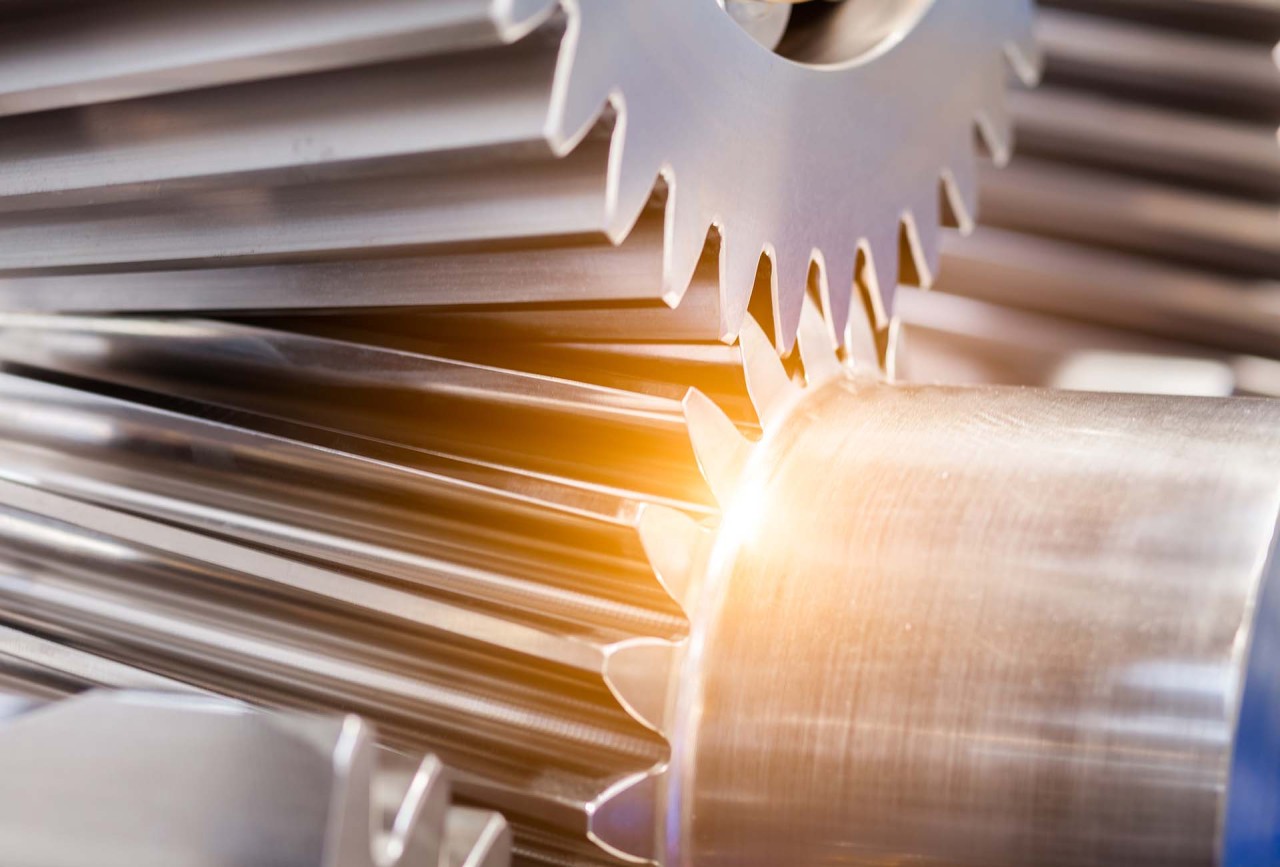

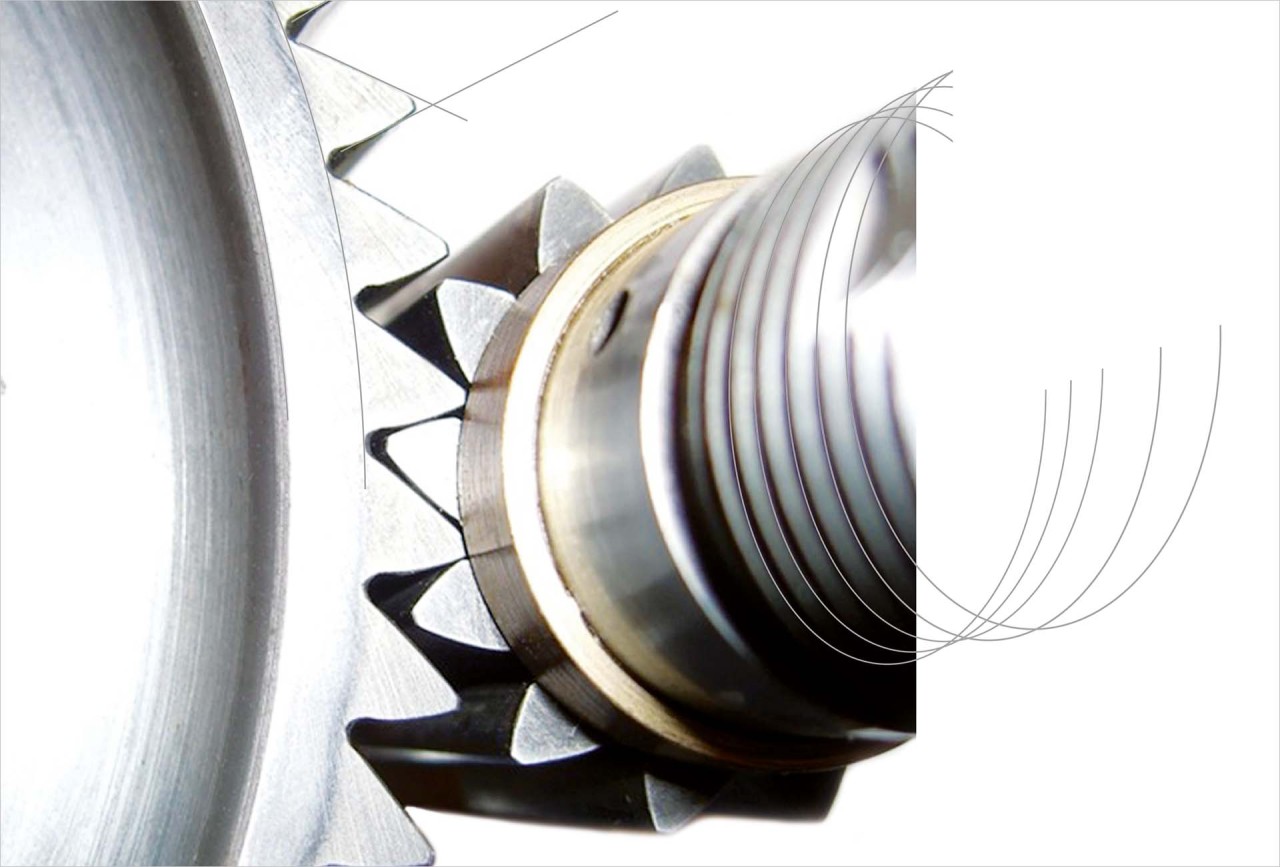

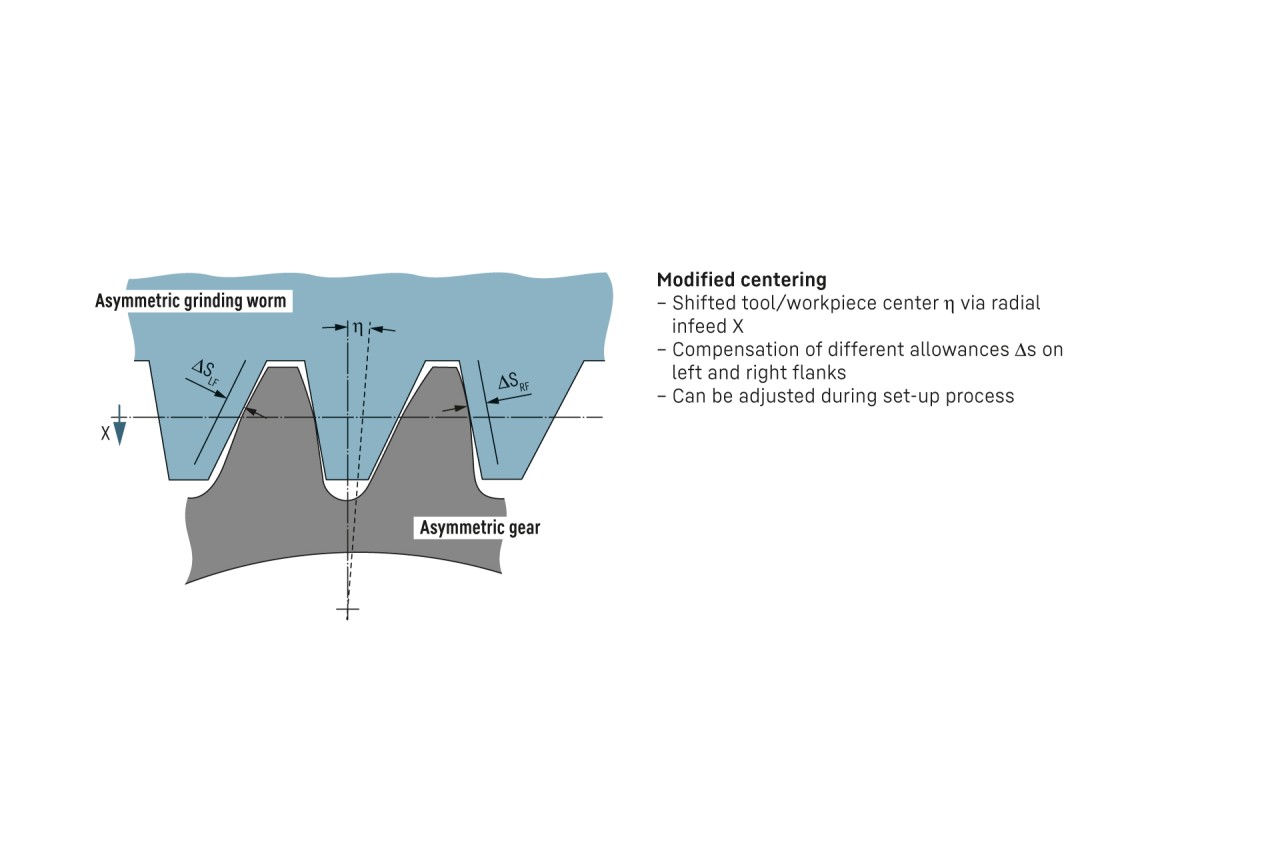

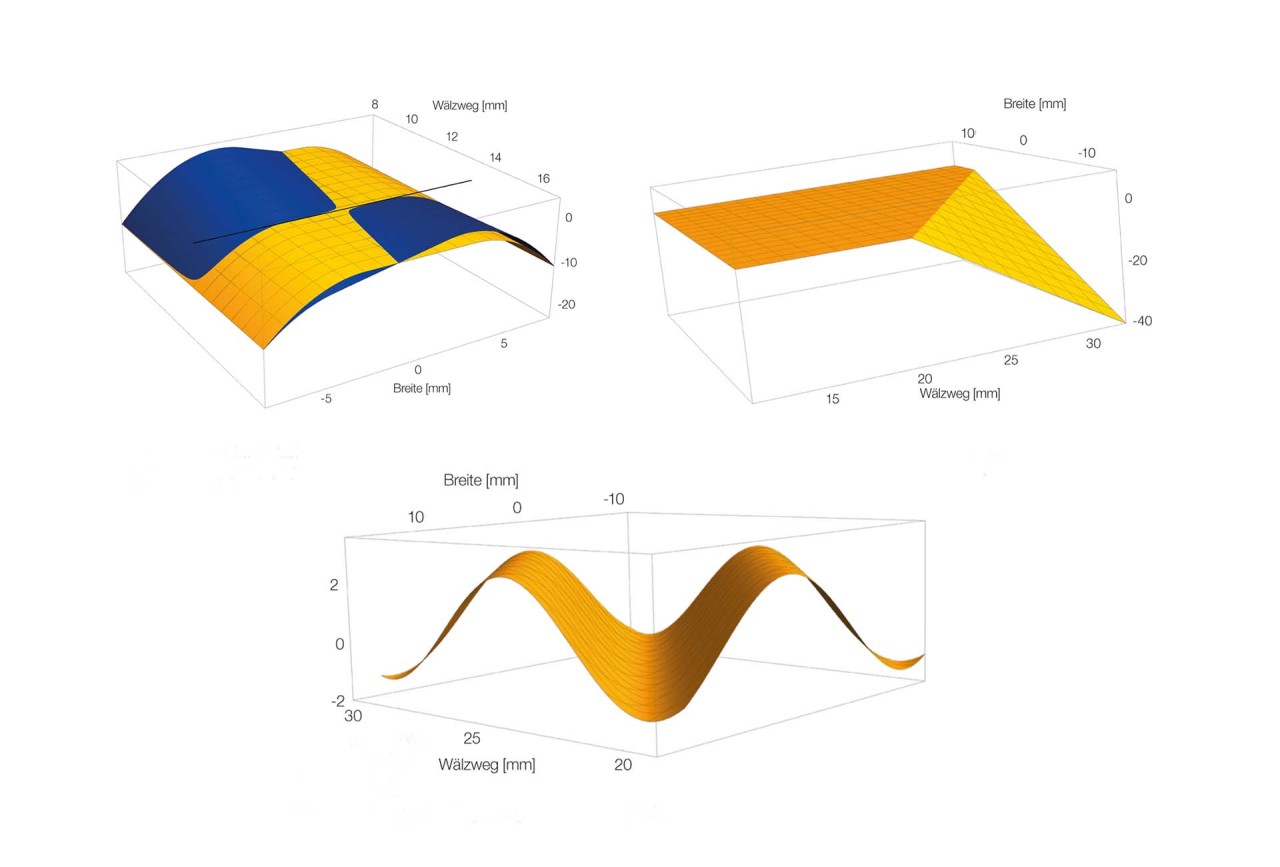

The new LCS Series 3 provides a machine system for the hard-fine machining of gears, which is characterized by its outstanding efficiency and versatility: generating or profile grinding with dressable or electro-plated CBN tools.

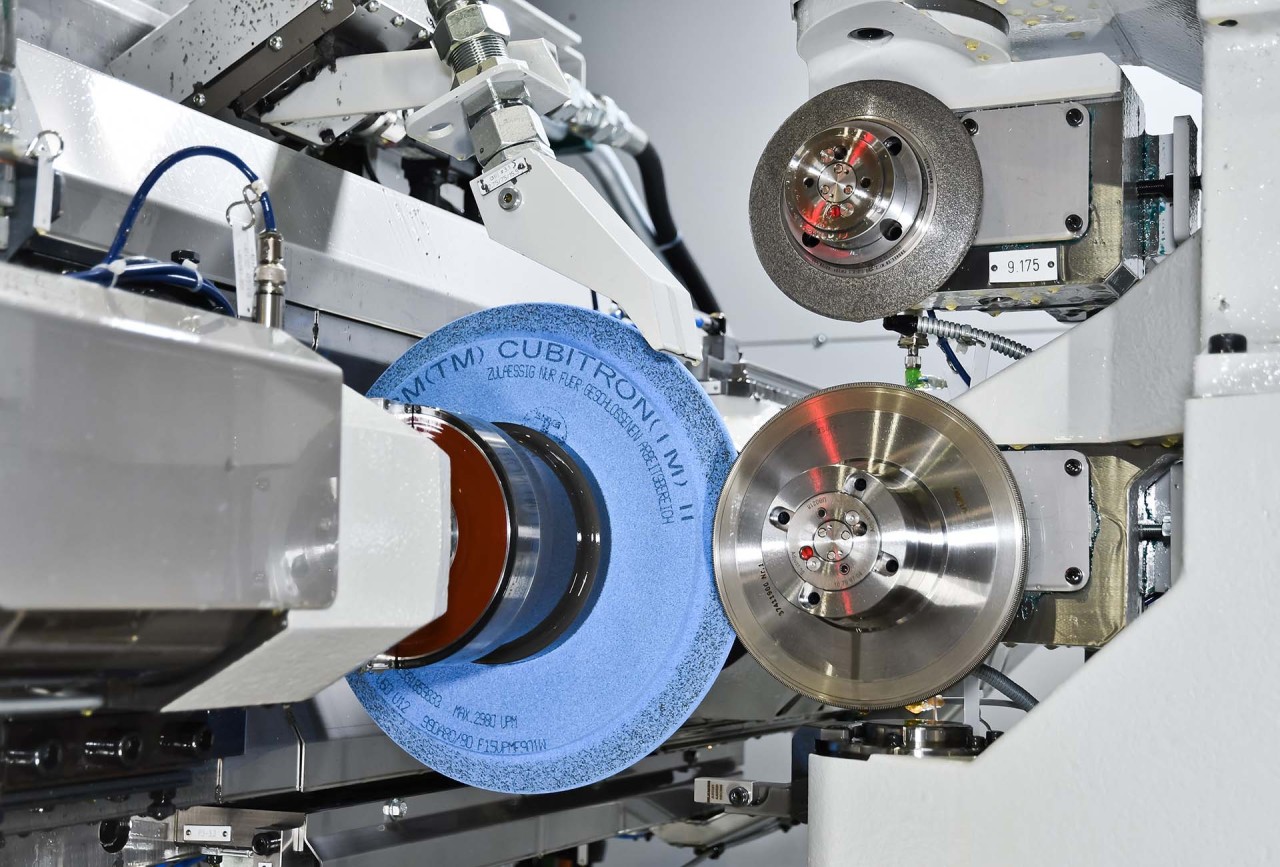

Gear grinding with dressable worms or discs has been a successful and well established technology for many years. Today, with the use of sintered corundum tools, it has reached a remarkable performance level.

With the LCS series, Liebherr enables the user to use both technologies without limitation, unlocking completely new possibilities in particular generating grinding the sorts of larger gears used in the wind power industry, for example.

Application examples

Video

Generating grinding large modules on the LCS 700 generating and profile grinding machine

Dressing, grinding and loading on the LCS 600 generating and profile grinding machine

Video

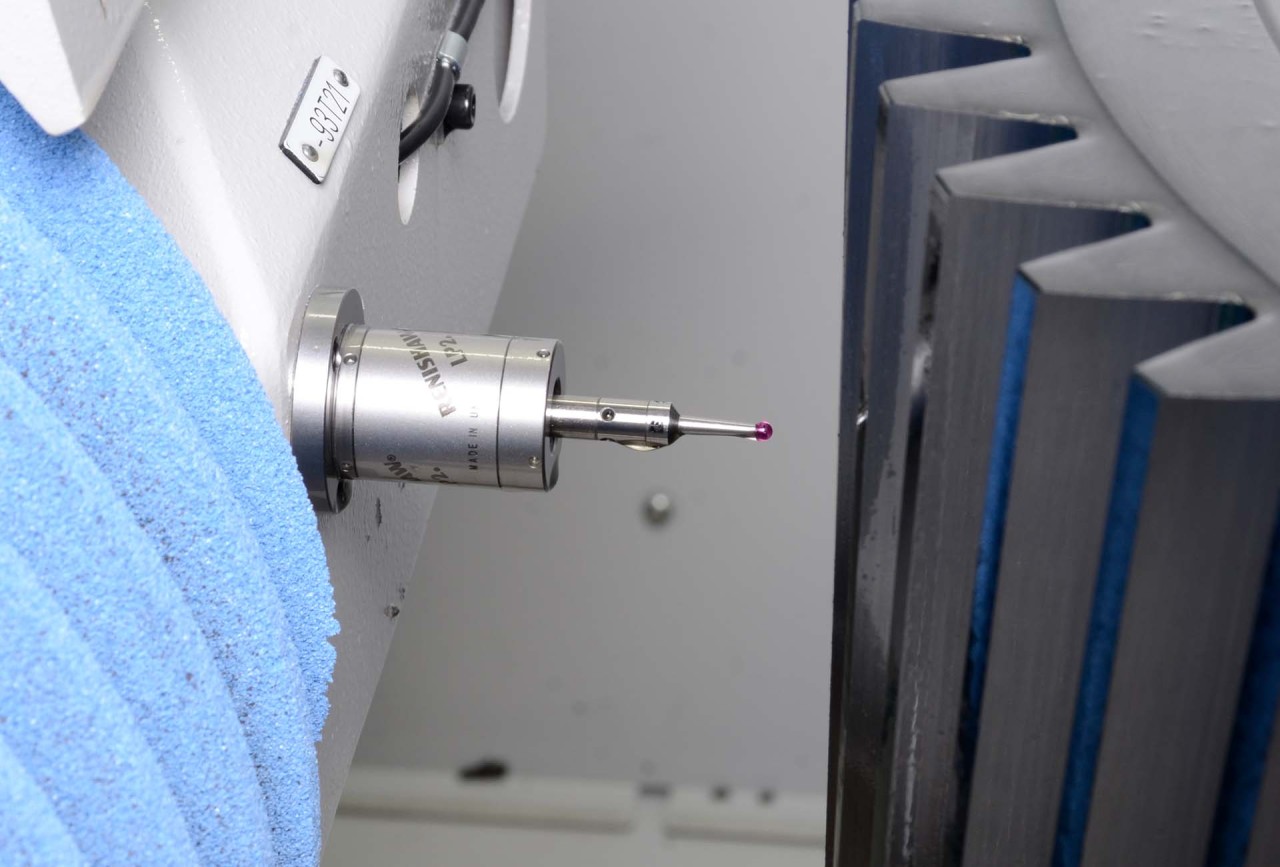

On-board inspection on the LCS 600 generating gear grinding machine

Technology

01/02

Video

Generating grinding and dressing on the LCS 800 generating gear grinding machine

Automation

Available for LCS 600, LCS 700 and LCS 800

Technical data

| Axial travel | 1,450 mm |

| Min. position above table | 200 mm |

| Grinding head swivel angle | 45 ° |

Variants

| Variants | LCS 600 | LCS 700 | LCS 800 | LCS 1000 | LCS 1200 |

|---|---|---|---|---|---|

| Workpiece diameter (mm) | 600 | 700 | 800 | 1,000 | 1,200 |

| Workpiece speed (min-1) | 350 | 350 | 250 | 250 | 250 |