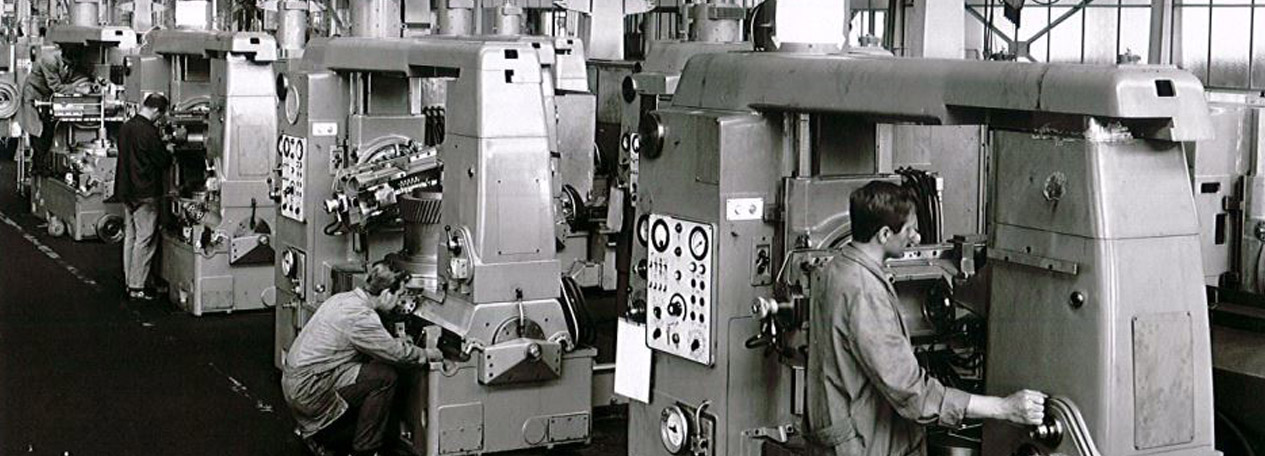

Pioneers in gear manufacturing

Pioneering achievements in gear technology include the first shaping machine with a hydrostatic guide in 1967 and the first gear grinding machine with CBN grinding discs in 1989. Both technologies set standards in their industry. Three years later, Liebherr took over the machine factory Lorenz, a renowned manufacturer of gear shaping machines and gear cutting tools located in Ettlingen. Liebherr Verzahntechnik still has a factory for gear cutting tools there today. The product range offered by the traditional company was a perfect fit for the Liebherr-Verzahntechnik product portfolio.

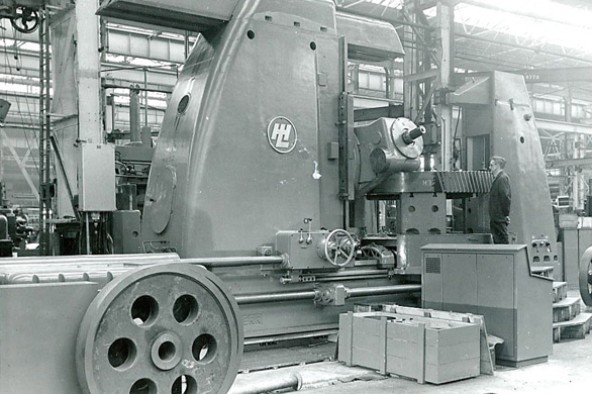

In the late 1990s and 2000s, the trend in gear technology was towards size: The wind turbine boom increased the demand for large toothed gears and therefore for machines to make them. Gears with a diameter of six metres required special technologies, which Liebherr successfully developed.

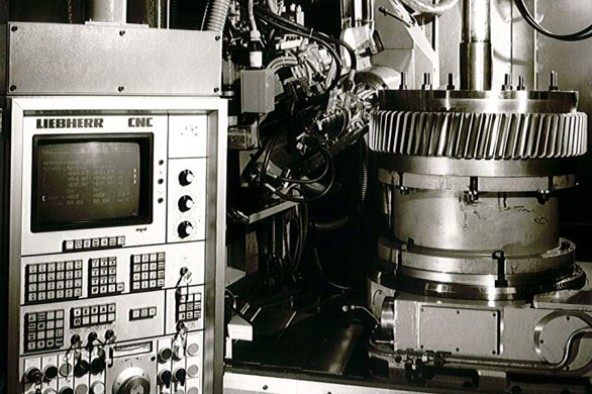

At the pulse of technological progress

In the last ten years, increased quality and precision of toothed gears finally came more sharply into focus, driven by aviation technology and the desire for increasingly quiet gearboxes. Gear technologies such as ChamferCut were able to score highly here. Gear skiving, a process that had been developed at an earlier date, finally caught on in a modern design and is having a considerable effect on productivity: skiving3 completes the product range of gear manufacturing.

Networking means building bridges

One aspect of this, according to Dr Hans Gronbach, is that “Modern technology increasingly uncouples people from machines. Previously, gears were set; now, everything is done through the digital NC control system. Perhaps our machines will be controlled from the office in future.” Direct feedback from the machine to human interventions is increasingly omitted. The operator cannot observe so directly and has to fill this gap by making inferences – a demanding task.

For Liebherr, this means a different way of interacting with employees. Michael Messer says: “We have to guide our people and train them appropriately. We therefore also see ourselves as bridge-builders for our employees towards globalisation and high technology.”

As Michael Schuster shows, this path already starts during training. “All trainees go abroad. Every industrial mechanic learns English and deals with control technology. This is an investment in the future. Interdisciplinary work is trained from the start, in order to encourage common understanding when working in teams.”

Intensive customer understanding

Intact and trust-based customer relationships have top priority for Dr Christian Lang. “We succeed because of our deep understanding of applications. Gear technology is now established, which means that the competition has become tougher. In this setting, trust in the ability to solve problems becomes increasingly important, because customer technological challenges are becoming ever more demanding.”

Quality is therefore the constant factor underlying Liebherr’s self-image. “This applies both to mechanical and digital products”, emphasises Dr Hans Gronbach. “Our daily routine and our development are becoming more and more software-dependent. That’s why we are increasingly building up expertise in this field and deciding where we should be active ourselves and where we should buy services.”

Needs-orientated and local production

Despite globalisation and digitalisation, however, Dr Christian Lang also sees a trend back towards local production. “We will experience a reversal. On the one hand, transport will be more expensive, and on the other hand, the modern factory requires fewer people – and those that are needed must be well trained. Thus, much of production will return from low-wage countries. The topics of the future are increased connectivity as well as needs-based and local production with the least possible waste, because resources are limited. We are preparing ourselves for these trends.”

To ensure that Liebherr gear technology and automation systems continue to be future-orientated, innovative and successful for the next 50 years to come.