The main focus of Great Taiwan Gear Ltd. is the production of gears and assemblies for alternative drives, such as EV (Electric Vehicle) and Hybrid systems. This new generation of transmissions requires very high gear accuracy – ranging from DIN four to five – as well as bias control. “Our willingness to develop new components together with our customers is one of our strong selling points”, emphasizes Samuel Lin from Great Taiwan Gear. “We are proud that the leading EV manufacturers choose to work with us.”

Satisfied customers speak for themselves

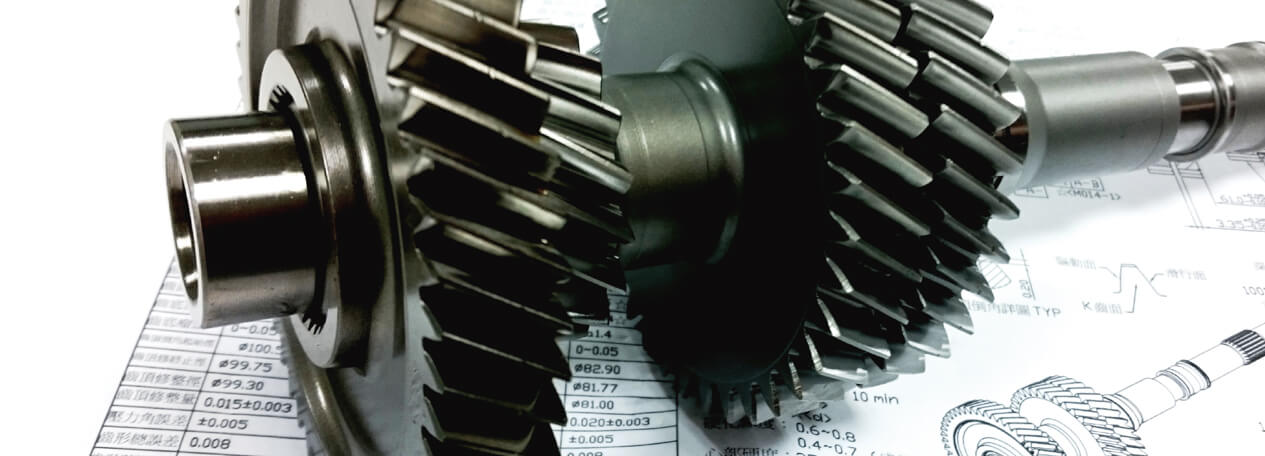

E-cars are very demanding in terms of gear quality. Great Taiwan Gear relies on Liebherr machines.

Close cooperation

To achieve the quality needed, the company works closely with its suppliers. The majority of our product development is the result of this cooperation – that is a particular feature of business in Taiwan. “Our partnership with international equipment and tooling suppliers is of equal importance”, says Samuel Lin. “Our partnership with Liebherr has helped us to find solutions and to meet the very high quality requirements of our customers.” The first Liebherr shaping machine the company purchased was an LS 120 gear shaper in 2010. Three LGG 280 gear grinding machines are now operating in the machine shop as well. The machines have performed very steadily and reliably since installation, which has even allowed inspection cycles to be shortened.

We especially appreciate the on-site support, which we receive from their service engineer team – from installation to final acceptance of the machines.

Twist-free grinding

Great Taiwan Gear focuses on superior quality: gear profile and lead tolerances are very tight. Most EV applications also require bias / twist control for twist-free grinding. The LGG 280 was the best choice for these requirements, Samuel Lin confirms. “We are satisfied. More importantly, our customers are also satisfied.”

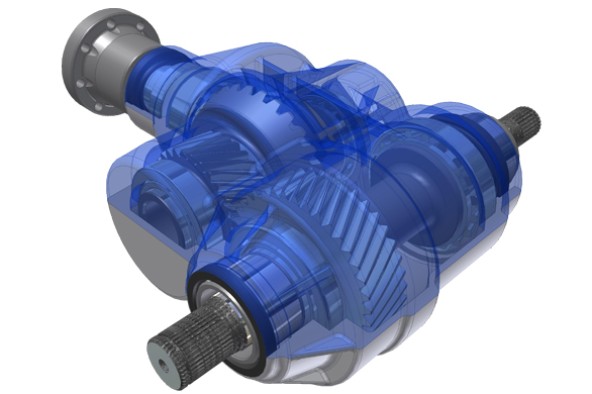

Liebherr developed a distortion-free grinding method for tooth-lead modifications, which is unique in grinding technology. “This is very important in terms of noise levels and size”, Heribert Tichatzki, Sales Manager Asia at Liebherr Verzahntechnik GmbH, explains. Noise Excitation Optimised Modification (NEO), Generated End Relief (GER), Deviation Free Topological Modification (DFT) are but a small range of possible micro-geometrical forms, which can be easily produced by Liebherr’s LGG machines. Transmissions are getting smaller and electric drives are much quieter than combustion engines. So the need to reduce the noise emitted by gears is obvious. Twist-free grinding can solve this problem and is in major demand in the EV-sector.

Company President Morley Lin

A worthwhile investment

The purchase of new gear grinding equipment was one of the largest investments made by Great Taiwan Gear. But the effort paid off: The set-up of the machine is straightforward and the users are very pleased with the reliability of the machines, especially considering the extremely tight tolerances involved. Following these positive experiences, discussions about further investments have already started.

Samuel Lin appreciates the service quality provided by Liebherr: “Liebherr is very professional and also understands the challenges of meeting very high quality specifications. We especially appreciate the on-site support, which we receive from their service engineer team – from installation to final acceptance of the machines.” A further advantage from his point of view is that Liebherr can offer application engineering support to solve issues, which can occur during ramp-up or production. “This team is also of great help to us in optimizing our gear machining processes.”