Clear vision of the future

Liebherr sets new standards, e.g. with the digitalisation campaign in the field of refrigeration and freezing and 3D printing in the field of hydraulic components. Liebherr products are put into action in exciting and spectacular projects around the world.

Liebherr-Hausgeräte presents the intelligent refrigerator of the future at IFA 2016.

2016 The intelligent refrigerator of tomorrow

True to its slogan ‘Making your life smarter’, Liebherr-Hausgeräte showcases the intelligent refrigerator of the future at the 2016 International Electronics Fair (IFA). SmartDevice is the name of the digital technology for networking refrigerators and freezers, which was developed in cooperation with Microsoft. It enables the customer to interact with their Liebherr refrigerator and opens up new dimensions in healthier food storage and innovative food management. For instance, the customer can control their refrigerator via an app, detect food stored in the refrigerator with the camera’s object detection and compile stock lists and new shopping lists.

Game on: The German and Austrian national teams during the match in the Liebherr mining truck.

2016 Match in the pit: Table tennis in the mining truck

Liebherr organises a special type of table tennis match at Bauma, the world’s largest trade show for construction machinery, in Munich. In the 130 m³ pit of a 165 tonne Liebherr mining truck, the German and Austrian national teams battle it out in a show-stopping game. Top players such as Timo Boll, Bastian Steger and Patrick Franziska from the German national team enjoy exciting rallies against Werner Schlager, Chen Weixing and Stefan Fegerl from Austria. For over 25 years, Liebherr has been actively involved in table tennis and is a strong partner of the German Bundesliga team TTF Liebherr Ochsenhausen, as well as the German and Austrian national teams and the International Table Tennis Federation (ITTF).

2016 Liebherr products used worldwide

Liebherr machines are used all over the world in large-scale projects. For example, ten tower cranes help in the construction of Europe’s tallest building, the 462-metre high Lakhta Tower in St. Petersburg. In the completion of the Elbphilharmonie concert hall in Hamburg, a mobile crane dismantles four tower cranes, which were used on site for many years. In Rostock, two mobile harbour cranes erect an offshore crane directly on the Giant 7 – a massive heavy-goods carrier. Trams in San Francisco, in the USA will be equipped in the future with hydraulic steering springs from Liebherr. With the delivery of the first tunnelling bearing for a tunnelling machine, the Components division also conquers the American tunnel construction market.

2016 Organisational realignment in the USA and opening in Biberach an der Riss

In June, Liebherr-Components Biberach GmbH opens a new subsidiary plant for the development and production of switchgear, as well as electric motors and alternators, in Biberach (Riß). New development and production facilities are located on an area of roughly 14.5 hectares. Liebherr invests in the expansion of the Components division.

In the same month, Liebherr USA, Co. commences work. The new mixed sales and service company is responsible for the maintenance of products from a total of eight divisions in North America. This organisational realignment should further improve customer support.

Spoiler actuator with valve block from the 3D printer developed and manufactured by Liebherr-Aerospace.

2017 World premiere: A380 flies with 3D-printed hydraulic components

In March 2017, an Airbus A380 flies for the first time with a spoiler actuator valve block from the 3D printer of Liebherr-Aerospace. Never before was a hydraulic component of the primary flight control system, which was manufactured additively from titanium powder, used in an Airbus. The titanium valve block assumes important functions on board the A380, e.g. during the manoeuvring of the plane and decelerating after landing. The 3D-printed component acts like a traditional, forged valve block, but offers two decisive advantages: It is 35 percent lighter and consists of fewer individual parts.

2017 Diverse product applications from Bregenz to Kuala Lumpur

Also in 2017, Liebherr products are used worldwide. For example, two tower cranes install the stage set for the Bregenz Festival. In Paris, a mobile crane lifts a five tonne and 18 metre long sailing boat onto the first level of the Eiffel Tower. Through the action, attention is drawn to a French physicians’ initiative, which makes possible life-saving heart operations for children all over the world. On the east coast of Scotland, more than ten different types of mobile cranes and products from three business segments assist in the construction of the world’s longest suspension bridge. Ten cable excavators and crawler cranes work on a multi-billion infrastructure project on the Suez Canal in Egypt, one of the most important waterways for world trade. In the Malaysian capital Kuala Lumpur, the largest Liebherr rotary drilling rig is involved in the sought-after residential project “Sentral-Suites”.

Largest crane since 1949: The special ship “Orion” is equipped with the HLC 295000.

2017 Liebherr builds largest crane since company’s foundation

It is used to install wind farms and to dismantle offshore facilities for the oil and gas sector and will be the biggest crane ever built by Liebherr: The HLC heavy-lift offshore crane. In 2017, Liebherr receives the award for the delivery of the heavy-duty crane for the “Orion” ship. The giant can lift loads of up to 3,000 tonnes 170 metres high with a jib length of 50 metres.

The 50,000th wheel loader comes off the production line in Bischofshofen in April.

2017 Anniversary machines – Gold instead of yellow and graffiti art instead of paint

In April 2017, in Bischofshofen the 50,000th wheel loader, a L 566 XPower®, comes off the production line. With golden paintwork, the Liebherr Group and the long-term Liebherr customer celebrate the wheel loader anniversary. An A 918 Compact Litronic wheeled excavator also becomes a canvas for the delivery of the 75,000th excavator. Because the street artist Claudia Walde alias MadC designs the anniversary machine with colourful graffiti art.

Green energy construction site in Gaildorf surpasses the Swabian Alb.

2017 Liebherr machines play their part in the energy revolution

One of the most exciting future pieces of the energy revolution is located near Schwäbisch Hall. In the pilot project “Naturstromspeicher Gaildorf” wind turbines in combination with a decentralised pumped-storage power plant make green energy storable for the first time and also available flexibly. Liebherr machines assist the project, which at the same time gives rise to the world’s tallest onshore wind turbines at 246.5 metres.

2017 Liebherr further invests in production facilities and the sales and service network

In 2017, Liebherr invests around €749 million in the production facilities and the global sales and service network. For example, the opening of the 2,500 m² hall at the Reman Competence Centre of Liebherr-Ettlingen GmbH takes place in April. Just two months later, the new construction of the development and demonstration centre starts in Kirchdorf an der Iller with the groundbreaking ceremony. In order to support customers even more efficiently in the rail transport area with customised services, a new service outlet of Liebherr-Transportation Systems opens in Switzerland in September.

First ‘green’ air-conditioning system ‘Eco-Clim’: excellent passenger comfort and low maintenance costs.

2018 ‘Eco-Clim’ air-conditioning system for environmentally friendly rail traffic

Following a two-year test phase, the first ‘green’ air-conditioning system, ‘Eco-Clim’, proves itself in a regional train operated by French railway company SNCF. The environmentally friendly air-conditioning system works without any chemical refrigerants. Instead, airborne cooling technology is used, which has its roots in the aerospace industry. The technology does not cause any damage to the ozone layer, thus helping to combat climate change.

Minister of Transport Andreas Scheuer, Dr. Dietmar Woidke (Minister President of the State of Brandenburg), Federal Chancellor Dr. Angela Merkel, Dr. h.c. Willi Liebherr (President of the Board of Directors of Liebherr-International AG) and Delphine Gény-Stephann (State Secretary of the French Ministry of Economics) (from left to right) at the ILA booth of Liebherr-Aerospace.

2018 Federal Chancellor Merkel visits Liebherr at the ILA

Liebherr takes part in the International Aerospace Exhibition (ILA) in Berlin from 25th to 29th April, 2018. Special highlight: visit from Federal Chancellor Dr. Angela Merkel at the booth of Liebherr-Aerospace. She is accompanied by the Minister of Transport Andreas Scheuer and Brandenburg’s Minister President Dr. Dietmar Woidke. Minister of Economics Peter Altmaier and Thomas Jarzombek, Federal Government Coordinator of German Aerospace Policy, are among some of the other prominent guests from the worlds of business and politics.

Record revenue: Liebherr reaches the 10 billion euro mark in 2018.

2018 Liebherr’s annual revenue passes 10 billion euros for the first time

The Liebherr Group exceeds the ten billion euro mark for the first time in its history with a revenue of 10,551 million euros in 2018. Compared to the previous year, Liebherr achieves a total increase of 739 million euros or 7.5 percent. Revenue for the divisions producing construction machines and mining equipment increases 10.8 percent to 6,833 million euros. This includes in particular the Earthmoving, Mining and Mobile Cranes divisions. In the other product areas, those covered by the maritime cranes, aerospace and transportation systems, gearing technology and automation systems, domestic appliances, components and hotels divisions, the revenue increased 2 % to 3,718 million euros. To go to the 2018 annual report, please click here.

2018 Investments of over 800 million euros in production, sales and services

Liebherr-Components Kirchdorf GmbH opens a new factory for hydraulic cylinders in Oberopfingen (Germany) in April. Two new factory halls for logistics, assembly, testing and paintwork of hydraulic cylinders are built on an area of 23,000 square metres. Just one month later, Liebherr also opens a 20-hectare production site in Aurangabad (India). Liebherr Appliances India Private Limited specialises in the manufacture of high-quality refrigerators and freezers for the Indian market. In June, the construction of the new Liebherr sales and service centre in the port of Hamburg begins. The Hamburg-based subsidiary will look after mobile harbour cranes, ship cranes and offshore cranes, as well as construction machines. In the same month, the groundbreaking ceremony for a new logistics centre of Liebherr-Hydraulikbagger GmbH takes place in Kirchdorf an der Iller (Germany). And, in July, the construction of the new head office of Liebherr USA, Co. starts in Newport News (USA). The investment of around 45 million US dollars should drive the long-term growth of Liebherr in the USA.

2018 Liebherr products in action all over the world

Also in 2018, Liebherr products are once again in use all over the world in trend-setting projects, e.g. on Europe’s largest construction site “Grand Paris”. The 21st century project should prevent gridlock in the French capital and will continue until 2030. In Germany, Liebherr installs one of the most powerful land-based heavy-duty cranes in the world at the port of Rostock in order to make possible the loading of heavy loads from in-house production and external handling of heavy-duty cargo. Around 1,000 km away as the crow flies, a Liebherr cable excavator assists in the expansion of the Jätkäsaari peninsula in Finland. A new district with apartments for around 21,000 people is being built south of Helsinki. Liebherr delivers another project with the Norwegian crane operator OHT: The HLC 150000 heavy lift crane is used on a ship for installation foundations for a wind farm. The installation ship with a lift capacity of 48,000 tonnes can submerge in operation, which increases the stability of the crane. Because of this the HLC withstands a variety of environmental scenarios, thus enabling use in almost all types of weather. And Liebherr products are also active in Santiago de Chile in South America. For instance, 23 tower cranes are used to expand the airport by 265,000 square metres, incorporating an additional terminal and doubling the number of parking spaces. All this happens without any interruption to flight operations.

Awarded Gault&Millau toques: Thomas Carvalho de Sousa (left) and Mario Döring (right) won several Gault&Millau toques.

2018 Chefs recognised with awards

The restaurant guide Gault&Millau awards chefs from two Liebherr hotels. Thomas Carvalho de Sousa (left) wins two of the coveted Gault&Millau hats for the Löwen Hotel Montafon in Schruns (Austria) and Mario Döring (right), chef at the Interalpen Hotel Tirol (Austria), was awarded three hats. Apart from the Michelin stars, the Gault&Millau hats are the most coveted awards in haute cuisine.

2019 Liebherr products for transport and renewable energies

Since January 2019, Boeing’s 787 Dreamliner aircraft has been fitted with the Remote Electronic Unit. This represents an important milestone in Liebherr’s strategy for stand-alone electronic components.

At the Brenner Base Tunnel, two Liebherr mixing plants also play a part in the construction of the world’s longest underground railway link. This is particularly challenging due to the heterogeneous rock composition in the tunnel.

A Liebherr product is also involved in the expansion of a motorway junction in Austria. This saw a world first in the deployment of the LB 16 unplugged. It is the first battery-powered large rotary drilling rig and produces almost no emissions.

A prototype of the world’s most powerful offshore wind turbine is built in Rotterdam. This involves the 780-tonne machine house being lifted to a height of over 150 metres by two LR 11350 crawler cranes. Never before has such a heavy load been lifted to such a height by Liebherr crawler cranes.

Based on three jobsite models, users can get to know how the crawler cranes, cable excavators and deep foundation machines all work.

2019 Liebherr AR Experience – digitalisation you can touch

With the Liebherr AR Experience, which can be downloaded as a free app for smartphones and tablets, digital 3D data is projected onto your actual surroundings with the help of augmented reality. Through the app, users can virtually jump into a building site and discover how the construction machines work.

2019 Liebherr continues to invest in 2019

In January, Liebherr-Transportation Systems (China) Co., Ltd. is founded with headquarters in Pinghu (China). The branch is focused on the manufacture of environmentally friendly air-conditioning systems, electrohydraulic actuation systems and high-performance cooling technology. In China, a Liebherr-Verzahntechnik production plant is also officially opened in May. China is one of the most important markets for top-quality gear cutting machines and automation systems.

In addition, Liebherr-Hausgeräte GmbH opens a new customer centre in Ochsenhausen (Germany) in June. On a site spanning more than 3,500 square metres, it incorporates not only new offices, but also exhibition space for the latest trends in refrigeration and freezing.

In September, Liebherr opens a new branch in the Port of Hamburg. The new site will serve customers of mobile harbour cranes, ship cranes, offshore cranes as well as cable excavators, crawler cranes and deep foundation attachment tools.

In the same month, a training and service centre is added to the Liebherr Mobile Cranes Korea Ltd. site. It is designed to meet the growing demand for local customer service.

INTUSI was developed together with the TUD Dresden University of Technology.

2019 Entering the new age of machine communication with INTUSI

The INTuitive USer Interface (INTUSI) is a highly digitised control console for construction machines and material handling machines. The operating environment, which can be adapted to situations and users, enables digital assistants to be integrated and represents the key to the concept of the networked construction site 4.0. The idea of this is to make work on construction sites safer and more effective.

Zero-emissions concrete transport with the Liebherr ETM 1205

2020 First all-electric truck mixers represent a milestone in concrete transport

Stepping away from the diesel engine: The ETM 1005 and 1205 truck mixers developed by Liebherr and Designwerk are an all-electric solution for transporting concrete. The two versions are fitted with 10 and 12 m3 drums respectively, and run on a five-axle chassis from Futuricum with the equivalent of 680 hp. The truck mixers cover the relatively short distances between the concrete plant and the construction site virtually silently and without producing any emissions, plus the energy recovered through braking or downhill driving increases the range. Overnight, the batteries of the vehicles can simply be recharged as needed using the charging infrastructure at the concrete plant, so they are ready to go the next morning.

Challenging off-road deployments are child’s play for the TA 230 Litronic

2020 The new generation of articulated dump trucks

The TA 230 Litronic with a payload of up to 28 tonnes is the first of a new generation of articulated dump trucks from Liebherr. The machine has been developed specifically for demanding off-road applications in overburden transportation and within the mining industry. The powerful six-cylinder engine with 265 kW/360 hp delivers impressive drive at maximum traction. The optimised 18.1 m3 capacity of the dump body boosts productivity and a newly developed driver’s cab ensures the best visibility. Modern assistance systems also support the machine operator, increasing their safety and comfort during operation.

2020 More than €600 million of investment in production, sales and services

In February, the Liebherr Panama S.A. mining company begins construction of its new headquarters in Panama City. The site will house an administrative office, a workshop for remanufacturing components and a spare parts warehouse. In July, Liebherr USA, Co. moves into its new headquarters on the campus in Newport News (Virginia). The 23,300 m2 expansion includes new offices, a training centre, a workshop and a new warehouse. In August, Liebherr celebrates the new opening of the Liebherr-Transportation Systems (China) Co. in Pinghu (China) The site develops, produces and maintains components and systems for rail transport in China and around the world. In the same month, Liebherr opens a monobrand store in Vienna: a 170 m2 site where customers can discover Liebherr’s entire range of refrigerators and freezers first hand.

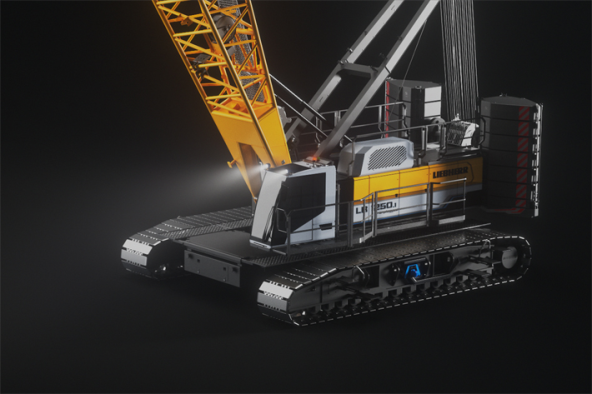

LR 1250.1 unplugged – a world first

2020 The world’s first battery-powered crawler cranes

With the new LR 1200.1 unplugged and LR 1250.1 unplugged cranes, Liebherr passes a milestone in the field of alternative drives: the world’s first battery-powered crawler cranes. Both cranes are driven by electric motors with a system output of 255 kW and have no loss in performance or usability when compared with the conventional version. The new units produce zero emissions and very little noise in operation, which is particularly advantageous in noise-sensitive environments. The electrical battery concept of the drive means the cranes can operate with power cables or without, i.e. ‘unplugged’, and can simply be recharged within a few hours from a conventional electrical outlet on the construction site.

2020 Liebherr products in action around the world

A spectacular journey by water unfolds in Colombia. An LTM 1220-5.2 mobile crane from Liebherr, weighing 220 tonnes, has to be transported to a remote forest region in the highlands of Colombia. It is floated by barge along the Rio Cauco River for eight kilometres to reach the secluded ‘Autopista pacífico 2’ construction site where it is needed to install a bridge.

In Switzerland, too, a special construction site requires a different kind of operation. A Liebherr LB 36 drilling rig is called upon for the renovation of a historic railway bridge in Koblenz, in the canton of Aargau. The rig does its work from a pontoon, erecting four bored piles for every bridge pier. The LB 36 was positioned using LIPOS®, the Liebherr positioning system for deep foundation machines, because spray cans won’t get you very far on this watery construction site.

An LHM 420 mobile harbour crane, which reaches Argentina completely dismantled, finds itself in a unique situation. Due to the restrictions caused by the pandemic, it is the first mobile harbour crane to be assembled remotely using the Liebherr Remote Service app before it is ready for action. Thanks to the extensive functions of the app and the close virtual cooperation between Liebherr-MCCtec Rostock GmbH (Germany) and Liebherr-Argentina S.A., the crane is ready for handover to the customer on time.