From the software package to the turnkey robot cell

Until now, Liebherr has provided Bin Picking solutions with software supplied by a partner. Now the company offers its exclusive software package with new features that can also be integrated into systems from other manufacturers. Liebherr’s combined expertise in software development and industrial application also makes LHRobotics an interesting product for integrators.

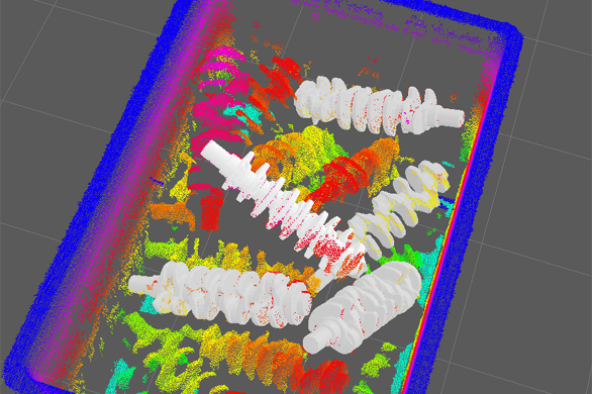

With Bin Picking, a robot must use a vision system to recognize objects, remove them without collision, place them in the correct orientation and transfer them to a machine. The software for this, the “brain” of the robot so to speak, was developed by Liebherr together with a leading research institute, but initially used exclusively on its own systems. In 2019, the decision was made in Kempten to market the software and to distribute it exclusively. Liebherr strengthened its technological competence with additional technologists and software specialists for vision systems and Bin Picking.

The software recognizes the arrangement of parts in the scan

New: simulation tool to optimize the gripper concept

The package consists of a camera, software and documentation. What is new is the optional simulation tool developed by Liebherr. With a virtual camera and a virtual point cloud, it simulates whether the gripper concept will work and enables the user to modify the gripper geometry and optimize processes in order to achieve better emptying of the bins. This feature closes a gap in the offline programming of the robot, because the entire process, including Bin Picking, can now be mapped virtually.

Integration in systems from other manufacturers possible

What is also new is that the LHRobotics software can be integrated in systems from other manufacturers. This makes it particularly interesting for system integrators. They now have available a fully developed product and can also draw on Liebherr’s system expertise. “We don’t just have the software – we bring our entire system expertise and industrial experience to the table. That’s pretty unique,” says Thomas Mattern, Head of Automation System Development. Many users trust Liebherr’s know-how when deciding on a Bin Picking system. “For many smaller plant manufacturers, Bin Picking is initially a very complex application. If they know that Liebherr is behind them, they’re more willing to tackle the topic,” continues Thomas Mattern.

Finalist in the ERF TechTransfer Award 2020

The software development project reached the finals of the European Robotics Forum (ERF) 2020 in Malaga, where outstanding innovations in robotics and automation resulting from cooperation between industry and research are selected.

Ready for future requirements

Bin Picking is not just limited to heavy machined components whose ergonomics make it necessary to use robots. The trend in Bin Picking is towards increasingly complex parts, such as chassis and body components, which have to be detected, evaluated and transported using sensor systems. There are also interesting applications for the technology in overall vehicle assembly. With its wide range of products – from software to robot cells to turnkey systems – Liebherr can always respond individually to the needs of its customers. “We’ll also be dealing with topics such as artificial intelligence (AI) and deep learning in the future, but together with our technologists and software specialists, we’re ready for anything,” predicts Thomas Mattern.