Mobile and crawler cranes

Mobile and crawler cranes

4 minutes | magazine 02/2021

Expert tip: crawling

Crawler cranes are primarily lifting units, but they are also ideal for manoeuvring on site.

Oliver Schwenkkrauß - Designer

How to crawl properly

The wind turbine is fully erected. The components for the next turbine are waiting to be erected 200 metres away. Hundreds of tonnes of steel start to move and the crawler crane crawls towards its next job. Dozens of turbines will be erected at this wind farm which is just one of many around the world.

Crawler travel gears are designed for moving cranes on sites, sometimes even with a full load on the hook. And this is precisely where crawler cranes come into their own. But the requirements for moving them, particularly over large distances at wind farms, have increased over the last few years. Oliver Schwenkkrauß has been working on the design of crawler crane undercarriages for 10 years. He has particularly focused on the requirements for the travel gear for moving the crawler crane so as to reduce the stresses which occur during this process and therefore minimise wear. He shares his tips with you.

Crawler cranes are primarily lifting units, but they are also ideal for manoeuvring on site. However, if the crane is moved frequently or with heavy equipment on uneven terrain, signs of wear will obviously occur more quickly. In the worst case scenario, cracks may even appear on load-bearing components and the travel gear may suffer permanent damage. The travel gear on the crawler carrier consists of a travel drive with sprockets, cast base plates and hardened track rollers. It is simply not possible to prevent wear on these components as a result of the high stresses on the steel-to-steel contact surfaces. The service life of the components mainly depends on the following factors:

- Ground conditions of the site track: Is the track level? Is it made of concrete, timber, gravel or sand?

- Length and direction of the distance to be covered: Is the route straight or does it include curves?

- Weight (basic machine/equipment/load) and centre of gravity of the crane

- Maintenance and cleaning of the crane’s travel gear

Ground conditions

The crawler crane should always be moved on a horizontally levelled surface with adequate load bearing capacity. Delves, bumps, ruts, tracks that fall away to the side and other types of unevenness must be avoided as the whole weight of the crane will then no longer be borne by all of the track rollers and components may only be stressed on one side. This will increase wear on the track rollers and base plates. The cost of levelling tracks may be significant, but it is always a worthwhile exercise.

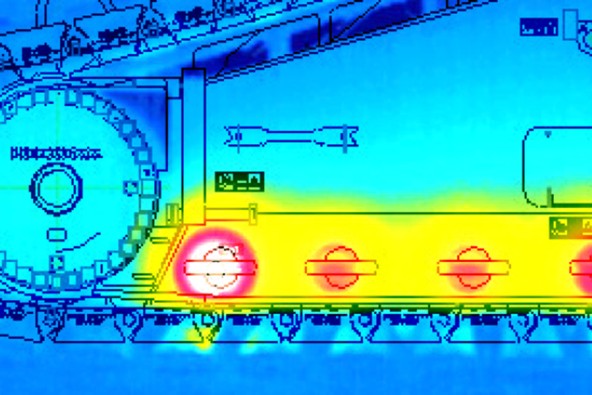

Hot stuff! The camera shows exactly where things are heating up.

Monitor the temperature

Overheating increases wear. We therefore recommend that you monitor the temperature on the travel drive and the crawler carrier’s track rollers, particularly the outer track rollers, during the manoeuvre. A thermal imaging camera or an infrared thermometer may be used for this purpose. The travel drive must not exceed a temperature of maximum 90°C for any length of time. The place to measure the temperature is between the gearbox and brake. The temperature of the track rollers should never exceed 100°C.

Regular maintenance

Clean the crawler chains at regular intervals and remove any materials which may increase wear such as sand, mud and stones. It is also important to check the chain tension at regular intervals. If the chain tension can no longer be adequately achieved using the chain tensioning cylinder, a base plate must be removed. Once this becomes impossible, components will have to be replaced. And last but not least, ensure that everything is properly lubricated. The track rollers and sprockets are greased by the automatic lubrication system. Check the lubricant level at regular intervals and also check the system for leaks and signs of damage.

We want to ensure that you can operate your crane for as long as possible. With this in mind, we have compiled some more detailed information on this topic. The download is available here on our website.

This article was published in the UpLoad magazine 02 | 2021.